1B-3 Aux. Emission Control Devices:

Vacuum Passage Inspection

S7RS0B1206003

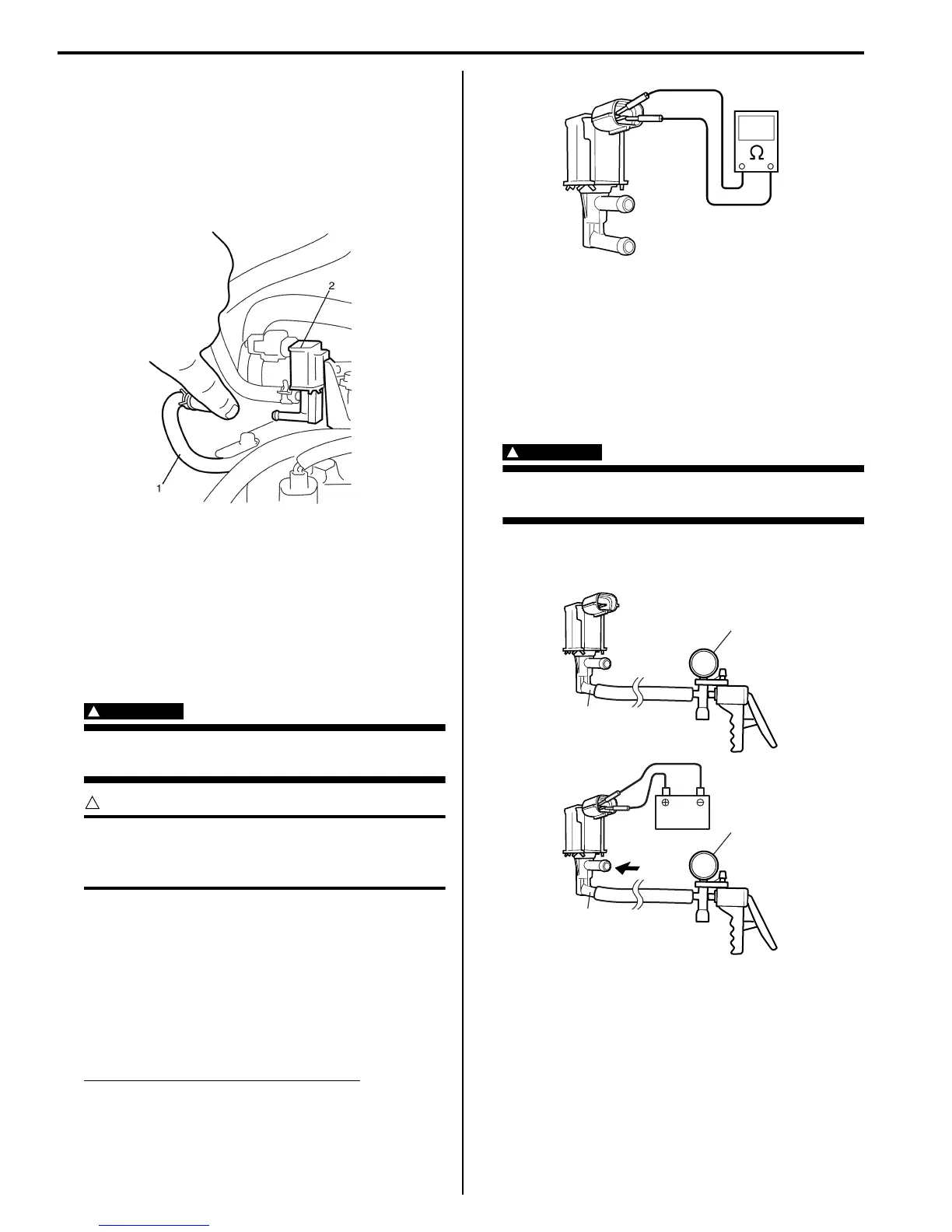

Start engine and run it at idle speed. Disconnect vacuum

hose (1) from EVAP canister purge valve (2). With finger

placed against disconnected hose, check that vacuum is

applied.

If it is not applied, clean vacuum passage by blowing

compressed air.

Vacuum Hose and Purge Valve Chamber

Inspection

S7RS0B1206004

Check hoses and purge valve chamber for connection,

leakage, clog and deterioration.

Replace as necessary.

EVAP Canister Purge Valve Inspection

S7RS0B1206005

WARNING

!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION

!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

1) With ignition switch turned OFF, disconnect coupler

and vacuum hoses from canister purge valve.

2) Remove EVAP canister purge valve from air cleaner

assembly.

