ENGINE

31. Pla

ce

a copper washer between the clutch outer

housing and

th

e primary drive gea

r.

This will

prevent the p

ri

mary drive gear from rotat

in

g while

tightening the nut.

CAUTION

The primary drive gear nut has left-

hand

threads.

137

32. Turn the wrench counterclockwise and tighten

the

primary

drive

gear

nut to

the

torque

spec

ifi

cation listed

in

Table 2.

33.

Make sure the O-ring seal (Figure 268)

is

in

place

in

the engine pulley spacer. Apply a light coat

of

grease to the O-ring seal after

it

is

in

place. Slide

the

spacer

onlO the transmission mainshaft with

the O-ring side going

on

first.

34. Insta

ll

the oil control orifice (

Figure

243

) into

the right-hand crankca

se.

35.

Install the cylinder head cove

r,

camshaft.

cy

linder, piston. Slarter clutch assembly and

external gearshift

me

chanism as described

in

this

and

other

related chapters.

36. Install the speedometer drive shaft assembly

(Figure

240) into the crankcase. Tighten the bolt

(F

igure

239

) securely.

37.

In

stall the engine as described in this chapter.

38. Insta

ll

the starter motor and the alternator as

described

in

Ch

apter

Eight.

Crankcase

and

Crankshaft

Inspection

I. Remove the oil gallery plug and gasket (

Figure

269

) from the right+hand crankcase half.

2. Thoroughly clean the inside and outside

of

both

crankcase halves with cleaning solvent.

Dr

y with

compressed air. Make

sure

there is no solvent

residue left

in

the cases as it will contaminate the

new engine oil.

3.

Remove a

ll

old gasket sealing material from

both case half mating surfaces.

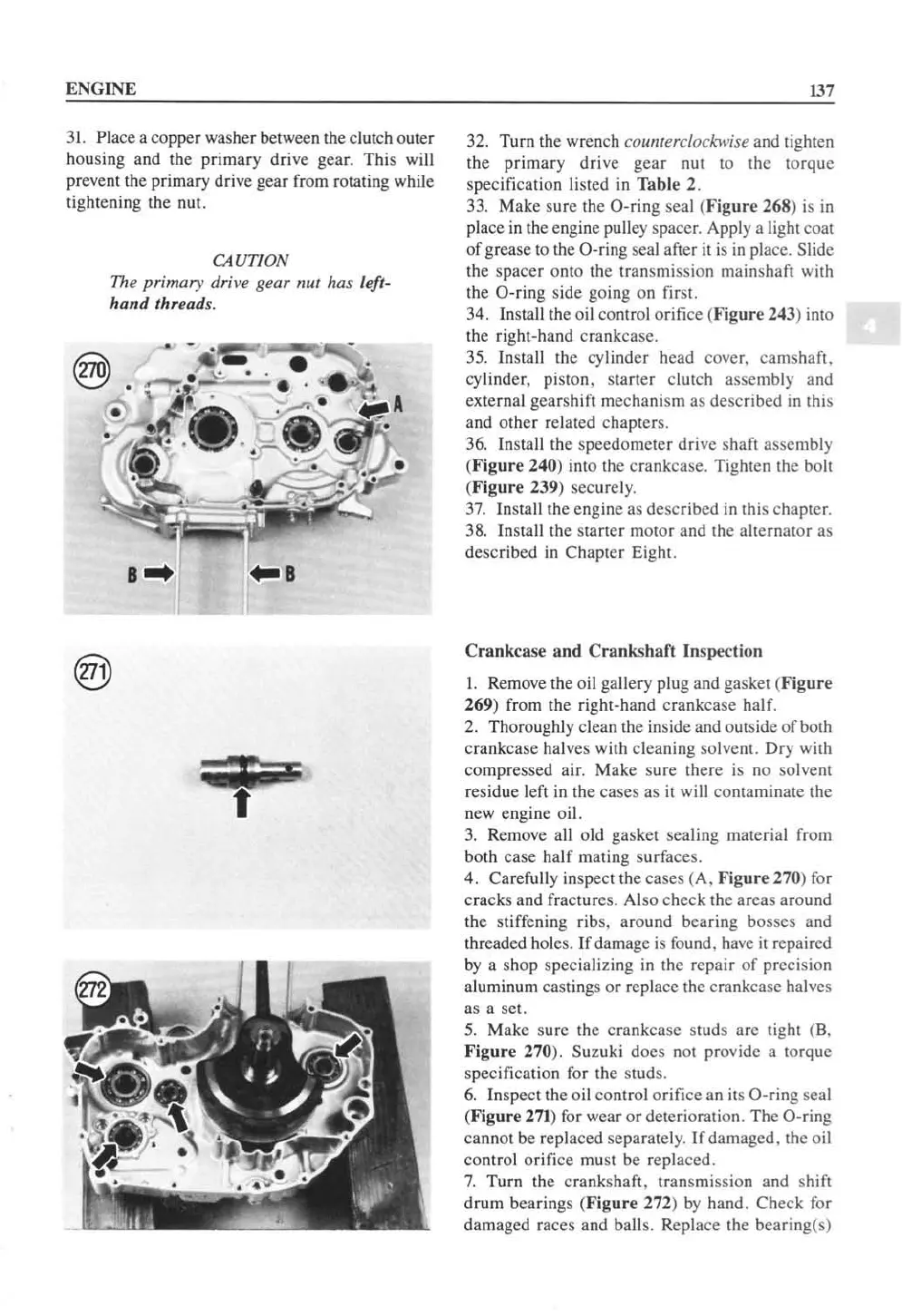

4. Carefully inspect the cases (A.

Figure

270) for

cracks and fractures. Also check the areas around

the s

tiff

en

in

g ribs. around bearing bosses and

threaded holes. If damage

is

found. have it repaired

by

a shop specia

li

zing

in

the repair of precision

aluminum castings

or

replace the crankcase halves

as a set.

