8

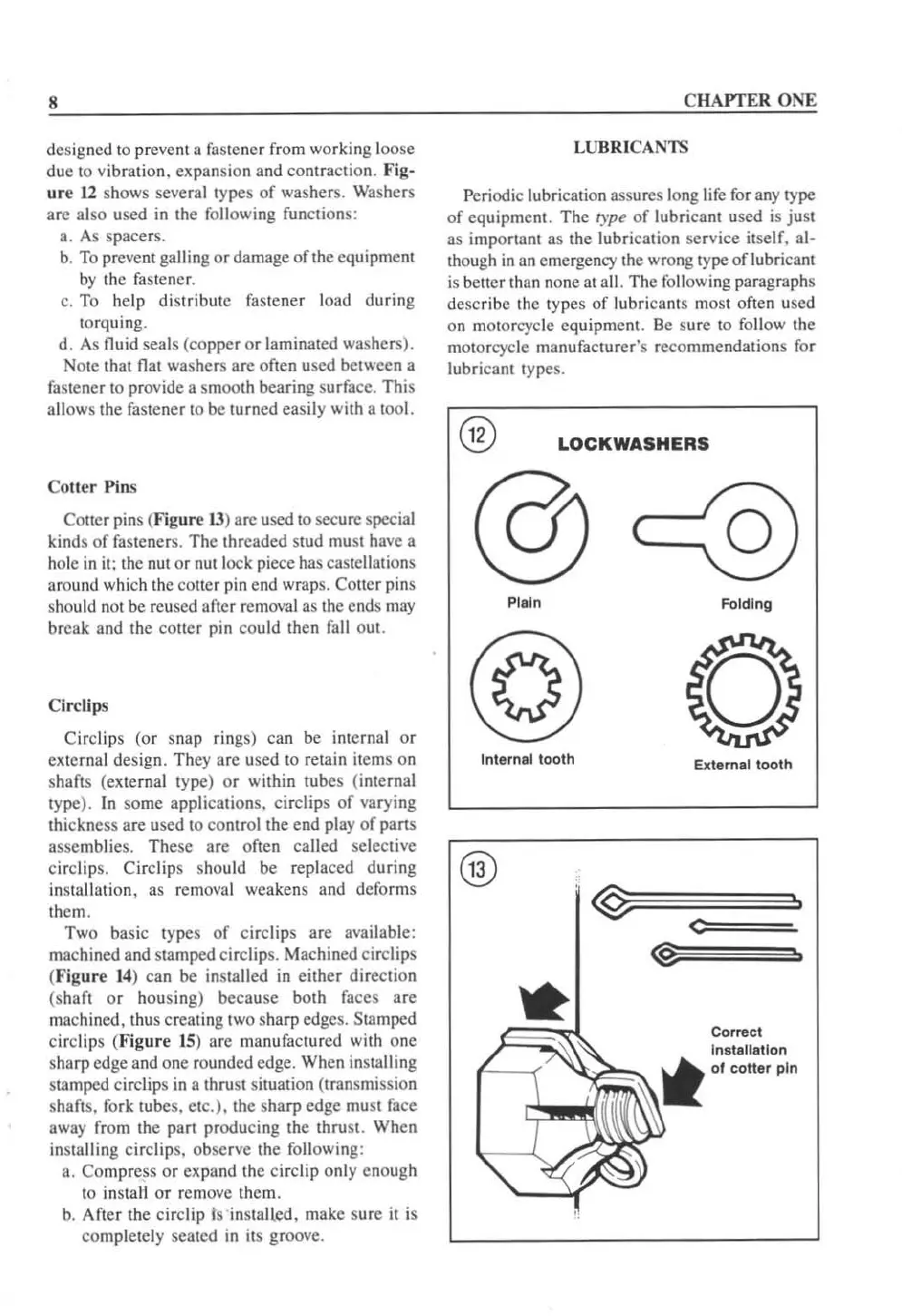

designed

to

prevent a

fa

st

ener

from work

in

g loose

due to vibration. expansion and contraction. Fig-

lire

12

shows several types

of

washers. Washers

arc also used

in

the following functions:

a.

As

spacer

s.

b.

To

prevent

ga

ll

ing

or damage of

the

equipment

by

the

fa

stener.

c. To help distribute

fas

tener load during

torquing.

d.

As

nuid seals (copper or laminated washers).

Note that flat washers are often used between a

fastener to provide a smooth bearing surface. This

a

ll

ows the fastener to

be

turned easily with a tool.

