40

is sucked o

ut

until the /eI'el reaches Ihe

small

diameter hole. A precise

oil

Jerel

ca

n be achiel'ed with this simple

device.

10.

Allow the oil to settle completely and recheck

the oil level measuremenL Adjust the oil level

if

necessary.

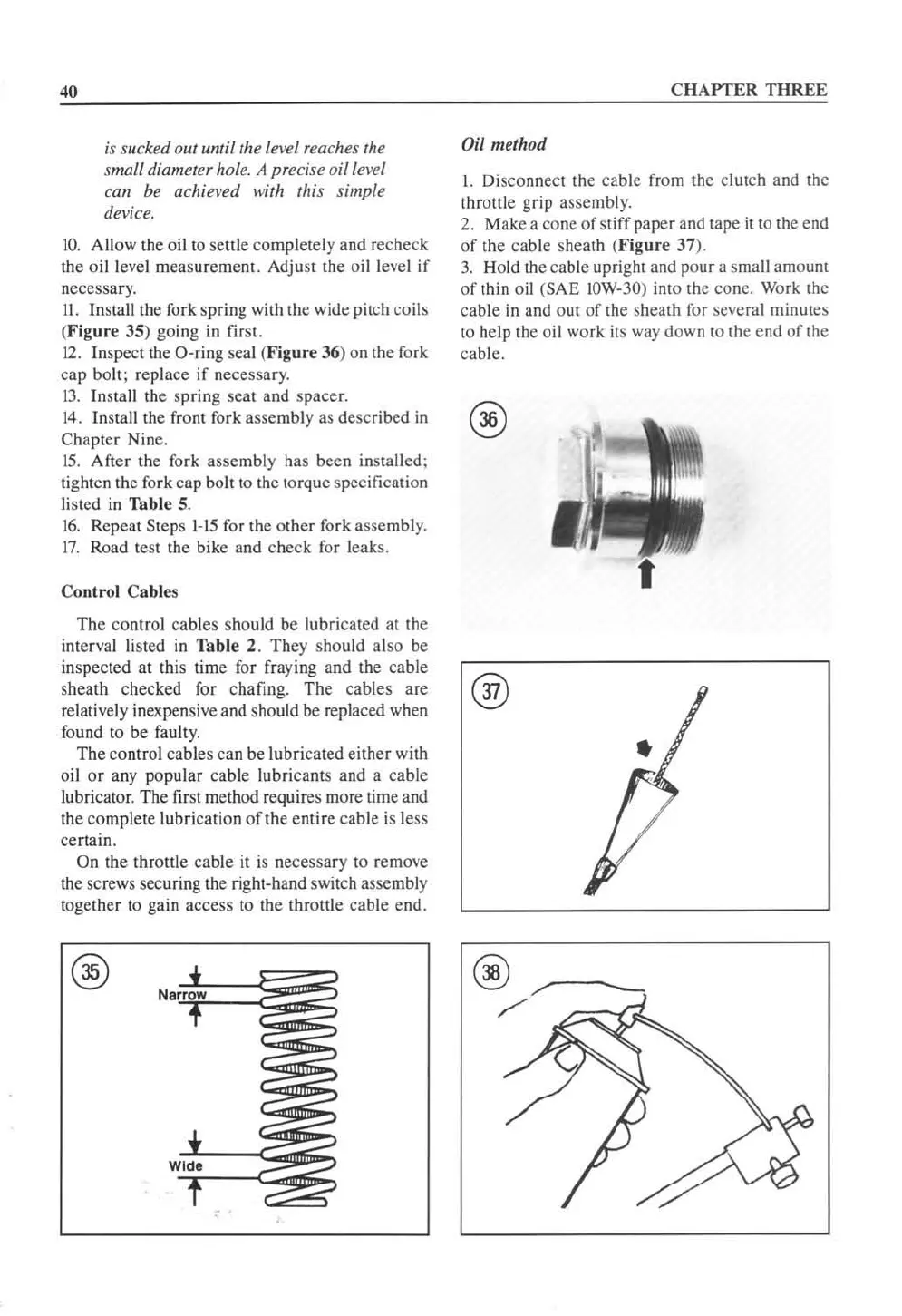

II

. Install the fork spring with the wide pitch coils

(

Figure

35

) going

in

first.