5.

Make sure the crankcase studs are tight

(8.

Figure

270). Suzuki does not provide a torque

specification for the studs.

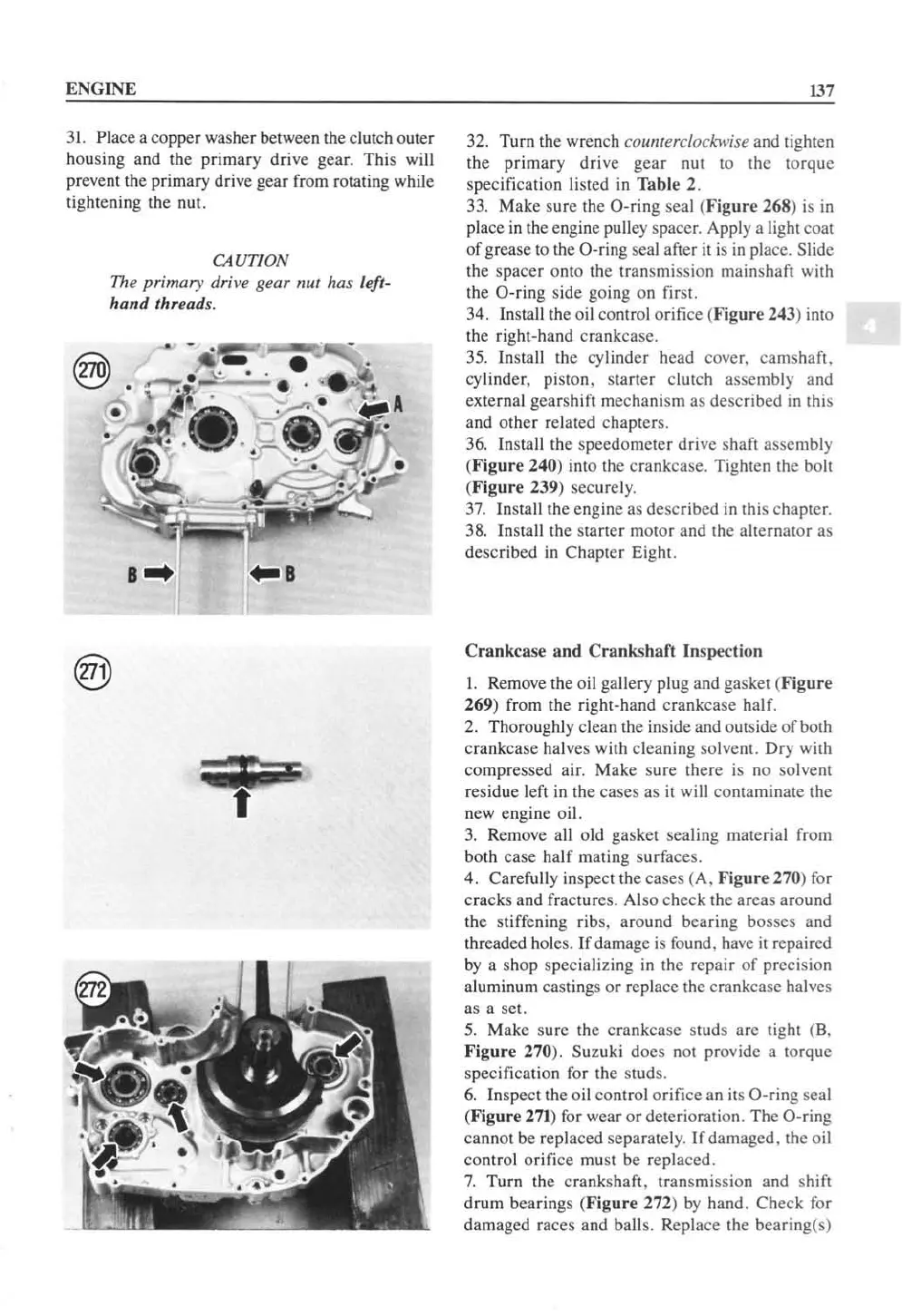

6.

Inspect the oil control

orifice

an its O-ring seal

(

Figure

271

) for wear

or

deterioration. The O-ring

ca

nn

ot

be replaced separately.

If

damaged. the oil

control orifice must be replaced.

7.

Turn the crankshaft, transmission and shift

drum bearings

(F

igure

272)

by

hand.

Check

for

damaged races and ball

s.

Repla

ce

the bearing(s)

Loading...

Loading...