194

16.

Make sure the tab on the diaphragm assembly

is positioned correctly in the groo

ve

in

the

ca

rburetor body (

Figure

35).

Pu

sh up

on

the

pislon

valve

JUSt

cnough so the re

is

no crease in the

diaphragm lip.

1

7.

Insta

ll

the diaphragm assembly spring.

18.

Install the carburetor

lOp

cap and screws. Be

sure

to

install the throttle cable clamp

(B.

Figure

7)

in

the correct place

as

nOled

during disassembly.

Cleaning

and

Inspection

I. Clean all parts, except rubber

or

plastic parts.

in

a good grade

of

carburetor cleaner. This soluti

on

is available at most automotive

or

motorcycle

supply slores

in

a small. resealable tank with a dip

basket for just a

few

dollars. If

it

is

tightly sealed

when

nOi

in use. the solution will

la

st for several

cleanings.

Fo

llow the manufacturer's instructions

for correct soak time

(usually about 1/2 hour).

2.

Rcmove a

ll

parts from the cleaner and blow dry

with compressed air.

Blow out the

je

ts and needle

jet hold

er

with compressed air. ®

CAUTION

If

compressed air

is

not ami/able,

allow the parts to air dry or use a

clean, lint-free cloth. Do not use a

paper

towel

to

dry

carburetor parts, as

small paper particles may plug

openings

in

the

ca

rburetor body or

jets.

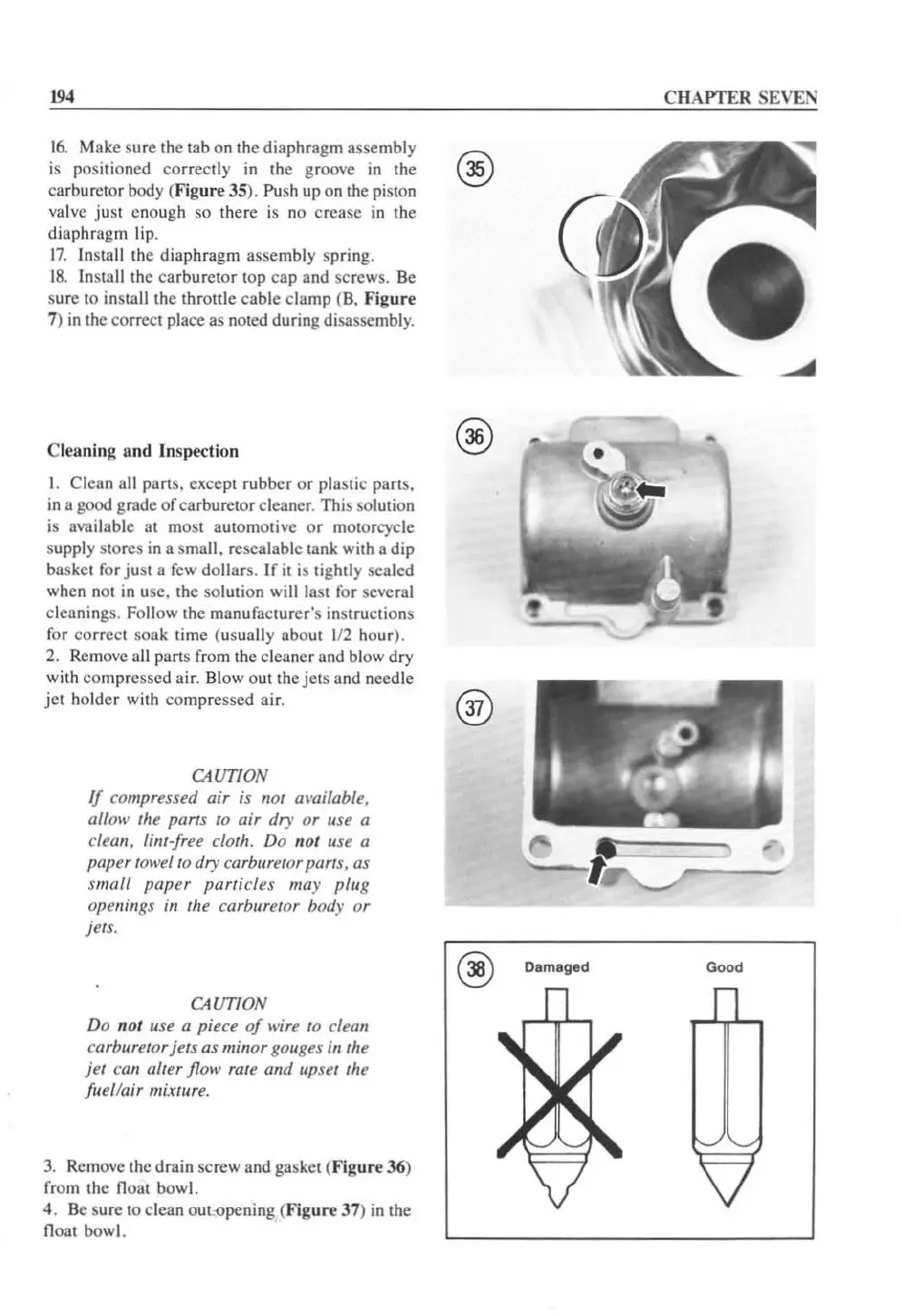

CAUTION

Do nol use a piece

of

wire

to

clean

carburetor jets as minor

gouges

in

the

je

t can alter flow rate and

up

set the

fllellair

mixtllre.

