Engine Lubrication System: 1E-11

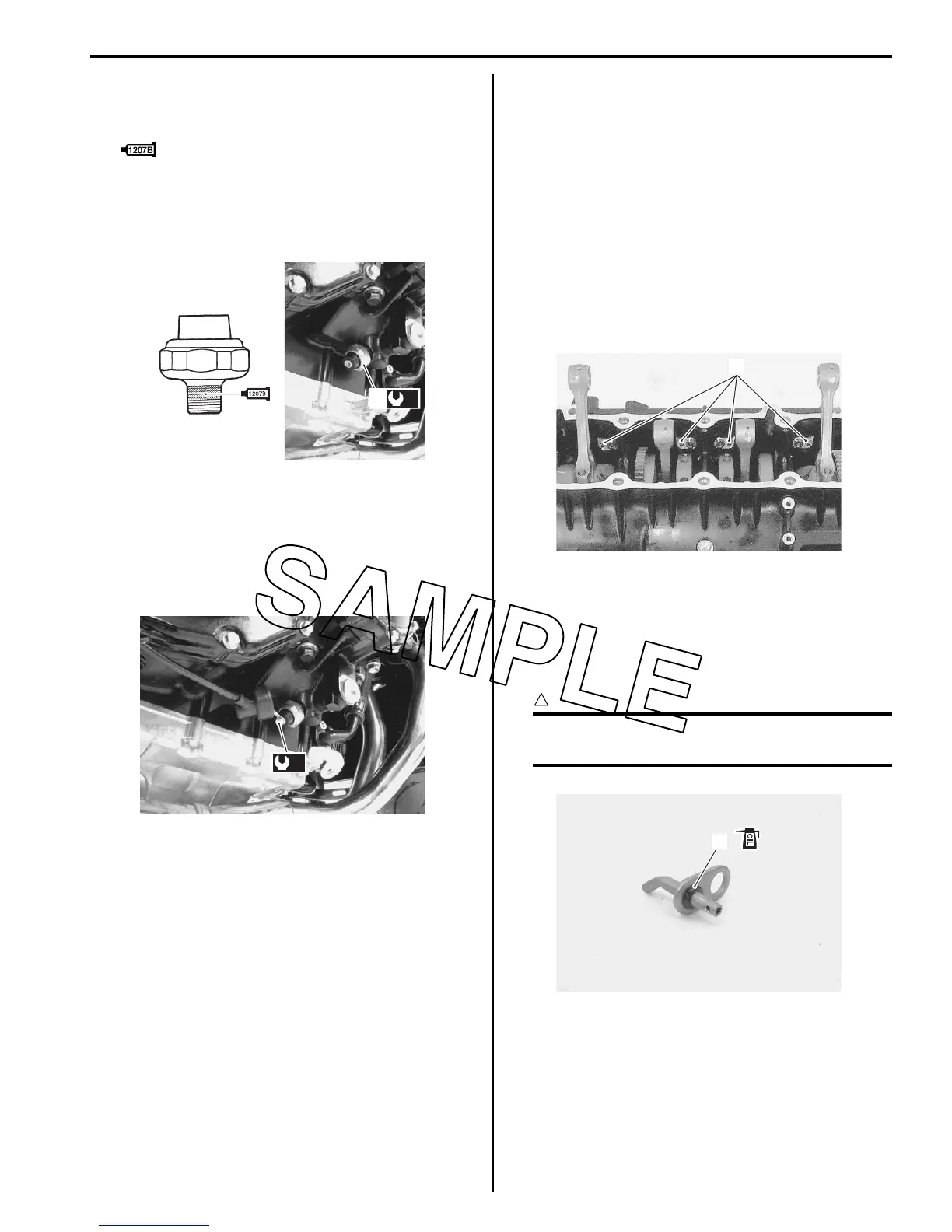

Installation

1) Install the oil pressure switch (1), apply a bond lightly

to its thread and tighten it to the specified torque.

: Sealant 99000–31140 (SUZUKI Bond

1207B or equivalent)

Tightening torque

Oil pressure switch (a): 14 N·m (1.4 kgf-m, 10.0

lb-ft)

2) Connect the oil pressure switch lead wire securely.

Refer to “Wiring Harness Routing Diagram in

Section 9A (Page 9A-5)”.

Tightening torque

Oil pressure switch lead wire bolt (b): 1.5 N·m (

0.15 kgf-m, 1.1 lb-ft)

3) Pour engine oil. Refer to “Engine Oil and Filter

Replacement in Section 0B (Page 0B-10)”.

4) Install the removed parts.

Oil Pressure Switch Inspection

B823H11506007

Refer to “Oil Pressure Indicator Inspection in Section 9C

(Page 9C-8)”.

