106

8.

If

the

CO

nla

et

area is too low on Ihe

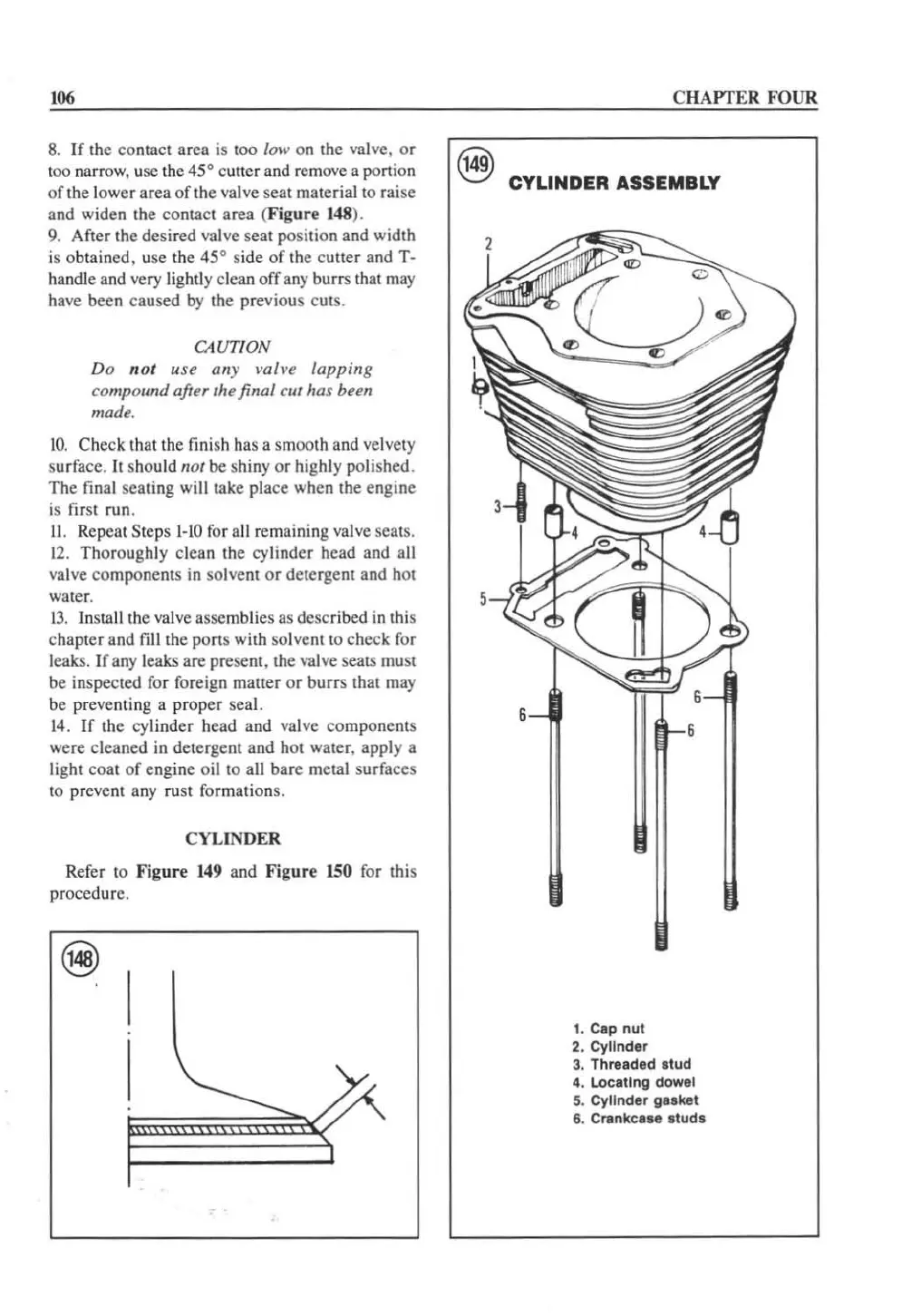

va

lve.

or

100

narrow

, u

se

the 45° cutter and remove a

ponio

n

of

the lower area

of

lhe

va

l

ve

seal material to raise

and widen

th

e contact area (

Figure

148

).

9.

After the desired

va

l

ve

seat position and width

is obtained, use the

45° side of the cutter and

T-

ha

ndl

e and very

li

ghtly clean

off

any burrs

th

ai

may

have been caused

by

the previous cuts.

CAUTION

Do

not

use

any va

lve

lapping

compound after the final cut has

bun

made,

1

0.

Ch

ec

k that

th

e finish h

as

a smooth and velvety

s

urf

ace. It sh

ou

ld

not be sh

iny

or highly polished.

The final seating will take place when the engine

is first run.

11

. Repeal

SICPS

1-

10

fo

r

all

rema

in

ing

va

l

ve

se

al

s.

12.

