60

15.

Repeat Step

14

for the intake

\al\'(~s.

16.

Rotate thc engine

sc\c

raJ

complete n!\olulions

and recheck the

\'al\c

clearances. Readjust

if

neces-

sary.

17.

After the

\ah

'cs arc adjusted correctly, recheck

and adjust

if

necessary the automalic

dccomprc~

sion cable as described

in

this chapler.

18.

Inspect the seal (

Figur

e

10..1

) on the

\ahe

ad-

juster covers. rcpl3cc

if

necessary. Install both

co\-

en. and lighten thc bolts securely.

19.

In

spect the O-ring seal on

\al\

c timing inspec-

lion

co\

cr

(Fig

u re

lO

S). replace

if

necessary. Install

the

co\er

on thc left-hand crankcase

co\er

and

tighten securely.

20.

Install the spa

rk

plug and reconnect thc spark

plug leud.

11. Make sure thc mbbcr cushions (

fi

g

ur

e 106)

:lTe

in

place on thc

cylindcrhcad

Icft-hand

cO\crand

lIlslalithc cO\cr.

22.

In

s

tallthc

bolt and

cap

nUl

sccuring the eylin-

dcr

hcad Icft-hand

co\er

(

FiJ!u

re 91). Tightcn thc

bolt and

cap

nUl

sccurcly.

23

. Install thc fucl tank as dcscribed in

Chaptcr

Scvcn.

24.

Install thc scat

as

described

in

ChapterTwelvc.

Co

mpr

ession Test

Pcriodically chcck the cylindcr compression. Re-

cord thc results in thc maintcnance log and

comparc

thcm

to

the results at the ncxt intefval. A

nmning

re-

cord \\

ill shO\\ trends in detcrioration

so

that correc-

tivc

action can be takcn bcforc completc failurc.

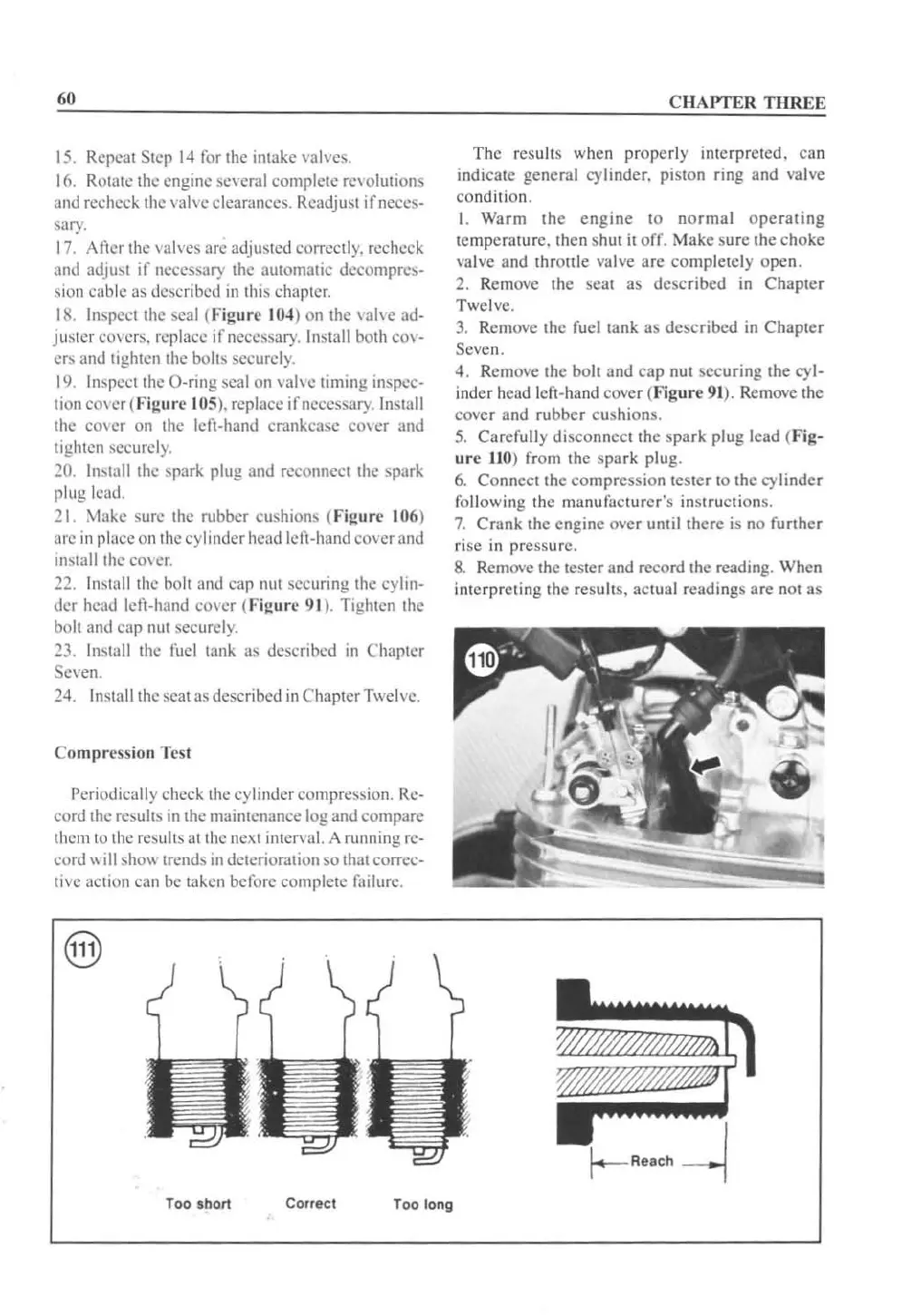

Too short

Corr

ect

Too

tong

CHAPTER THREE

The

results wh

en

properly

int

erprete

d .

ca

n

indicate

gene

ral cylinder.

piston

ring and

vah'e

co

nditi

on.

