Engine Mechanical: 1D-60

Cylinder Inspection

B823H11406031

Refer to “Engine Top Side Disassembly (Page 1D-28)”.

Refer to “Engine Top Side Assembly (Page 1D-32)”.

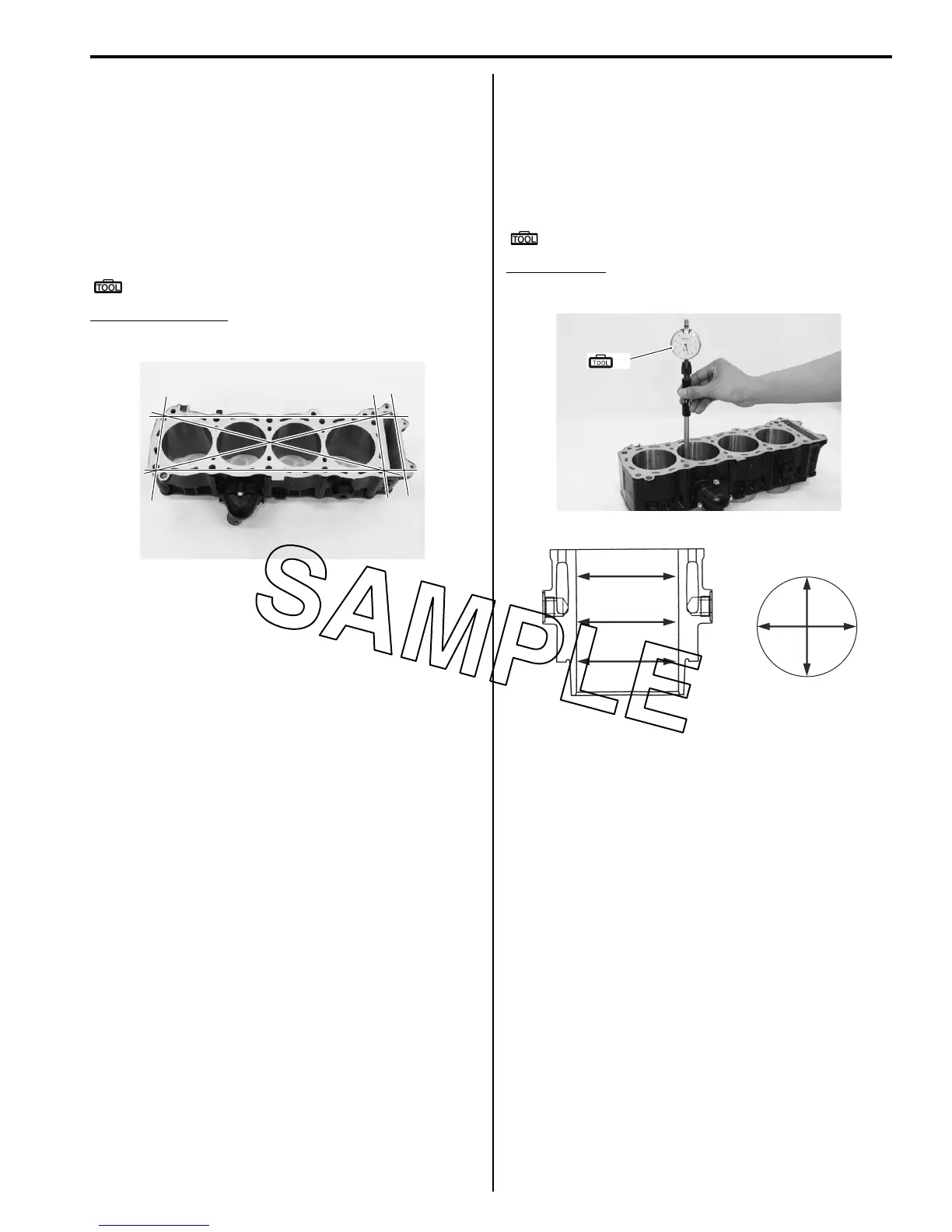

Cylinder Distortion

Check the gasket surface of the cylinder for distortion.

Use a straightedge and thickness gauge. Take clearance

readings at several places. If any reading exceeds the

service limit, replace the cylinder.