Oil Jet / Oil Gallery Jet Removal and Installation

B823H11506008

Oil Jet (For Pistons)

Removal

1) Remove the engine assembly. Refer to “Engine

Assembly Removal in Section 1D (Page 1D-19)”.

2) Remove the Cylinder. Refer to “Engine Top Side

Disassembly in Section 1D (Page 1D-28)”.

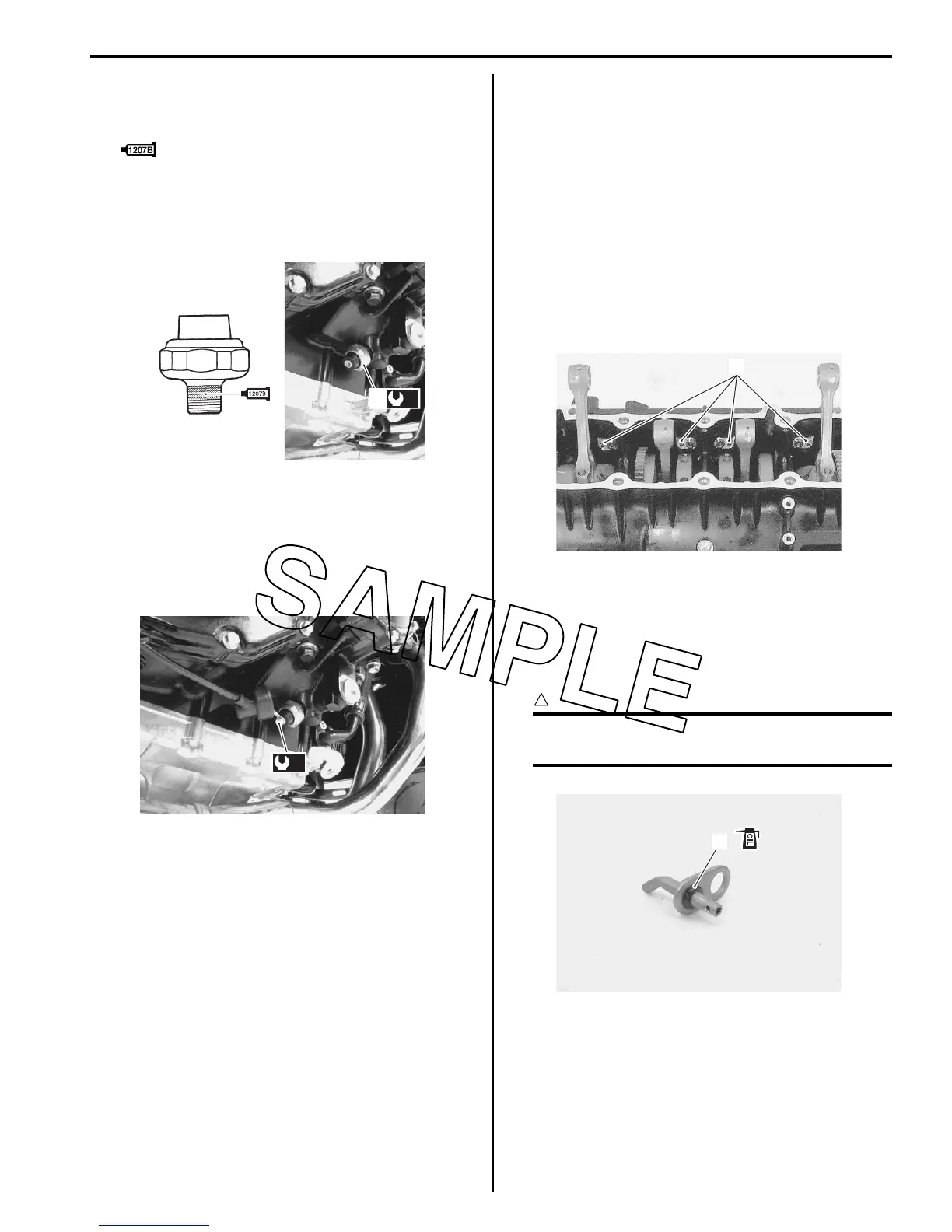

3) Remove the piston cooling oil jets (1).

Installation

Installation is in the reverse order of removal. Pay

attention to the following points:

• Fit the new O-ring (1) to each piston cooling oil jet and

apply engine oil to them.

CAUTION

!

Use the new O-rings to prevent oil pressure

leakage.

(a)

1

I823H1150046-02

(b)

I823H1150016-01

1

I823H1150032-02

1

I823H1150033-01

Loading...

Loading...