Engine General Information and Diagnosis: 1A-109

DTC P0335: Crankshaft Position (CKP) Sensor “A” Circuit

S7RS0B1104041

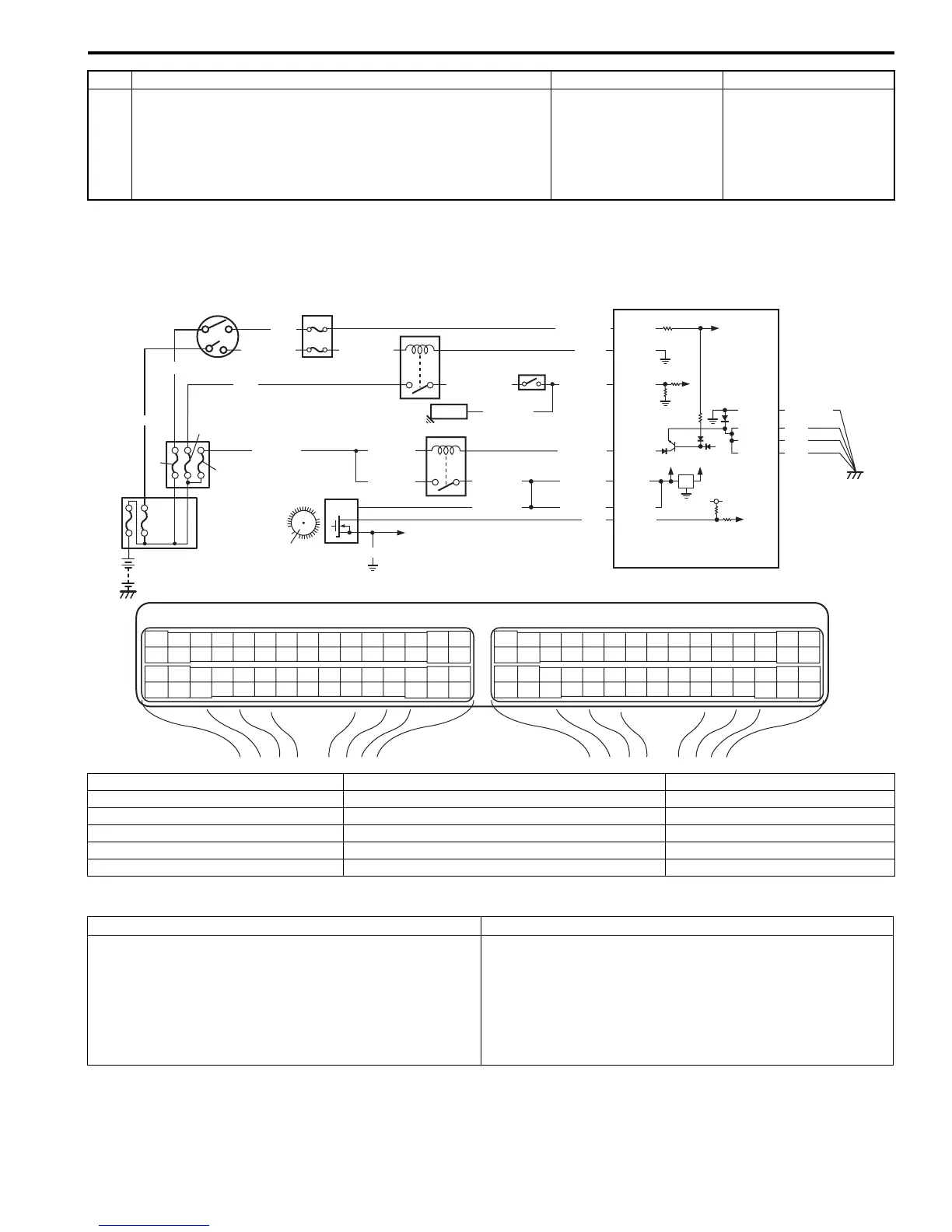

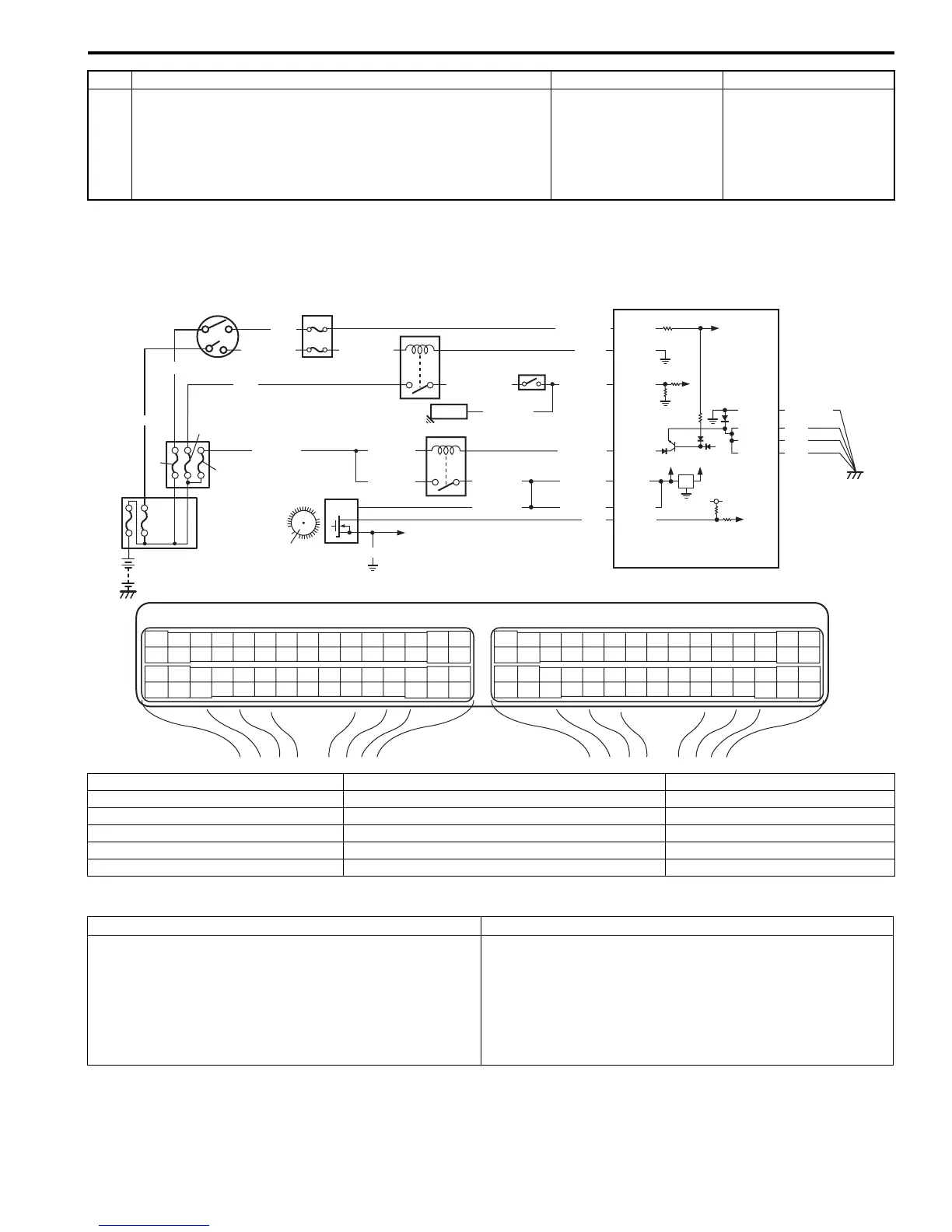

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Crank engine for 3 – 5 sec.

4) Check DTC.

7 Knock sensor circuit for high resistance check

1) Turn OFF ignition switch, measure resistance between

“C37-56” terminal of ECM connector and “RED” wire

terminal of knock sensor harness connector.

Is resistance below 5

Ω

?

Faulty knock sensor. “RED” wire is high

resistance circuit.

Step Action Yes No

E23 C37

34

1819

5671011

1720

47 46495051

2122

52

1625

9

24

14

29

5557 54 53

59

60 58

2

262728

15

30

56 48

32 31343536374042 39 38

44

45 43 41 33

11213

23

834

1819

5671011

1720

47 46495051

2122

52

1625

9

24

14

29

5557 54 53

59

60 58

2

262728

15

30

56 48

32 31343536374042 39 38

44

45 43 41 33

11213

23

8

12V

5V

BLK/RED

BLK/RED

BLK/YEL

BLK/YEL

BLK/YEL

BRN/WHT

5

9

