GENERAL

INfORMATION

screw during remom/.

If

blue

wctite

Thread/ocker

(No.

242) is used.

(he

(orque required ( 0 loosen (he fastener

is

110-120

% greater (han

(he

applied

rorque used

ro

ligh(en

th

~

fastene

r.

If

r~d

Loc

r;t

e Thread/ocker

(No.

271)

;s

used.

th

e torque reqllired

to

loosen the

fastener is

200-250% greater than the

applied

rorque

II

sed

ro

tighten the fas-

tener.

Beca

ll

se

of

this facror. lise

wctile.

or equil

'O/e

m . spa

rin

gly as it

wiff

"wke

fastener remOI'af \'ery diffi-

C

II11

if

ro

o milch locking compo

llntJ

is

applied.

I. Use a locking

co

mpound such as Loctite

Threadlocker No. 242

(F

igure

4) on a

ll

boils and

nuts. even if they are secured with lockwashers.

This type of Loctite docs not harden completely

and

allows easy removal

of

the boh or nut. A screw

or bolt lost from an engine cover or bearing

retainer could easily cause se

ri

ous and expensive

damage before its loss is noticed. Make s

ur

e the

threads are clean and

fr

ee of grease and oil. Clean

with contact cleaner before ap

pl

ying the Loctite.

5

When applying Loct

it

e. use a small amount. If too

much

is

used.

it

can work its

way

down the threads

and s

ti

ck

pan

s together not

me

ant to

be

stuck. Keep

a tube

of

both blue (No. 242) and red (No. 271)

Loctite

Thr

eadlocker in

yo

ur

tool box.

Wh

en used

properl

y.

it

is

cheap insurance.

2.

Use a hammer-driven impact tool to rem

ove

and

in

stall all bo

lt

s. particularly engine cover screws.

These tools h

el

p prevent the rounding

off

of

bolt

heads and ensure a tight insta

ll

ation.

3.

When replacing

mi

ss

in

g

or

broken fasteners

(bolts. nuts and screws). especially on the eng

in

e

or

frame components. always use Suzuki replace-

ment

pari

S.

They are specia

ll

y hardened for each

application. The wro

ng

50·cent bolt could easily

cause serious and expensi

ve

damage, not to

mention rider injur

y.

4. When

in

stalling gaskets in the eng

in

e. always

use Suzuki replaceme

nt

gaskets witholll sealer,

unless designated, These gaskets arc designed to

swe

ll

when they come in

co

nta

ct with oil. Gasket

scal

er

will prevent the

gaS

kets from swe

ll

ing as

intended. which can result

in

oil leaks. These

Suzuki

gaskets are cut from material

of

the precise

thickness needed. Installation

of

a too thick

or

too

thin gasket

in

a cri

ti

cal area cou

ld

cause engine

damage.

TORQUE

SPECIFICATI

ONS

Torque specifications througho

ut

this manual are

given

in

Newton meters

(N

'm

) and foot-pounds

(ft.-lb.). Newton meters have been adopted

in

place

of

meter kilograms (mkg)

in

accordance with the

International Modernized Metric System. Tool

manufacturers offer torque wrenches calibrated

in

both Newton meters and foot-pounds.

