1B-10 Emission Control Devices:

Installation

Install the HO2 sensor in the reverse order of removal.

Pay attention to the following points:

CAUTION

!

Do not apply oil or other materials to the

sensor air hole.

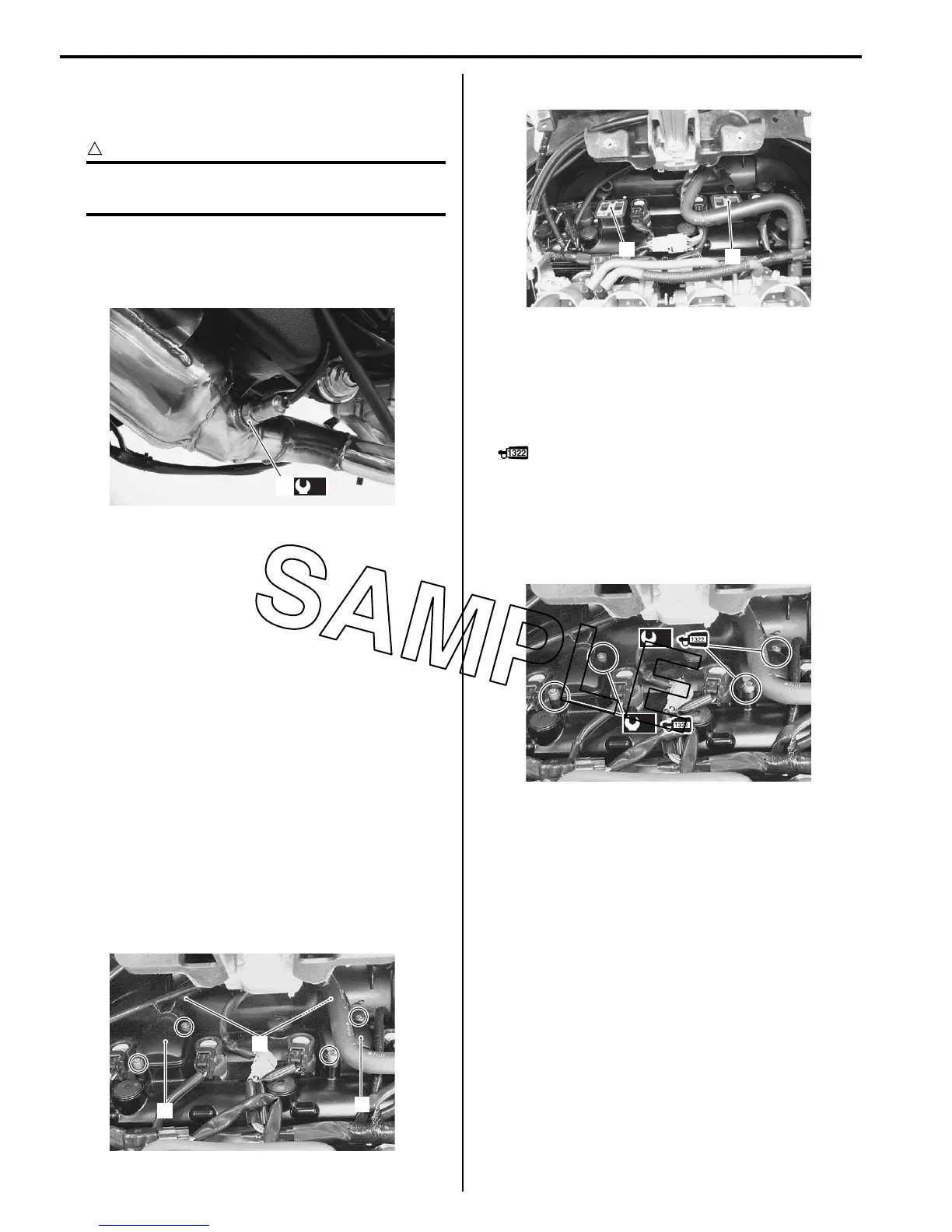

• Tighten the HO2 sensor (1) to the specified torque.

Tightening torque

HO2 sensor (a): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

• Route the HO2 sensor lead wire properly. Refer to

“Wiring Harness Routing Diagram in Section 9A

(Page 9A-5)”.

Heated Oxygen Sensor (HO2S) Inspection

B823H11206002

Refer to “DTC “C44” (P0130/P0135): HO2 Sensor

(HO2S) Circuit Malfunction in Section 1A (Page 1A-

104)”.

PAIR Reed Valve Removal and Installation

B823H11206003

Removal

1) Lift and support the fuel tank. Refer to “Fuel Tank

Removal and Installation in Section 1G (Page 1G-

10)”.