I.

Warm

the

engine

to

norma

l

ope

ra ting

temp

erature.

then sh

ut

it off.

Make

SUfe

the

choke

valve and

throttle

valve

are

comp

letely

ope

n.

2. R

emove

the

seat

as

desc

ribed in

Chapter

Twelve.

3.

Remove

the

fuel lank as

described

in

Chapte

r

Seven.

4. Remove

the

bolt and

cap

nut

securing

the cyl-

inder head left-hand

cover (Figure

91

). Remove

the

cover and

rubber

cushions.

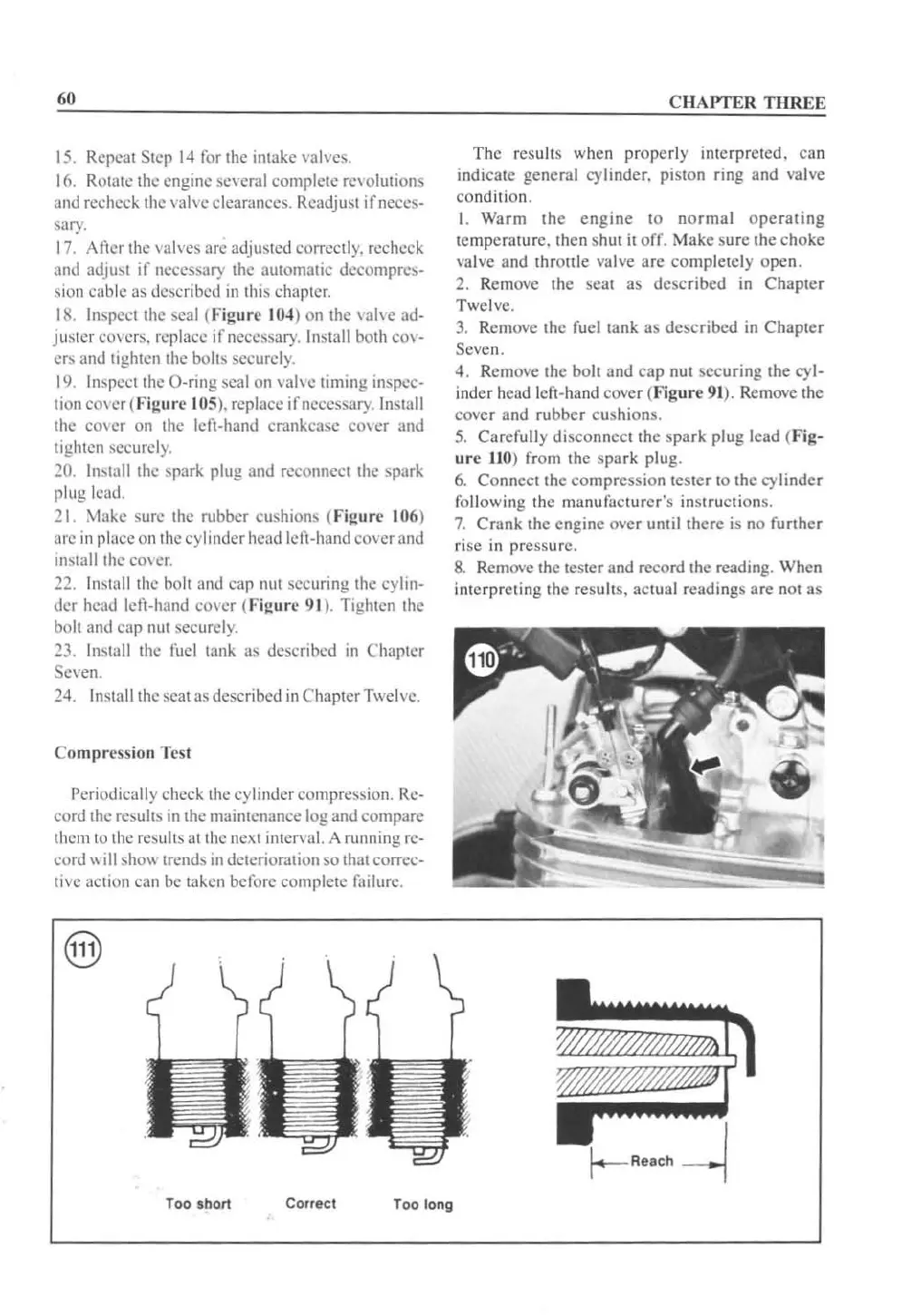

5.

Caref

ully

disconnect

the

spark

plug l

ead

(Fig-

ure

110

) from

thc

spark

plug.

6.

Connect

thc

compression

test

er

to

thc

cylinder

fo

ll

owing

the manufacture

r'

s inst ructions.

7.

Crank

t

he

enginc

over until

there

is

no

further

rise in pressurc.

8.

Remove the tester and record the reading.

When

intcrprcting the res

ul

ts,

ac

tual readings are

nO!

as

Loading...

Loading...