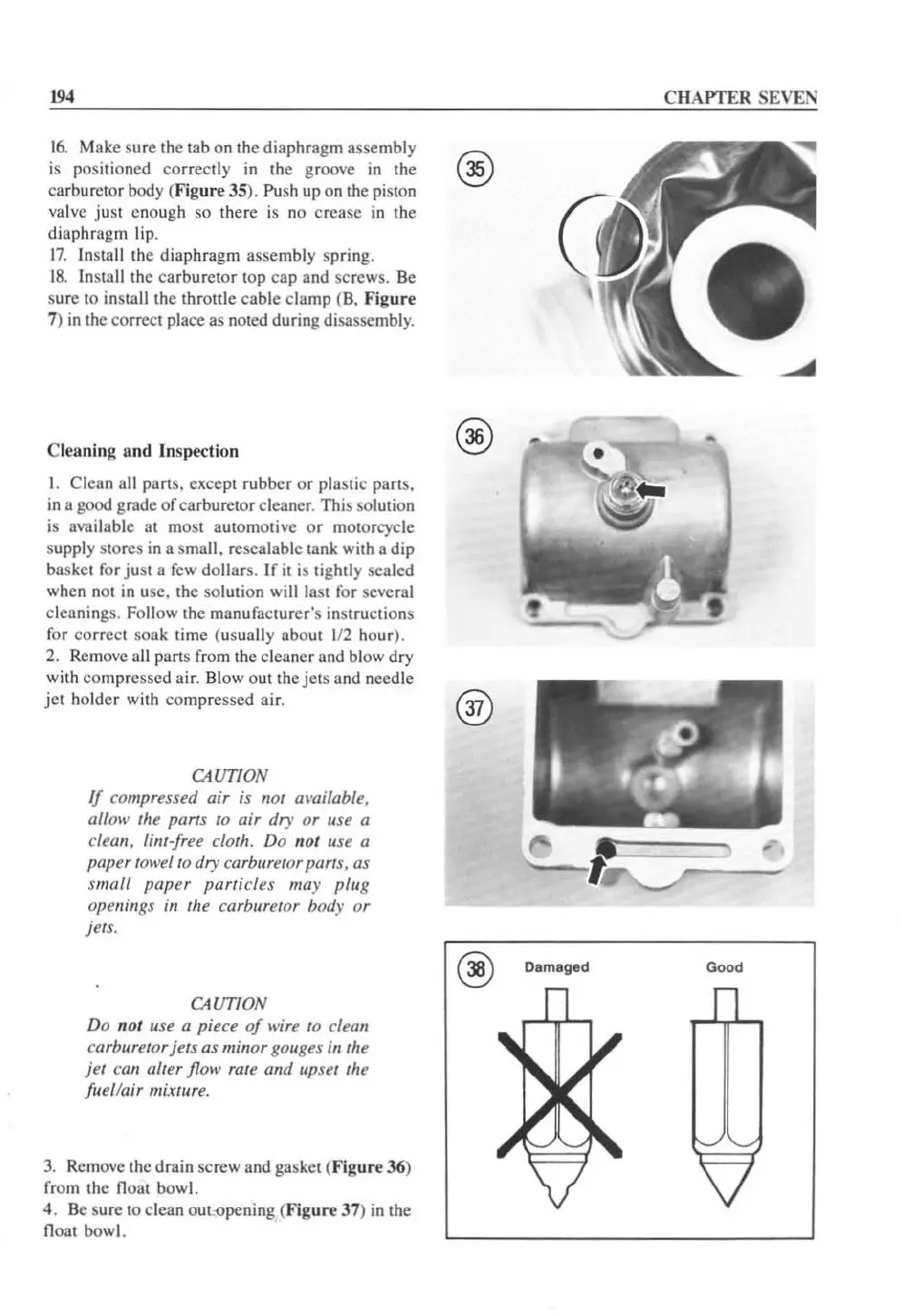

3.

Remove the drain screw and gaSket (Fig

ure

36

)

from the float bowl.

4.

Be

sure

10

clean outopening (

Figure

37)

in

the

float

bowl.

CHAPTER SEVEN

Damagad Good

Loading...

Loading...