1D-53 Engine Mechanical:

• Be sure that the rounded lip “K” of the cotter fits

snugly into the groove “L” in the stem end.

• Install the other valves and springs in the same

manner as described previously.

• Install the tappet shims and the tappets to their

original positions.

NOTE

• Apply engine oil to the stem end, shim and

tappet before fitting them.

• When seating the tappet shim, be sure the

figure printed surface faces the tappet.

Cylinder Head Related Parts Inspection

B823H11406027

Refer to “Cylinder Head Disassembly and Assembly

(Page 1D-48)”.

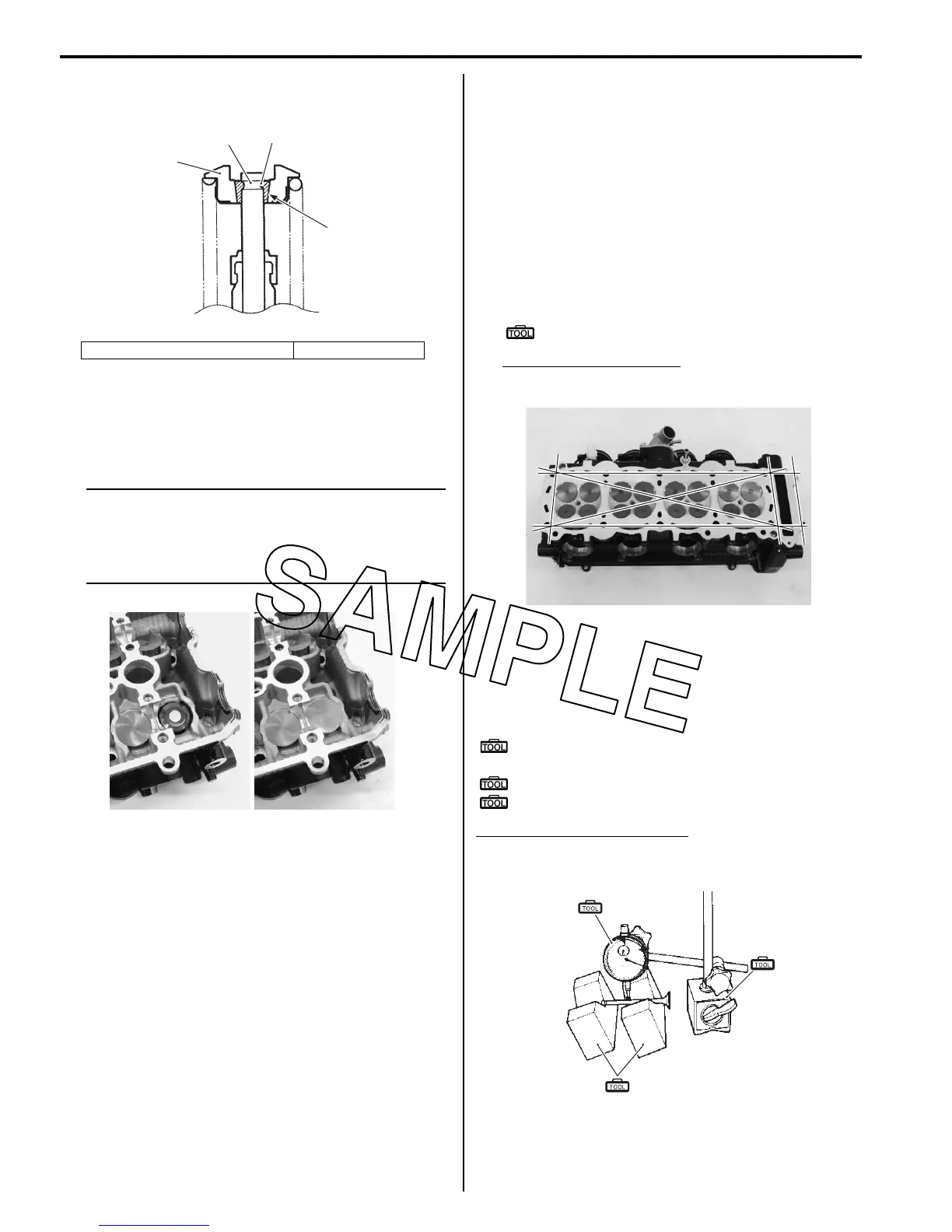

Cylinder Head Distortion

1) Decarbonize the combustion chambers.

2) Check the gasket surface of the cylinder head for

distortion. Use a straightedge and thickness gauge.

Take clearance readings at several places. If

readings exceed the service limit, replace the

cylinder head.