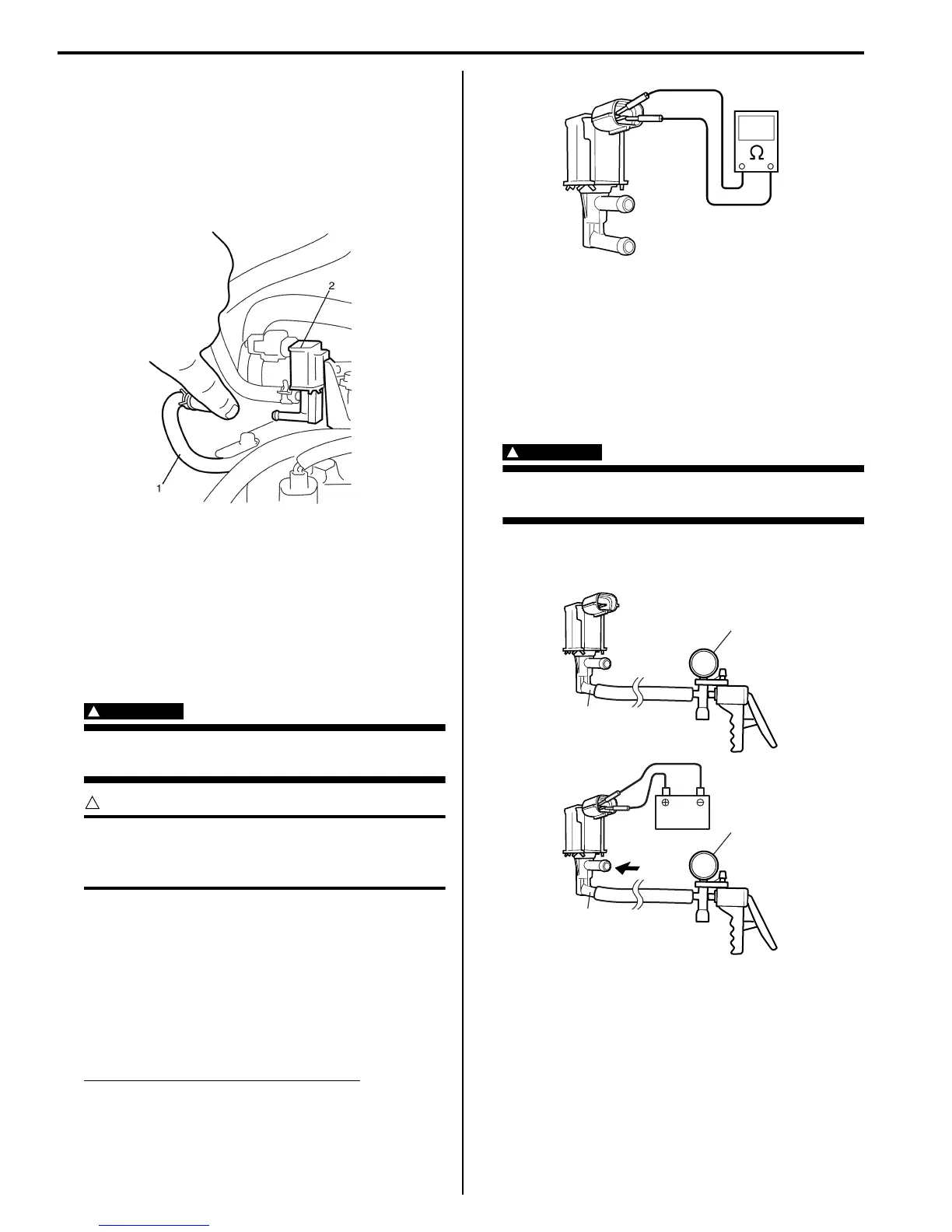

3) Check resistance between two terminals of EVAP

canister purge valve.

If resistance is not as specified, replace EVAP

canister purge valve.

EVAP canister purge valve resistance

30 – 34 Ω at 20 °C (68 °F)

4) With coupler disconnected, apply vacuum (–60 kPa

(–8.7 psi)) to pipe (1). If vacuum can be applied, go

to next step. If vacuum can not be applied, replace

EVAP canister purge valve.

5) In this state, connect 12 V-battery to EVAP canister

purge valve terminals. If vacuum can not be applied,

EVAP canister purge valve is in good condition.

If applied, replace EVAP canister purge valve.

WARNING

!

Do not suck the air through valve. Fuel vapor

inside valve is harmful.

Special tool

(A): 09917–47011

6) Install EVAP canister purge valve to air cleaner

assembly.

I3RM0A120006-01

I3RM0A120008-01

1

1

(A)

(A)

I3RB0A120007-01

Loading...

Loading...