ENGINE

4.

Oi

l the piston pin and install

it

in

the connecting

rod. Slowly rotate the piston pin and check for

radial and axial play (

Figur

e

170

). If

any

play

exists. the piston pin should

be

replaced, providing

the rod bore is

in

good condition.

5.

Measure the

in

si

de diameter

of

the

pi

ston pin

bore with a snap gauge

or

caliper (Figure

171

) and

measure the outside diameter of the piston pin with

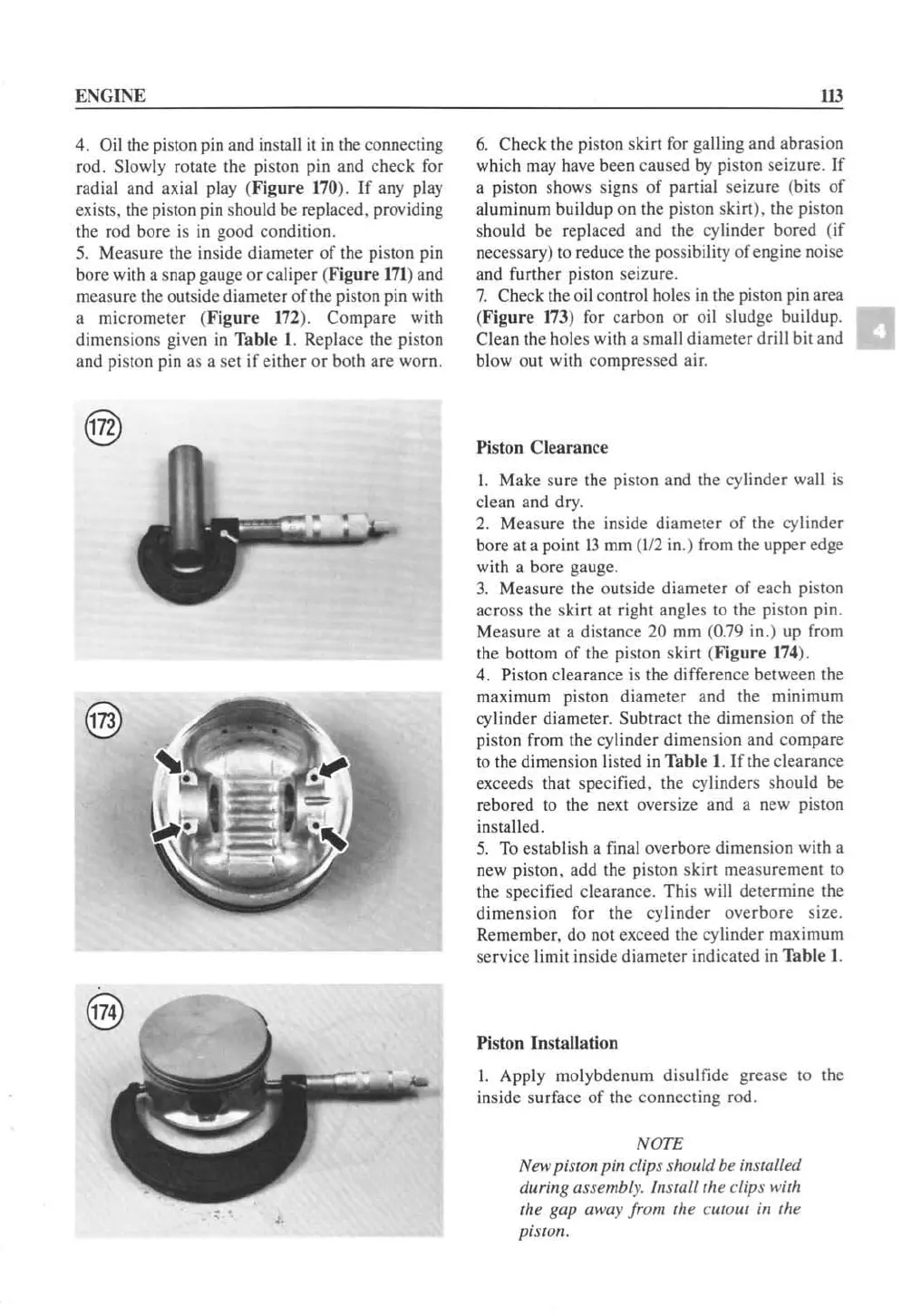

a micrometer (

Figure

172

). Compare with

dimensions given

in

Table

1.

Replace the piston

and

pi

ston pin

as

a set if either or both are worn.

• •

ill

6.

Check the piston skirt

for

galling and abrasion

which

may

have been caused

by

piston seizur

e.

If

a piston shows signs

of

partial se izure (bilS

of

aluminum buildup on the

pi

ston skirt). the piston

sh

ou

ld be replaced and the

cy

linder bored (if

necessary)

to

reduce the possibility of engine noise

and further piston seizure.