Special tool

: 09900–20803 (Thickness gauge)

Cylinder distortion

Service limit: 0.20 mm (0.008 in)

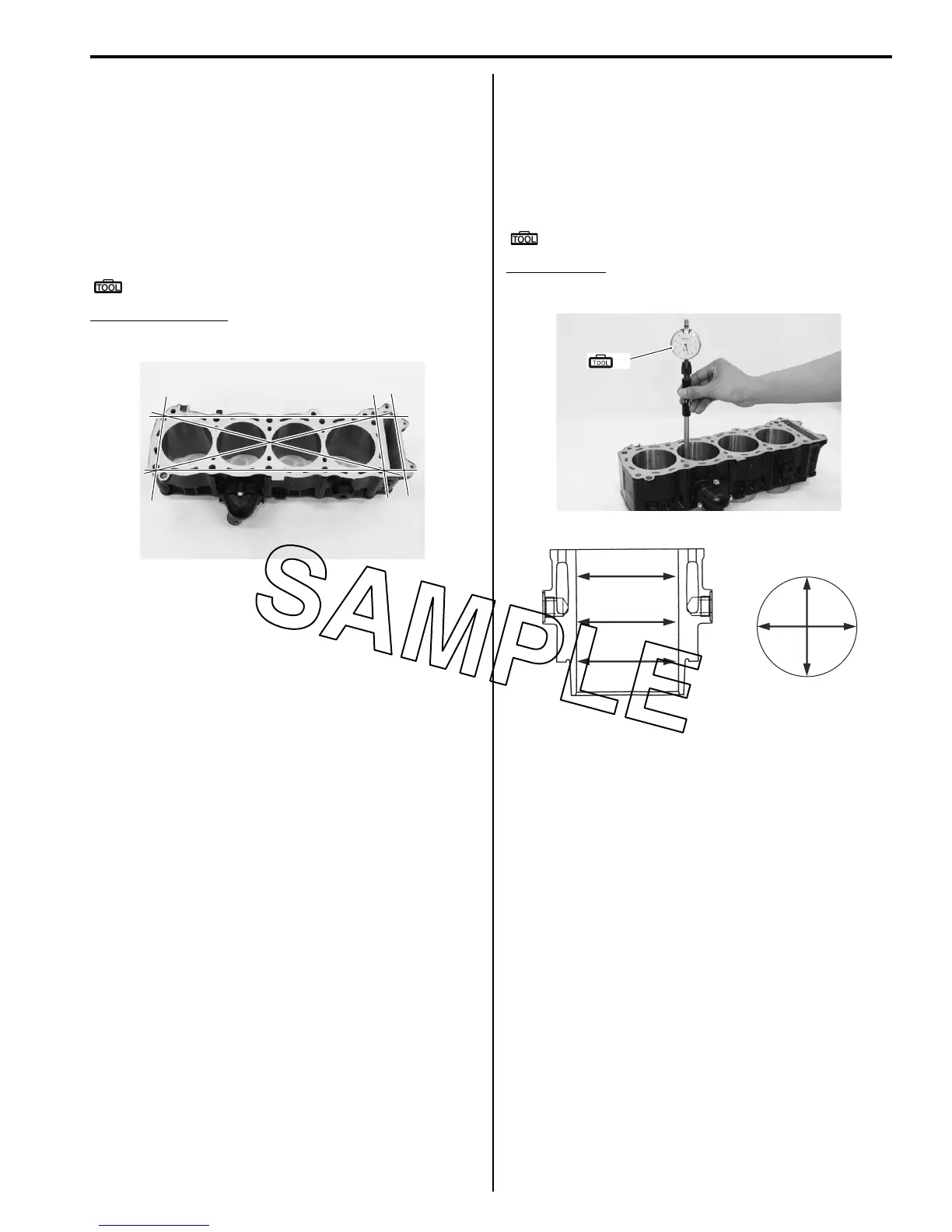

Cylinder Bore

Measure the cylinder bore diameter at six places. If any

one of the measurements exceed the limit, overhaul the

cylinder and replace the piston with an oversize piston.

The remaining cylinders must also be rebored

accordingly; otherwise, the imbalance might cause

excessive vibration.

Special tool

(A): 09900–20530 (Cylinder gauge set)

Cylinder bore

Standard: 81.000 – 81.015 mm (3.1890 – 3.1896 in)

Piston-to-cylinder Clearance

Refer to “Piston and Piston Ring Inspection (Page 1D-

62)”.

I823H1140402-01

(A)

I823H1140403-01

I823H1140146-02

Loading...

Loading...