44

Others may raporiz.e and

caust>

b

ra

ke

failure.

Do

nOl

imullli

x differe",

brands or types

of

brake fluid

as

they

may

/1

01

be compatibl

e.

Do no/

intermix a silicone based (DOT

5)

brake fluid as it can cause brake

co

mponelll damage leading

/0

brake

system failur

e.

CAUTION

Be careful when handling brakef1uid.

Do

nOI

spill it

on

paillled

or

plmed

surfaces

or

plastic parts as it will de-

s/r

oy

Ih

e surface. muh

th

e area

immediately with soapy waler and

thoroughly

,il/se it off.

5.

Re

install the diaphragm a

nd

the

tO

P cover.

Tighten the screws securel

y.

Disc Brake Lines

Check brake line between the master cyli

nd

er

and the brake caliper. If there

is

any leakage.

tighten the connections and bleed

th

e brakes as de-

scribed under Bleeding lhe System in Chapler

Eleven. If this docs not stop the leak or

if

a brake

line

is

obviously damaged. cracked

or

chafed, re-

place the brake line and bleed the system.

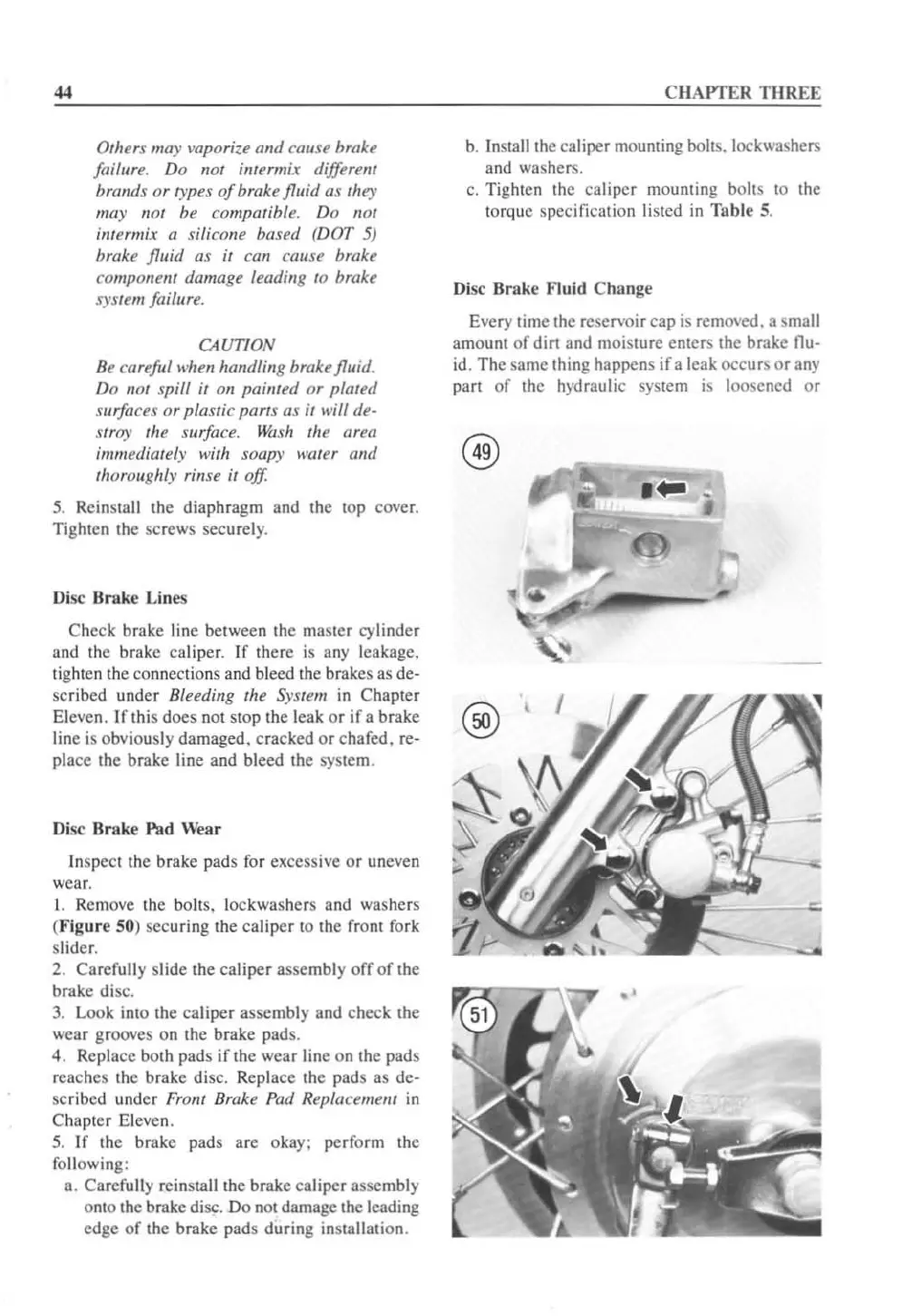

Disc Brake

Pad Wear

Inspect the brake pads for excessive or

un

even

wear.

\. Remove the bo

lt

s. lockwashers and washers

(

Figure

50

) securing the caliper to the front fork

slider.

2. Carefu

ll

y slide the ca

li

per

assembly

off

of

the

brake disc.

3.

Look into the caliper assembly and check the

wear grooves on the brake pads.

4. Replace both pads

if

the wear line on

th

e pads

reac

he

s the brake disc. Replace the pads as de-

scribed under Front Brake Pad Replacement in

Chapter Eleven.

5.

If the brake pads are okay: perform the

foll

owing:

a. Carefully r

ei

nsta

ll

the brake caliper assembly

o

nt

o the brake disc.

Do

not damage the leading

edge of the brake pads during

in

stallation.

CHAPTER

THREE

b.

Install the caliper mounting bolts. lockwashers

and washer

s.

c.

Tighten the caliper mounting bolts to the

torque specification listed in

Tab

le 5.

Disc Brake Fluid

Change

Every time the reservoir cap

is

removed. a small

amount

of

dirt and moisture enters the brake flu-

id

.

Th

e same thing happens

if

a leak occurs or any

part

of

the hydraulic system is loosened

or

;

Loading...

Loading...