ENGINE

@

'.

10

9

Inspection

The

following procedure requires the use of

h

ig

h

ly

specialized and expensive measuring

instruments. If such equipment

is

nOl

readily

available. have the measurements performed by a

dealer

or

qualified machine shop.

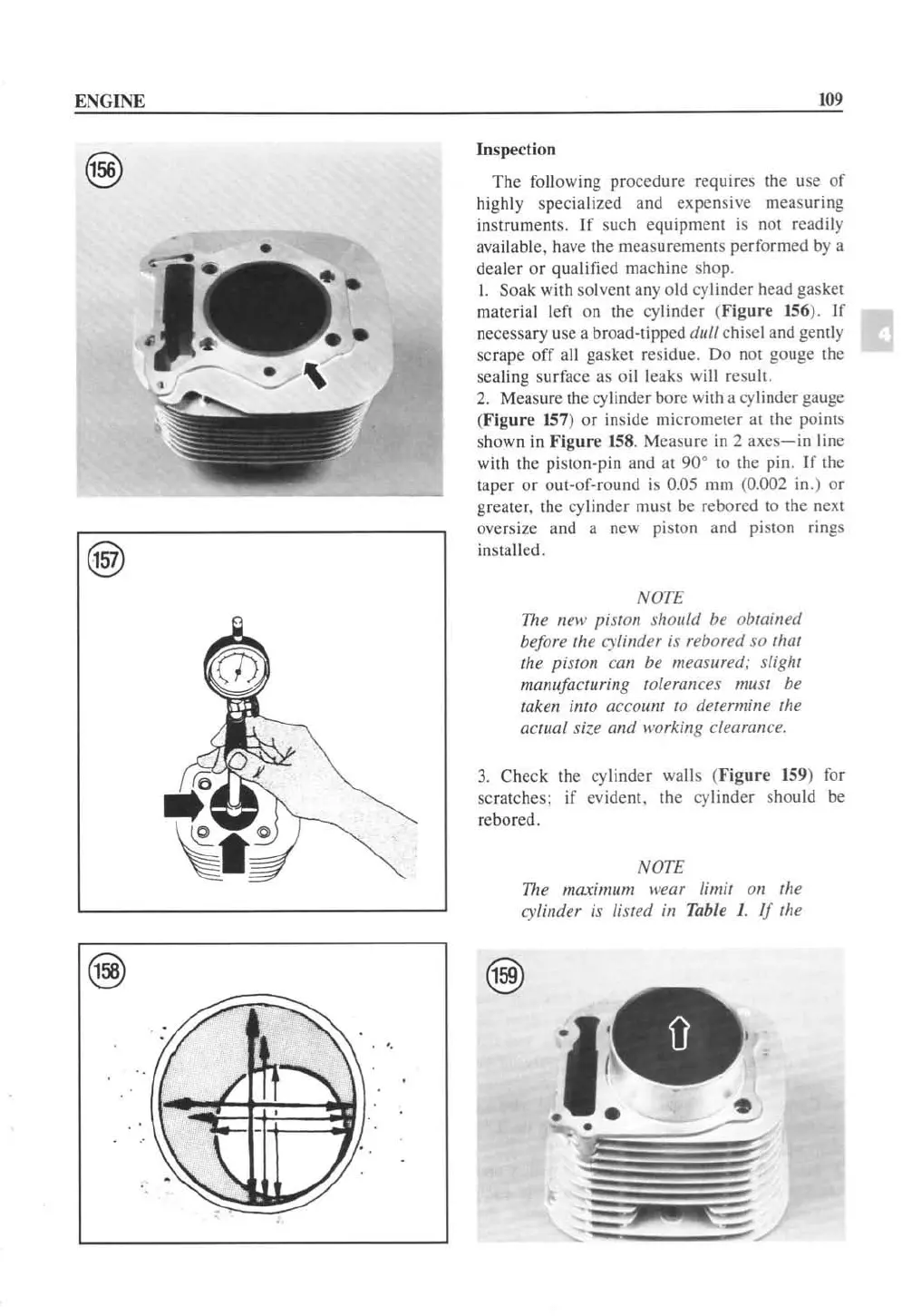

\.