Special tool

: 09900–20803 (Thickness gauge)

Cylinder head distortion

Service limit: 0.20 mm (0.008 in)

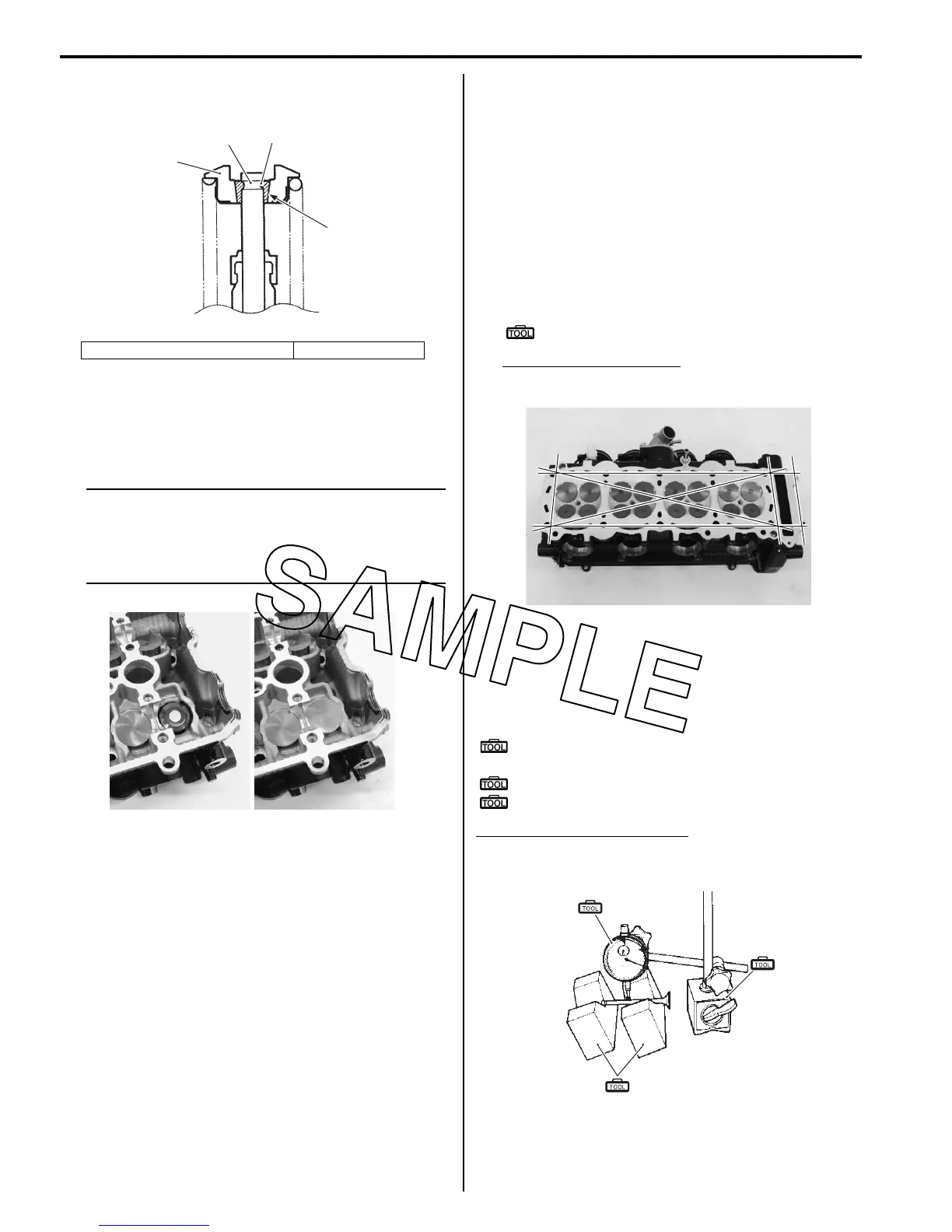

Valve Stem Runout

Support the valve using V-blocks, as shown in the figure,

and check its runout using the dial gauge. If the runout

exceeds the service limit, replace the valve.

Special tool

(A): 09900–20607 (Dial gauge (1/100 mm, 10

mm))

(B): 09900–20701 (Magnetic stand)

(C): 09900–21304 (V-block (100 mm))

Valve stem runout (IN. & EX.)

Service limit: 0.05 mm (0.002 in)

8. Valve spring retainer 9. Cotter

“K”

8

9

“L”

I823H1140127-04

I823H1140389-01

I823H1140390-01

(A)

(C)

(B)

I649G1140231-03

Loading...

Loading...