234

wi

res. Also check

Ihe

bulb sockel for

corrosion; replace as necessary.

4.

Pu

sh

th

e lamp socket/electrical wire assembly

back into the housing. Make sure

it

is completely

scated to prevent the entry

of

water and moisture.

5.

Install the fuel lank as desc

ri

bed in Chapter

Twelve.

Ignition Switch

Continuity Test

SW

ITCH

ES

The ignition switch

ca

nnot

be

separated. If either

t

he

electrical or mechanical portions

of

l

he

switch

become defective.

th

e entire switch assembly must

be

replaced.

I. Remo

ve

the scat as described in Chapler

Twelve.

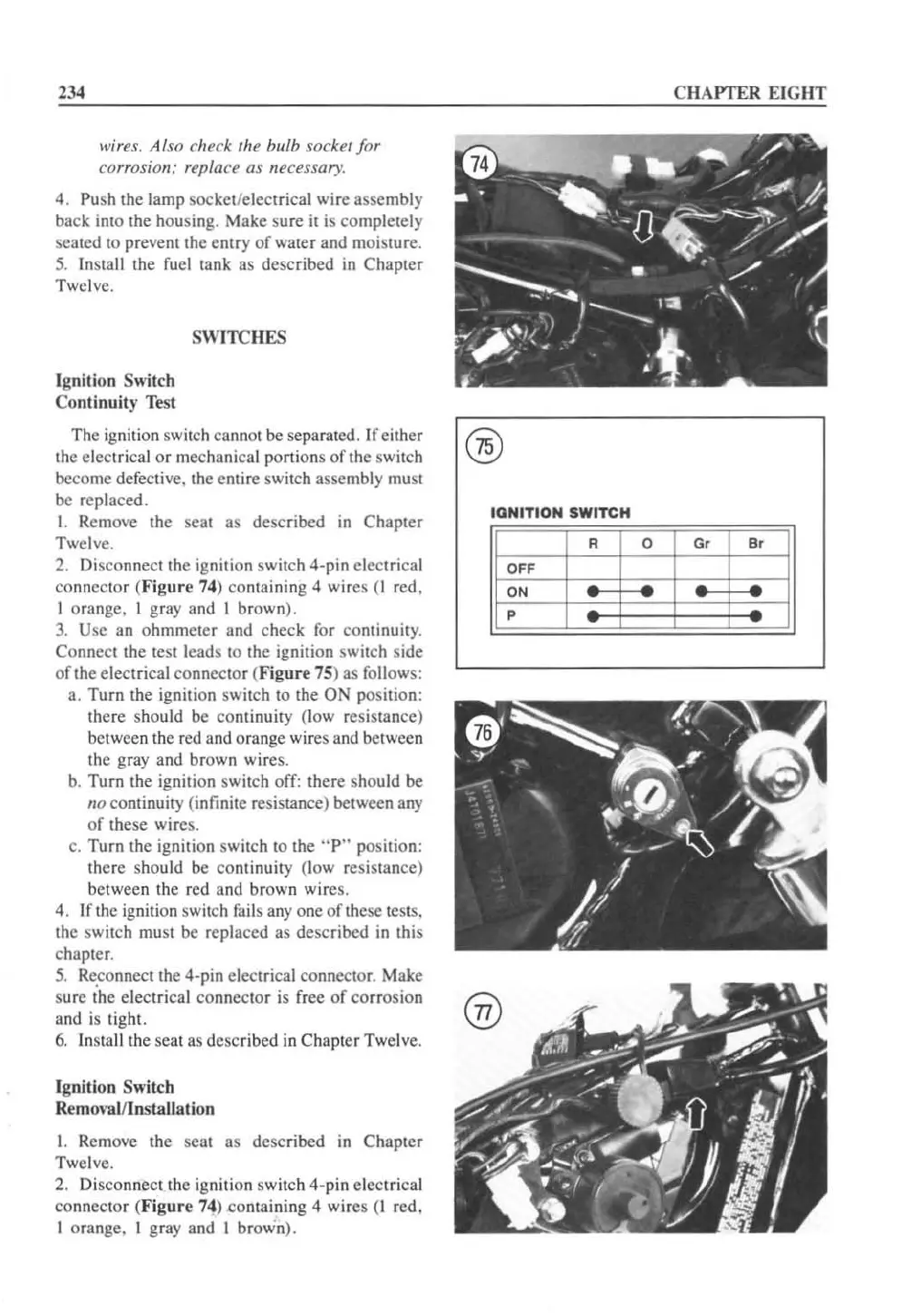

2.

Di

sconn

ecllhe

ignition switch 4-pin electrical

connector (

Figur

e

74

) con

ta

in

ing

4 wires

(I

red.