Existing torque wrenches calibrated

in

meter

kilograms can

be

used by performing a simple

conversion. All

yo

u h

ave

to do is move the deci-

mal point one place to the

right: for example. 4

.7

mkg = 47 N·m. This conversion is accurate

enough for mechanical wo

rk

even though

th

e exact

mathematical conversion

is

3.5

mk

g

.,

34.3 N·m.

Refer

to

Table

2

for

standa

rd to rque

speci

fi

cations for

va

rious size screws. bolts and

nuts that may not be listed

in

the respective

chapters. To use

th

e table. first determine the size

of

the bolt or nut. Use a vernier caliper and

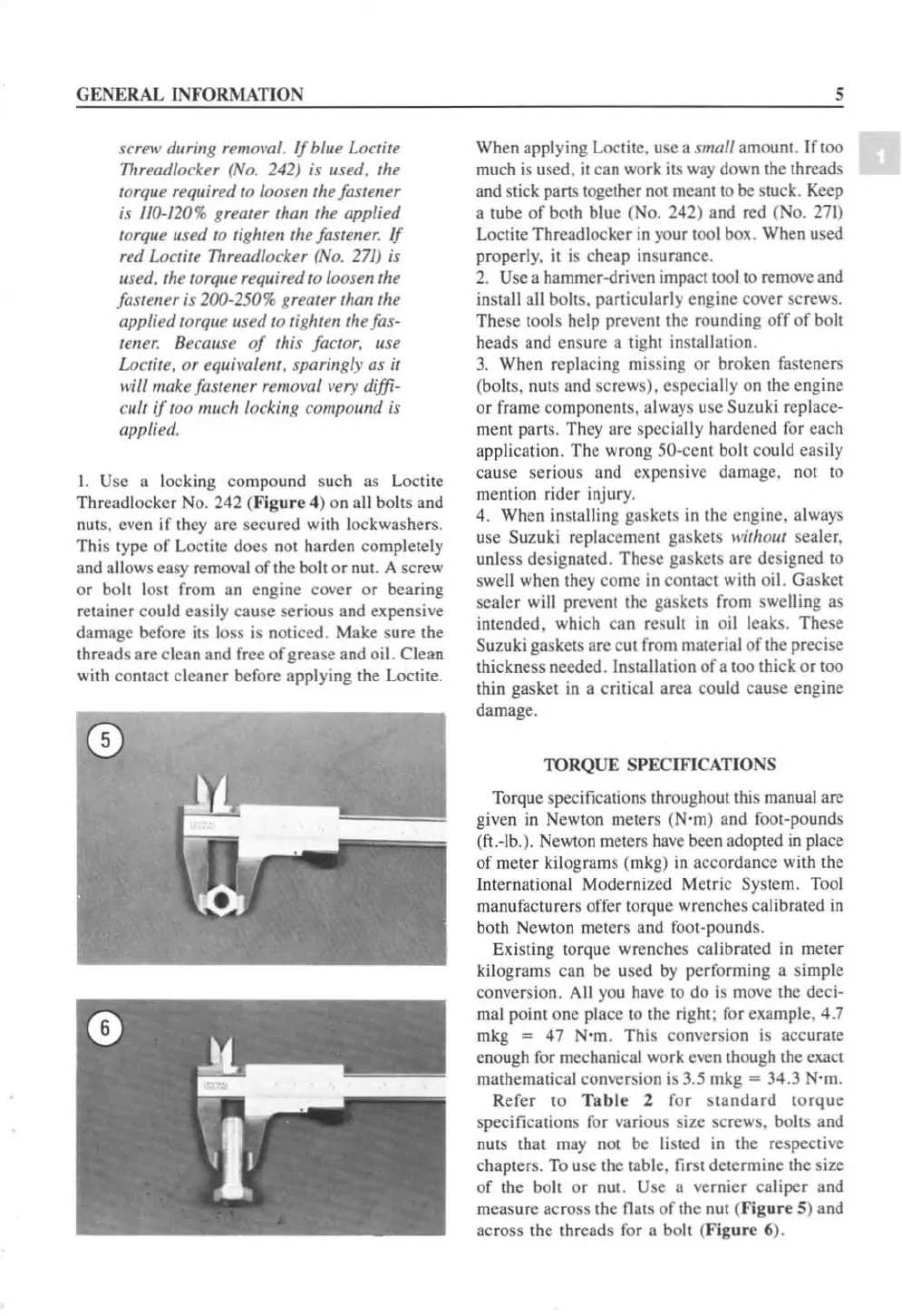

measure across the nats of the nut (

Figure

5) and

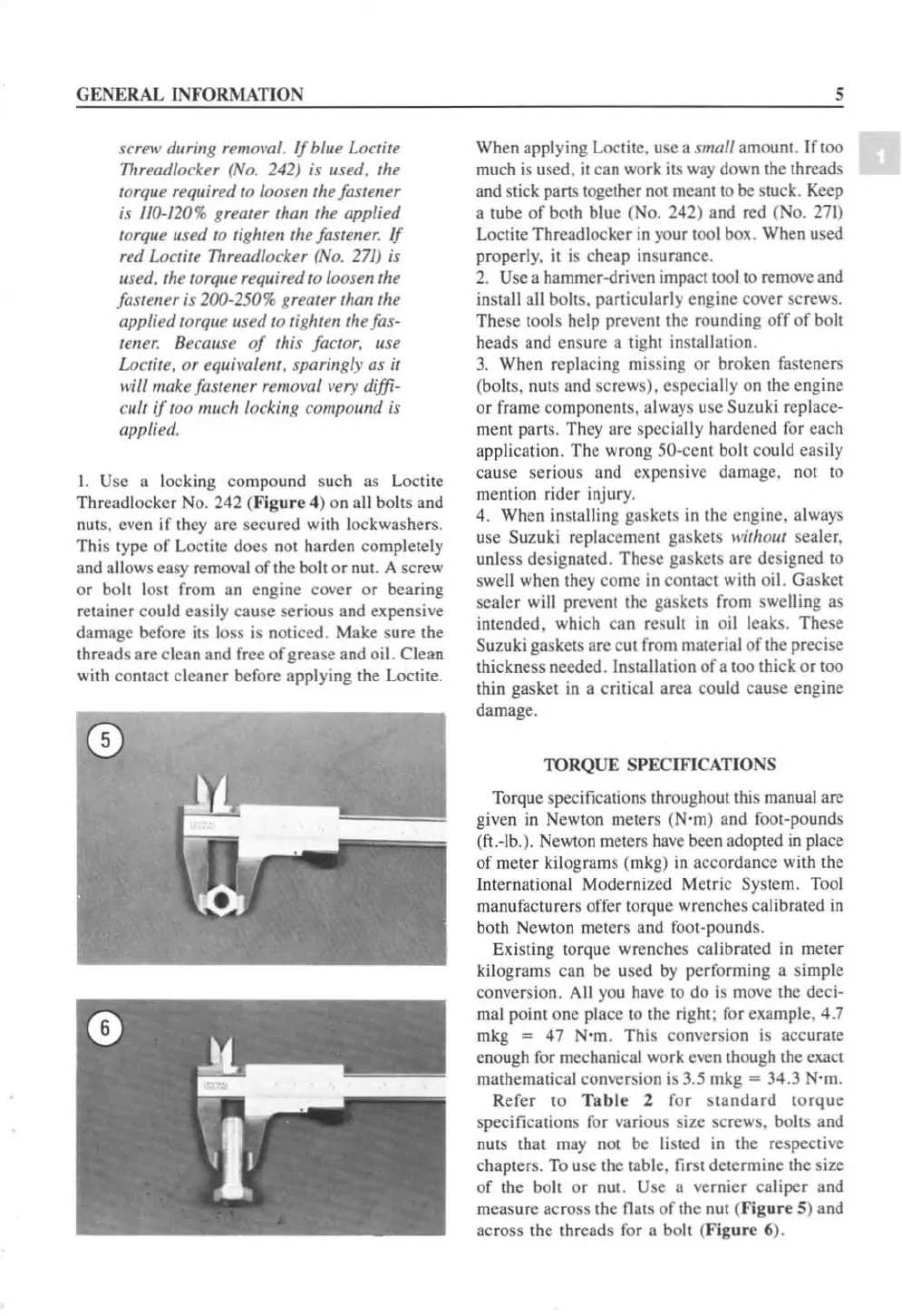

across the threads f

or

a bo

lt

(

Figure

6).

Loading...

Loading...