Thoroughly clean the cylinder head and a

ll

va

l

ve

components

in

sa

lven! or detergent and hot

water.

13

.

In

stall the

va

l

ve

assembl

ie

s as described

in

this

chapter and fill the ports with solvent to check

fo

r

leaks.

If

any leaks are present, the valve seats must

be

inspected for

fo

reign matter or burrs that may

be preventing a proper seal.

14

. If the cylind

er

head and valve components

were cleaned in detergent a

nd

hot water, apply a

light

coal

of

engine oil to a

ll

bare metal surfaces

to preve

nt

any

ru

st formations.

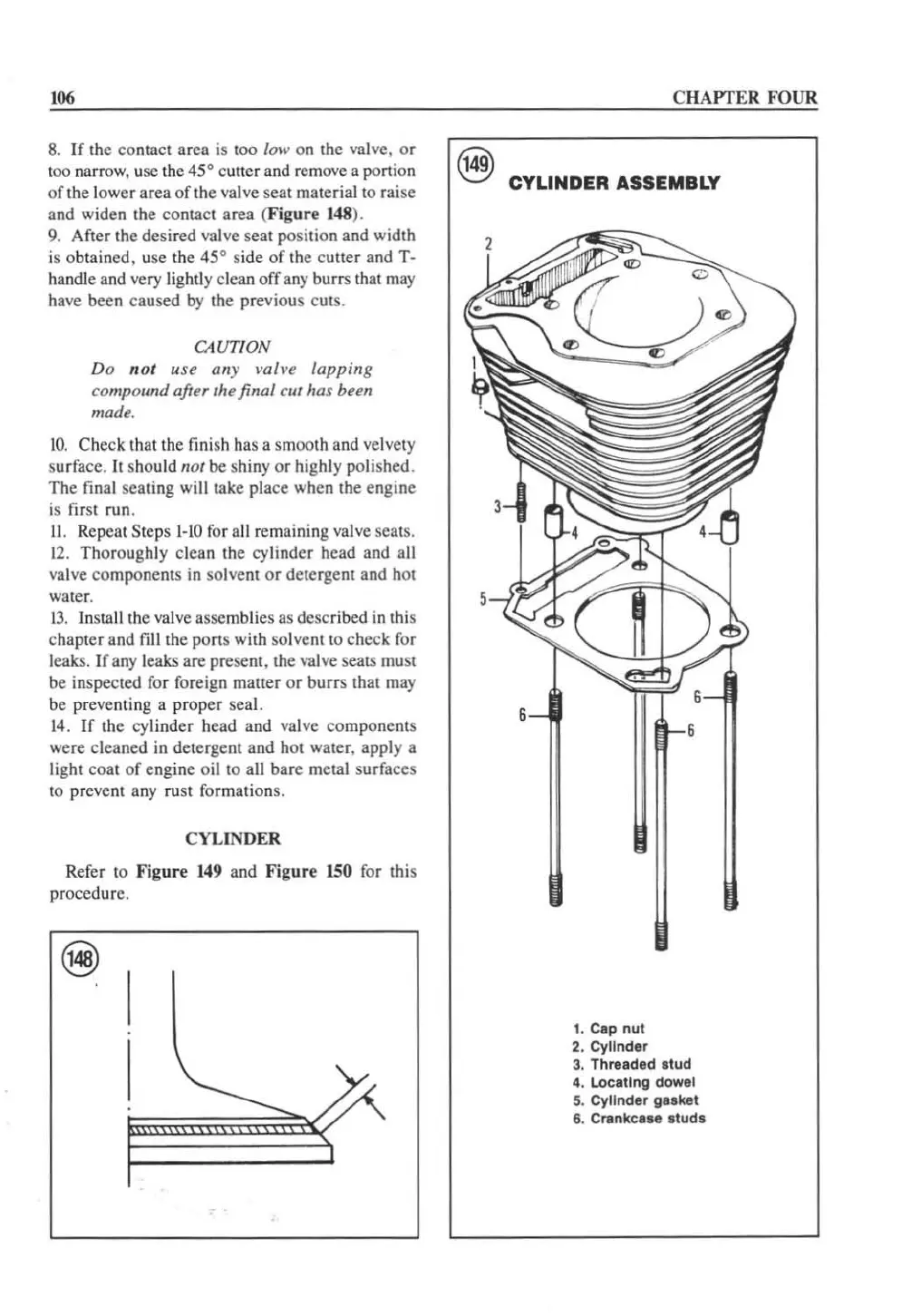

CYLINDER

Refer to

Figure

149

and

Figure

150

for this

procedure.

CHAPTER FOUR

r,4g\

\!:;!I

CYLINDER

ASSEMBLY

1. Cap nut

2.

Cylinder

3.

Threlded

stud

4. Locltlng dowel

5.

Cylinder

gllket

6.

Crankclle

studs

Loading...

Loading...