2) Remove the air cleaner box. Refer to “Air Cleaner

Box Removal and Installation in Section 1D

(Page 1D-6)”.

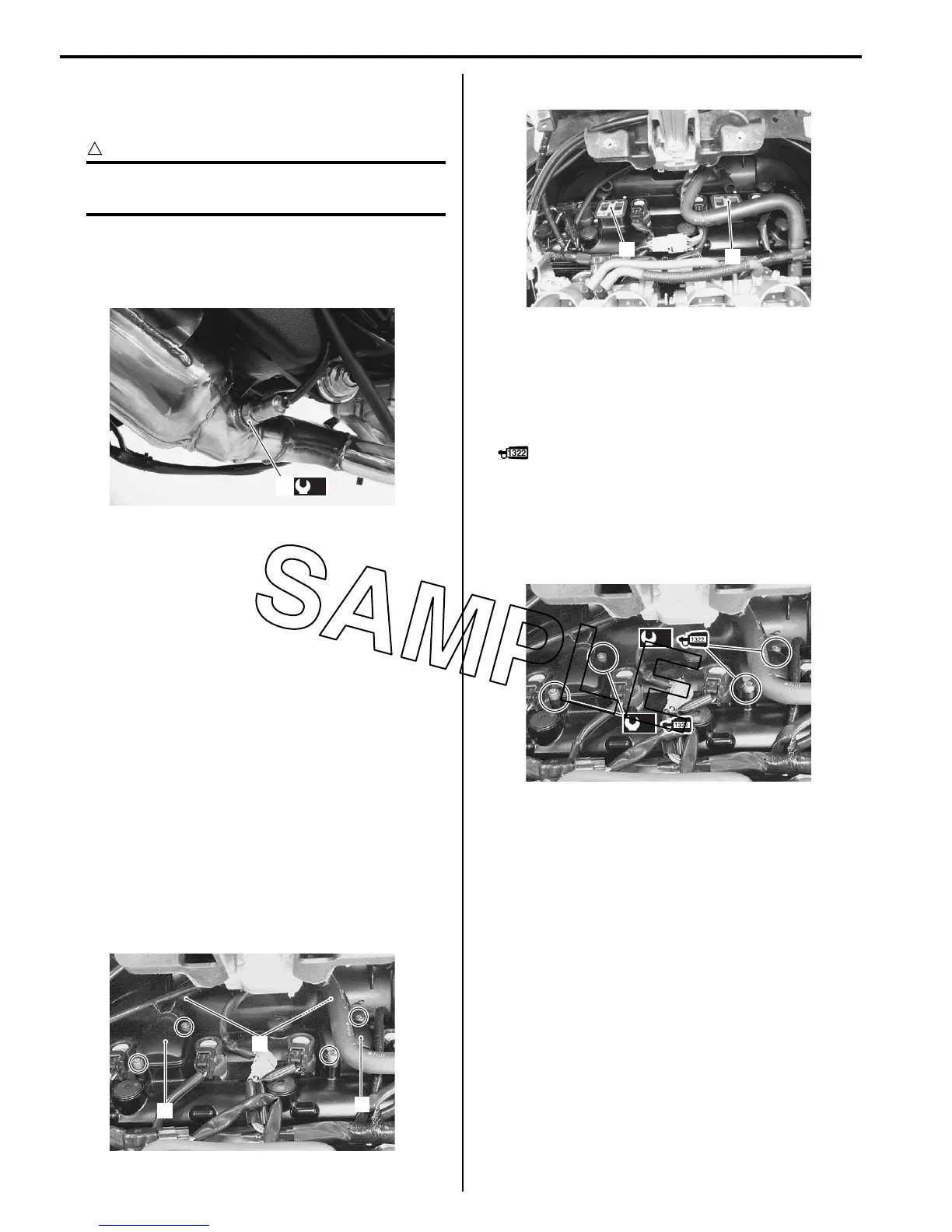

3) Disconnect the PAIR hoses (1) and remove the PAIR

reed valve covers (2).

4) Remove the PAIR reed valves (3).

Installation

Install the PAIR reed valve in the reverse order of

removal. Pay attention to the following points:

• Apply thread lock to the bolts and tighten them to the

specified torque.

: Thread lock cement 99000–32110

(THREAD LOCK CEMENT SUPER 1322 or

equivalent)

Tightening torque

PAIR reed valve cover bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

(a)

1

I823H1120007-03

1

2

2

I823H1120008-07

3

3

I823H1120009-02

(a)

(a)

I823H1120010-01

Loading...

Loading...