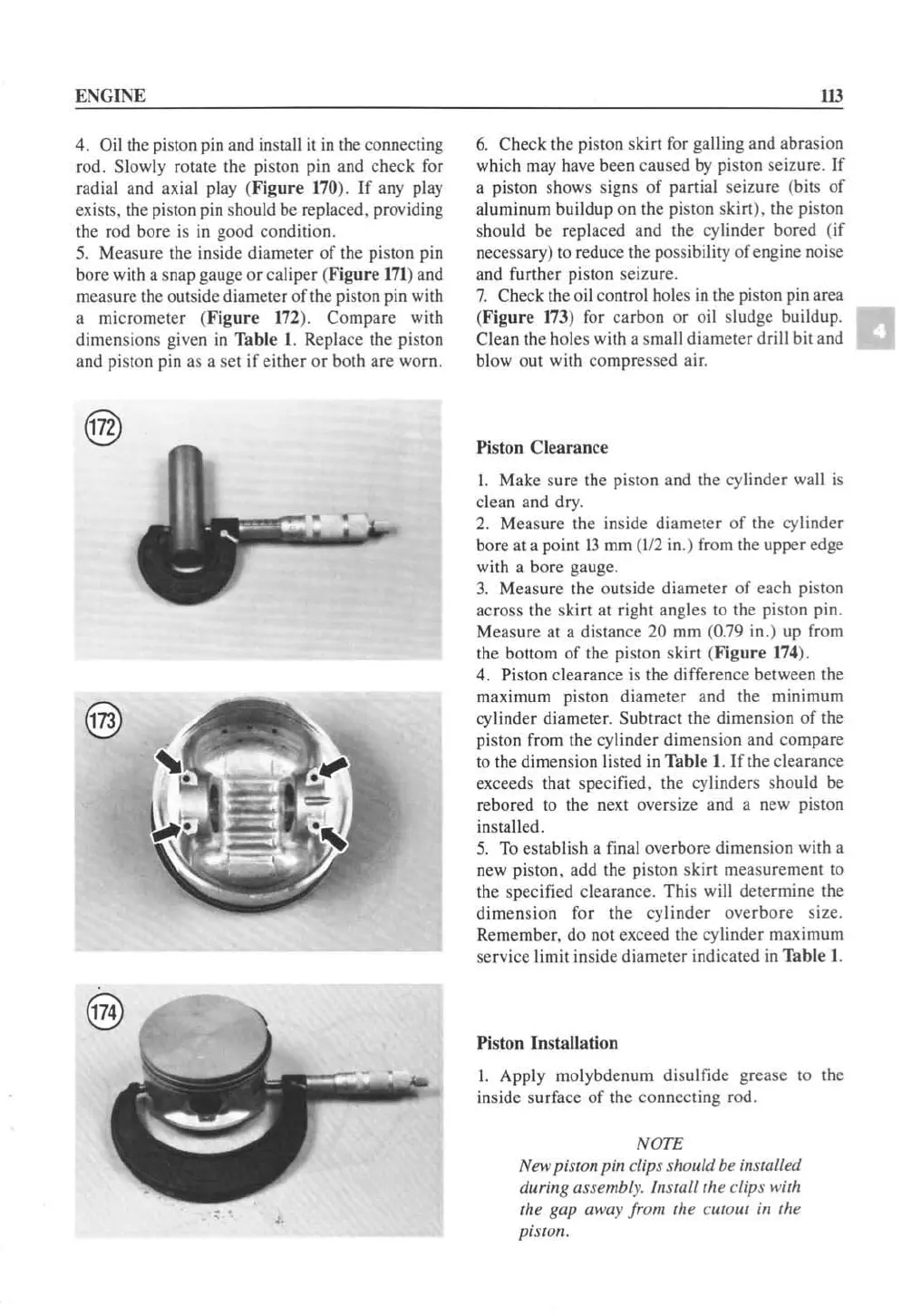

7.

Check the oil control

ho

l

es

in

the piston pin area

(F

igure

173

) for carbon

or

oil sludge buildup.

Clean the holes with a small diameter drill bit and

blowout

wi

th compressed air.

Piston Clearance

I. Make sure the piston and the cylinder wall is

clean and dry.

2.

Measure the inside diameter

of

the

cy

linder

bore at a point 13

mm

(112

in.) from the upper edge

with a bore gauge.

3.

Measure the outside diameter

of

ea

ch

pi

ston

ac

ross the skirt at right angles

to

the

pi

ston pin.

Measure at a

di

stance 20

mm

(0.79

in

.) up from

the bottom

of

the piston skirt

(F

igure

174

).

4.

Pi

ston clearance

is

the difference between the

maximum piston diameter and the minimum

cy

linder diameter. Subtract the dimension

of

the

piston from the

cy

linder dimension and compare

to

the dimension listed

in

Table I. If the clearance

exceeds that specified, the cylinders sh

ou

ld

be

rebored

to

the

next

oversize and a new

pi

ston

installed.

5.

To

establi

sh

a final overbore dimension with a

new piston. add the

pi

ston skirt measurement to

the specified clearance. This will determine the

dimension for the cylinder overbore size.

Remember, do not exceed the

cy

linder maximum

service limit inside diameter indicated in Table

I.

Piston Installation

I. Apply molybdenum

di

su

lfide grease

to

the

inside

su

rface

of

the connecting rod.

NOTE

New piston pin clips should be installed

durillg assembly.

hutoll

the clips with

the gap away from the

cutout ill the

piston.

Loading...

Loading...