4

13

3

C37-30

C37-15

C37-58

E23-31

BLK/ORN

BLK

BLK

BLK

10

BLK/RED

BLK/RED

E23-16

E23-60

E23-1

BLK/ORN

1

15

C37-21

5V

7

RED/WHT

GRN/WHT

GRN

RED

BLK/WHT

YEL/GRN

YEL/GRN

WHT

[A]: YEL

[B]: YEL/GRN

6

8

12

11

14

PNK

2

WHT

WHT/BLU

C37-48

E23-30

E23-29

I6RS0C110016-01

[A]: For A/T model 5. Ignition switch 11. “ST MOT” fuse

[B]: For M/T model 6. Starting motor 12. “ST SIG” fuse

1. CKP sensor 7. Starting motor control relay 13. “IG COIL” fuse

2. Sensor plate on crankshaft 8. Transmission range switch (for A/T model) 14. “IG ACC” fuse

3. ECM 9. Main fuse box 15. To CMP sensor

4. Main relay 10. “FI” fuse

DTC detecting condition Trouble area

No CKP sensor signal for 2 sec. even if starting motor

signal is inputted at engine cranking.

(1 driving cycle detection logic)

• CKP sensor circuit open or short

• Sensor plate teeth damaged

• CKP sensor malfunction, foreign material being attached

or improper installation

•ECM

• Engine start signal circuit malfunction

Loading...

Loading...