I orange. I

gray

and 1

brown),

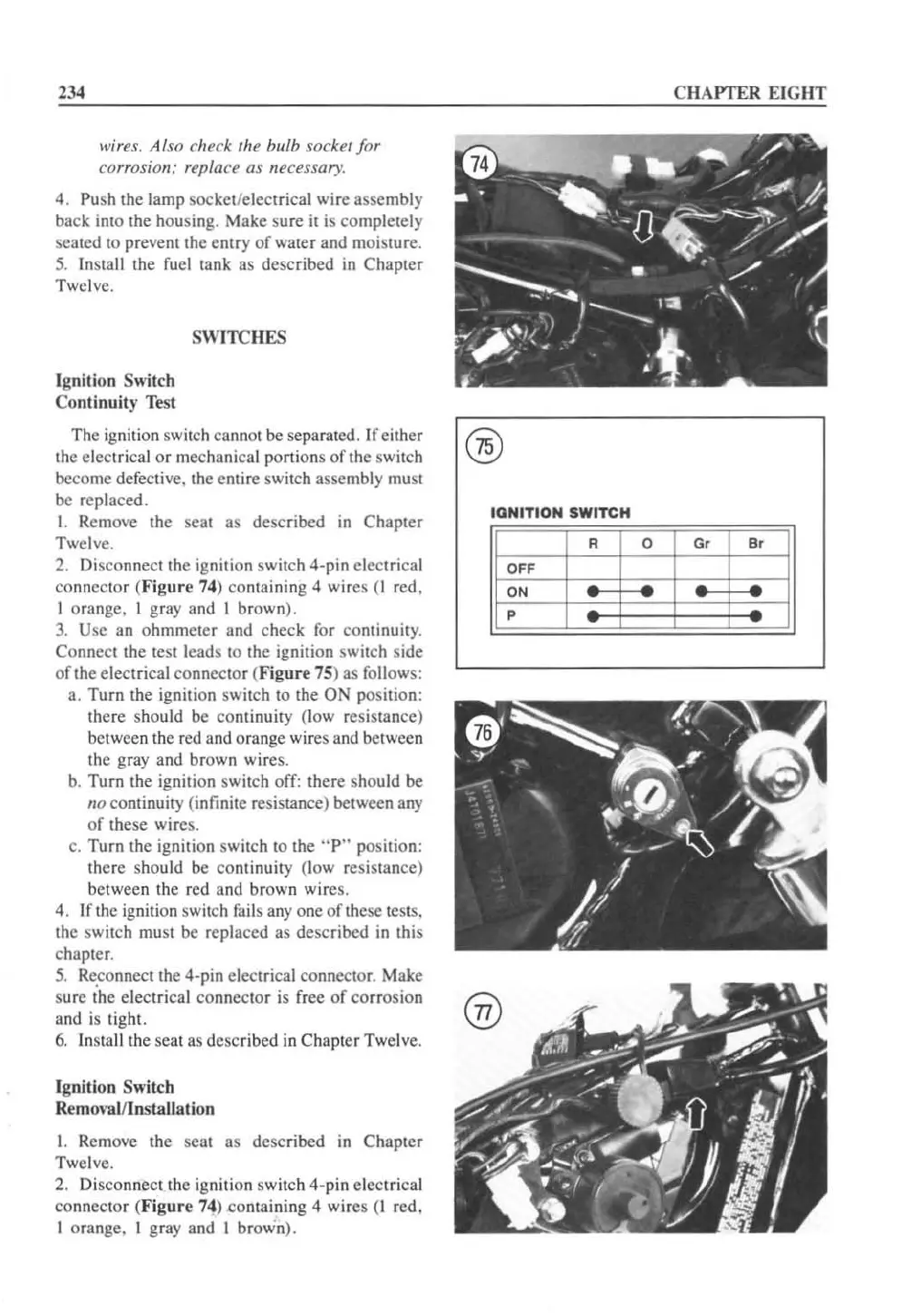

3.

Usc

an

ohmmeter

and

check for continuity.

Connect the test leads to the ignition switch side

of the electrical connector (

Figur

e 75) as

fo

ll

ows:

a.

Tu

rn the ignition switch to the ON position:

there should be continuity (low resistance)

between the red and orange wires and between

the gray and brown wires.

b.

Tu

rn the igni tion switch off: there should be

flO

co

ntinuity

(i

nfinite resistance) between any

of

these wires.

c.

Tu

rn the ignition switch to the

"P"

position:

there should be continuity (low resistance)

between the red

li

nd

br

own wire

s.

4. If the ignition switch

fai

ls

anyone

of

th

ese

te

sts.

the switch mu

st

be replaced as described

in

this

chapter.

5.

Re

,con

nC<:t

the 4-pin electrical co

nn

ector. Make

sure the electrical connector

is

free

of

co

rrosion

and is

ti

ght.

6.

Install the seat

liS

described in Chapt

er

Twel

ve.

Ignition Switch

Removallinstallal.ion

I. Remove the seat as described

in

Chapter

Twel

ve.

2. Disco

nn

ect the ignition

sw

it

ch 4-pin electrical

co

nn

ector (

Figure

74) containing 4

wi

res (I re

d.

I orange. I gr

ay

and I brown).

CHAPTER EIGHT

IQNITION

SWITCH

R 0

G,

B,

OFF

ON

P

®

Loading...

Loading...