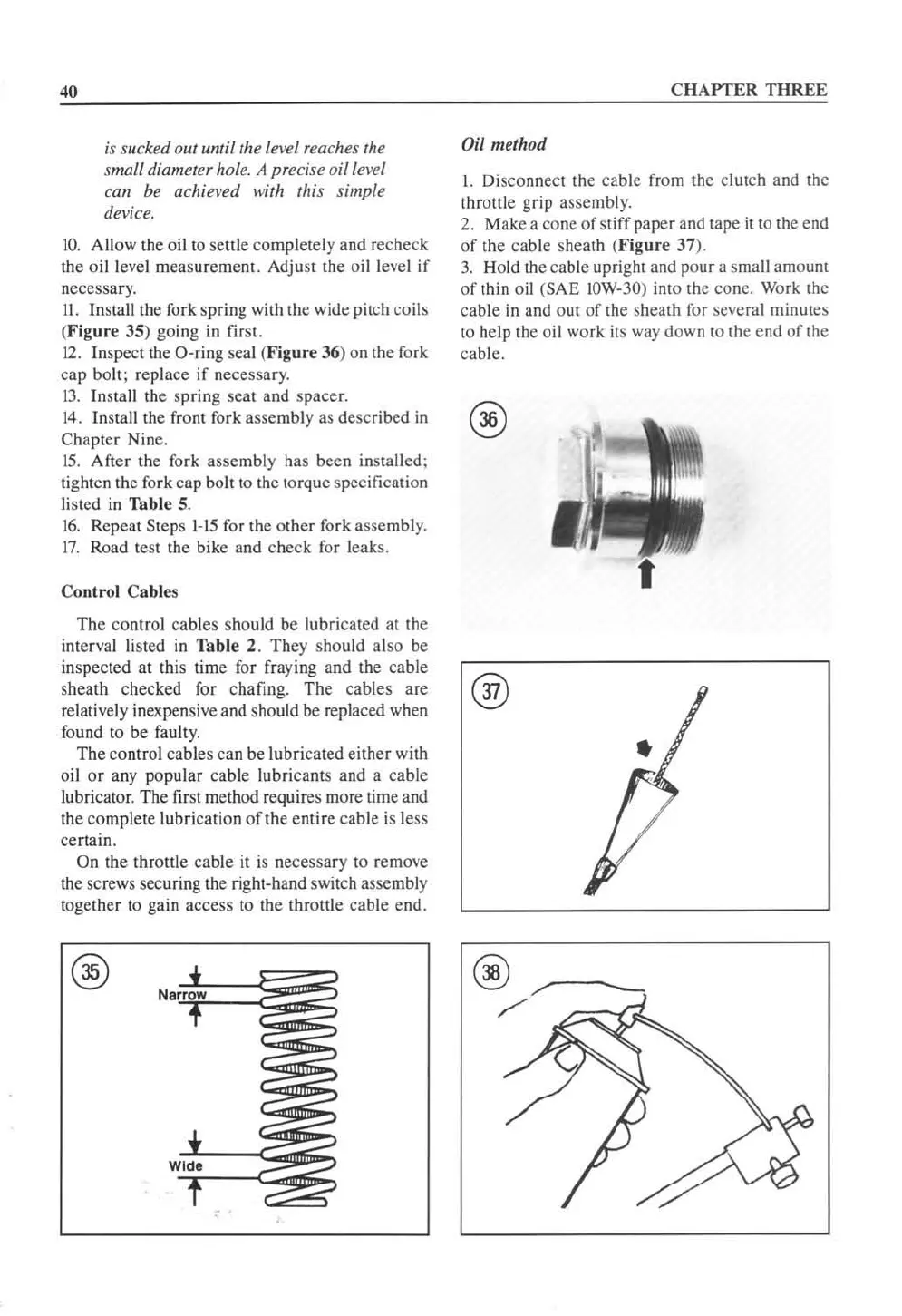

12.

In

spect the O-ring seal (Fi

gure

36

) on the fork

cap bolt; replace

if

necessary.

1

3.

Insta

ll

the spring seat and spacer.

14

.

In

sta

ll

the fro

nt

fork assembly as described

in

Chapter Nine.

1

5.

After the fork assembly has been installed:

ti

ghten the fork

cap

bolt to the torque specification

listed in Table

5.

1

6.

Repeat Steps

1-15

for the

other

fork assembly.

17

. Road test the bike and check f

or

l

ea

k

s.

Contro

l

Ca

bles

CHAPTER

THREE

Oil method

I. Disconnect the

cable

from the clutch and the

th

rottle grip assembly.

2.

Make a cone

of

stiff paper and tape it to the

end

of

the

cable

sheath (

Figure

37

).

3.

Hold the cable upright and pour a small amount

of

thin oil (SAE

IOW

-30) into the cone. Work the

cab

le

in

and out

of

the sheath

fo

r several minutes

to help the oil work its

way

down to the end

of

the

cable.

The control cables

sho

uld be lubricated at the

interval listed

in

Table 2. They should also

be

inspected at

th

is time for fraying and the cable

sheath checked for chafing. The cables are

@

relatively inexpensive and should be replaced when

found to be

faulty.

The

con

trol cables can

be

lubricated either with

oil

or

any popular

cable

lubri

ca

nts and a

cable

lubricator. The first method requires more time and

the

co

mplete lubrication

of

the entire

cab

le is less

certain.

On

the

throttle cable

it

is necessary to remove

th

e screws securing

th

e right-hand switch assembly

together

co

gain access

to

the Ihrallie cable end.

Loading...

Loading...