liD

cylinder is

WOn!

to

this limit, the

cylinder

//Illst

be replaced. Neller

rebaTe

a cylifuJer

if

the finished

rebaTe

diameter will be this dimension

or

greater.

NOTE

After hal·ing the cylinder rebaTed,

wash it thoroughly in

hal

soapy water.

This

;s

the best way to clean the

cylinder

of

all fille grit material left

from the bore job. A/ter

II'OShi/lg

the

cylinder,

rIIn

a clean white c/oth

Ihrollgh Ihe cylimJer, (he

cloth

shOll/(!

show

liD

traces

of

dirt

or

other debris.

If the rag is dirty. the

cylinder is not

clean enough

and

mllst

be

rewashed.

After the

cylinder is thoroughly clean,

dry

and

lubricate the cylinder walf with

clellll engine

oil

10

prel'em Ihe cylinder

/iller from iormillg

rlI

st.

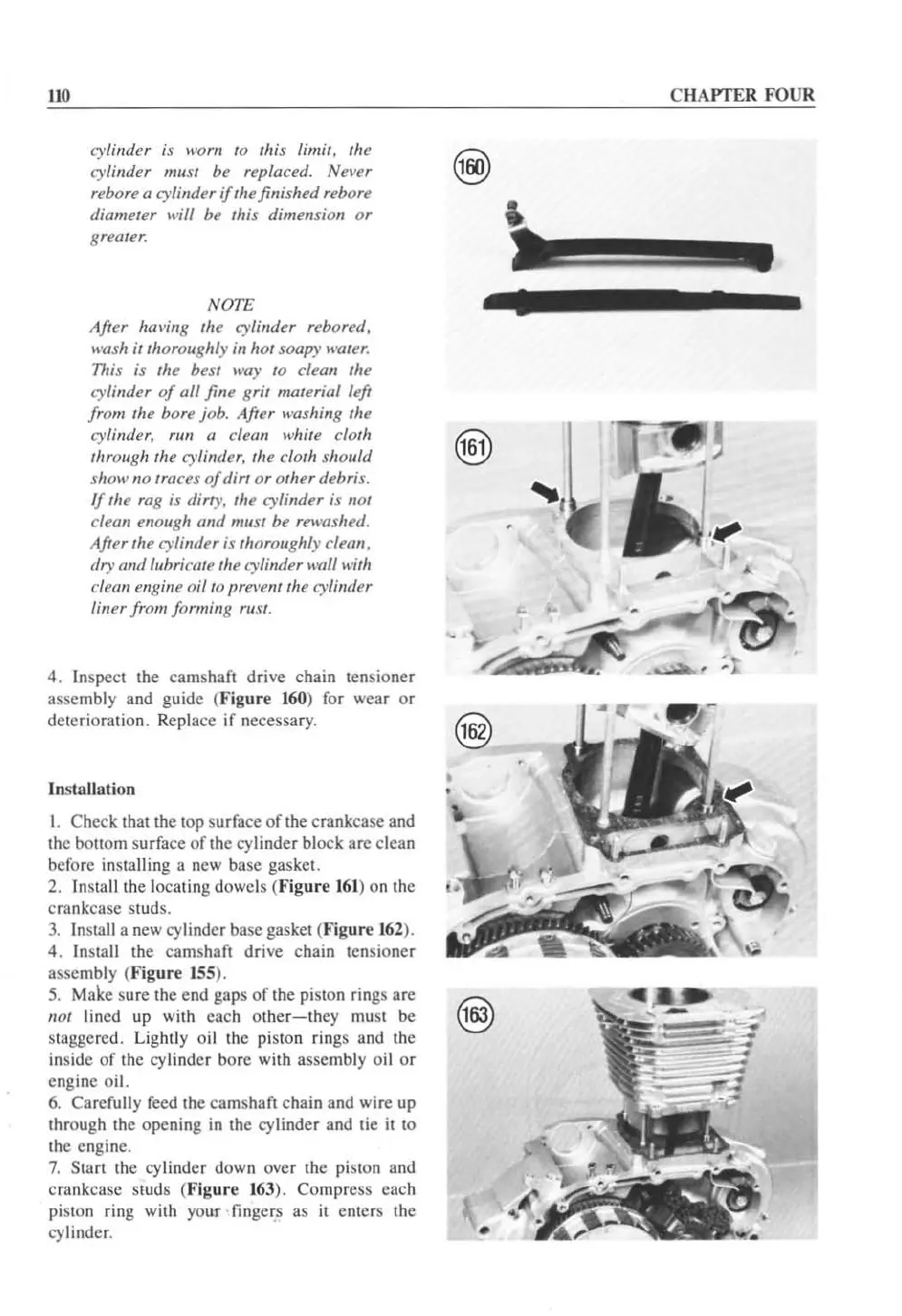

4. Inspect the camshaft drive chain (ensioner

assembly and guide

(F

igur

e 160)

fo

r wear

or

deterioration. Replace if necessary.