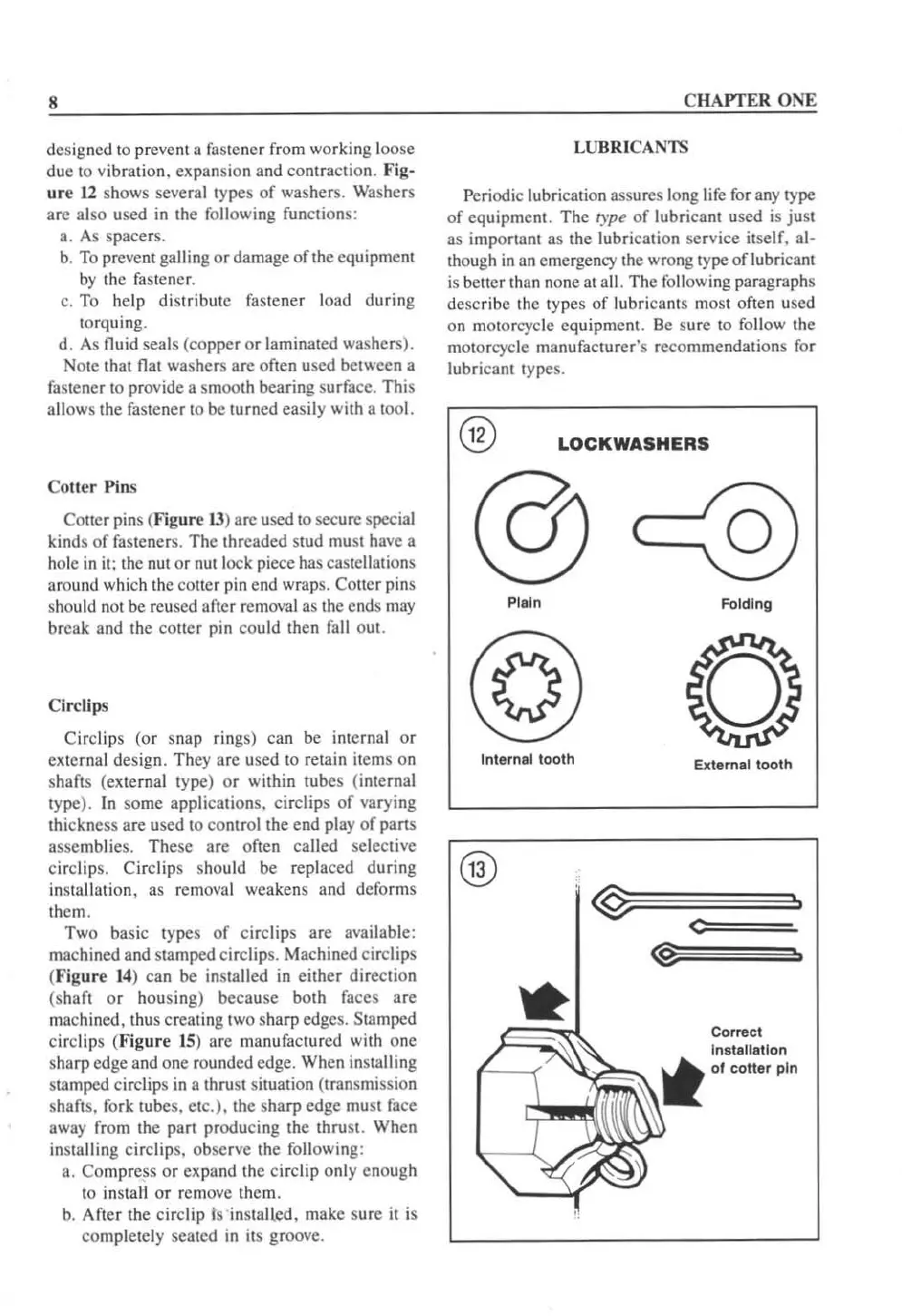

Cotter Pins

COlter pins (

Figure

13

)

arc

used to secure special

kinds of

fas

teners. The threaded st

ud

must have a

hole

in

it; the

nut

or

nut

Jock

piece

has

castcllations

around whi

ch

the cotler pin end wrap

s.

Colter pins

sho

ul

d not be reused after removal as t

he

ends may

break and the

cOlier pin cou

ld

then

fa

ll

out.

Circlips

Circlips (or snap rings) can

be

intern

al

or

external design.

Th

ey

arc used to retain items on

shafts (external type)

or

within tubes

(i

nternal

type).

In

SQ

me app

li

cations. circJips

of

varying

thickness are used to

co

ntrol the end play

of

parts

assemblies.

Th

ese are often called selec

ti

ve

circlip

s.

Circlips should be replaced

du

ring

installation, as removal weakens and deforms

them.

Two basic types

of

circlips are available:

ma

chined and stamped circJips. Machined circJips

(

Figure

14

) can be insta

ll

ed in either direction

(s

ha

ft

or

housing) because both faces are

mac

hin

ed. thus creating two sharp edges. Stamped

circlips

(F

igure

15

) arc manu

fac

tured with one

sharp edge and one rounded edge. When installing

stamped circ

li

ps in a thrust situation (transmission

shafts. fork tubes. etc.). the sharp edge

mu

st face

away from the part produ

ci

ng

the thrust. When

in

sta

ll

ing circlips, obser

ve

the

fo

ll

owing:

a.

Co

mpress or expand the circlip o

nl

y enough

to install

or

remove them.

b. After the circlip

Is installe

d.

make sure

it

is

completely seated

in

its groove.

CHAPTER ONE

LUBRICANTS

Periodic

lu

brication assures long

li

fe

for any type

of equipment. The

l)'pe

of

lubricant used is

just

as important as the lubrication service itsel

f.

al-

though

in

an emergency the wrong type of lubrica

nt

is

bener

th

an none at all. The

fo

ll

ow

in

g paragraphs

describe the types

of

lubricants most often used

on motorcycle equipment. Be sure to follow the

motorcycle manufacturer's recommendations for

lubricant types.

@

LOCKWASHERS

Plain

Internal

looth

@

Folding

External

tooth

Correct

Inatallatlon

•

01

cotter

pin

Loading...

Loading...