Soak with solvent any o

ld

cylinder head gasket

material

IcC!

on the cylinder (Figu

re

156). If

necessary usc a broad-tipped (filII chisel and gently

scrape

off

all gasket residue. Do

nOI

gouge the

scaling surface as o

il

leaks will resulL

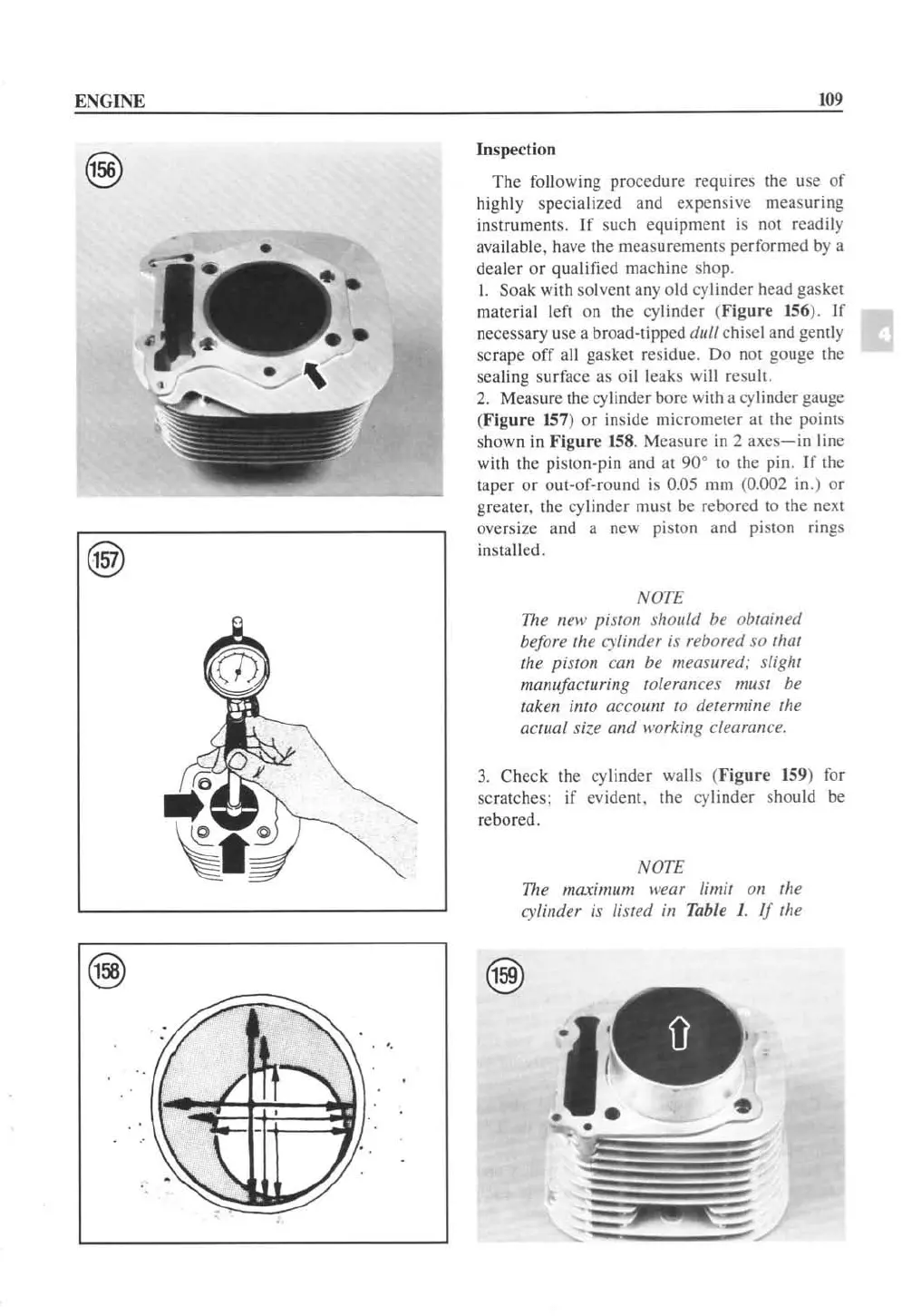

2.

Measure the

cy

linder bore with a cylinder gauge

(

Figure

157

) or inside micrometer al the points

shown

in

Fig

ure

158. Measure

in

2

axes-in

line

with the piston-pin and at

90

° to the pin. If the

taper

or

out-of-round is 0.05

mm

(0.002 in.) or

greater. the cylinder must be rebored to the next

oversize and a new piston and piston rings

installed.

NOTE

The

new pisto/l shollld be

obra

ined

before

,he

£.)'Ii

llli

er is rebornl so ,hm

the piston can be measllred: slight

manufactllring tolerances must be

raken

illto account

to

determine the

actllal size and working clearance.

3.

Check the

cy

linder walls (Fig

ur

e 159)

ro

r

scratches; ir evident. the

cy

linder should be

rebored.

NOTE

The

mluimulII wear limit

Oil

the

cylinder

is listed

in

Table

1.

If

the

Loading...

Loading...