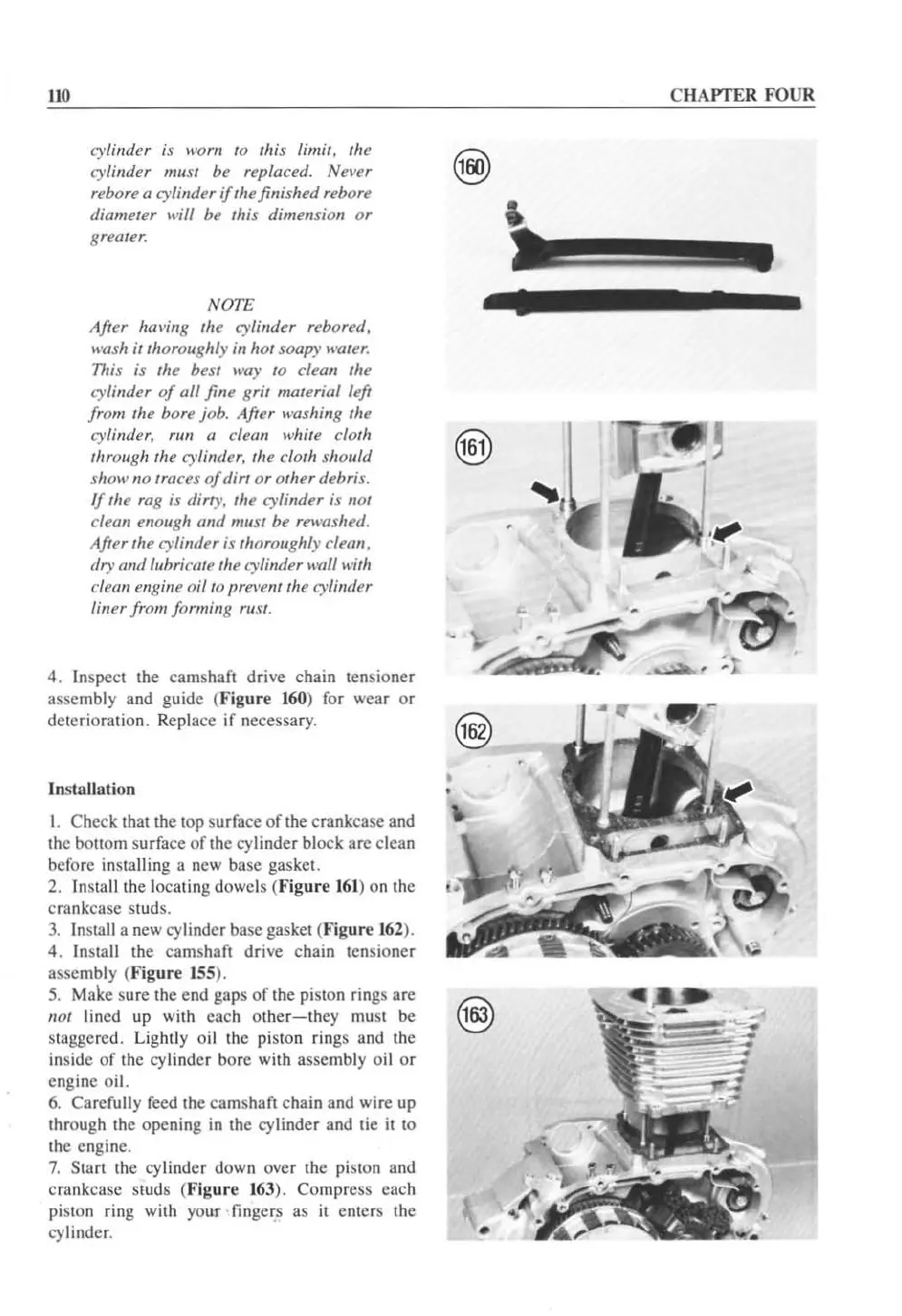

Installation

I.

Check that the top surface

of

the crankcase and

the bottom surface

of

the

cy

linder block are clean

before

installi

ng

a new base gasket.

2.

Insta

ll

the locating dowels (Figure

161

) on the

crankcase studs.

3.

Ins

tall

a

new

cylinder base gasket

(F

igure

16

2).

4.

Install the camshaft drive chain tensioner

asse

mb

ly (

Fi

g

ur

e

155

).

@)

@

•

5.

Make sure the end gaps

of

the piston rings are

/lot

lined up with each o

th

er-

th

ey

must

be

@

staggered. Lightly oil the piston rings and the

ins

ide

of

the

cy

linder bore with assembly oil

or

engine oil.

6.

Carefully feed the camshaft chain and wire up

through the openi

ng

in

the cylinder and tie it

to

the engi

ne.

7.

Start the cylinder down over the piston and

crankcase studs (

Figure

163

). Compress each

piston ring with your fingers as

it enters the

cy

linder. -

CHAPTER FOUR

~

,

,,

'h

,

•

•

_

~~

:1:

Loading...

Loading...