Engine Electrical Devices: 1C-13

Without Using SUZUKI Scan Tool

1) Measure sensor voltage between “C37-23” terminal

of ECM connector and vehicle body ground referring

to “Inspection of ECM and Its Circuits in Section 1A”.

If check result is satisfactory, electric load current

sensor is in good condition.

If check result is not satisfactory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground

and output)

• Following charging system components

– Battery (refer to “Battery Inspection in Section

1J”)

– Generator (refer to “Generator Inspection in

Section 1J”)

– Generator output control circuit (refer to

“Generator Test (Undercharged Battery Check)

in Section 1J”)

– Generator field coil monitor circuit (refer to

“Generator Inspection in Section 1J”)

If electric load current sensor circuit and charging

system is in good condition, electric load current sensor

(1) is faulty.

Specifications

Tightening Torque Specifications

S7RS0B1307001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

2. Main fuse box

2

1

I5RS0C130001-01

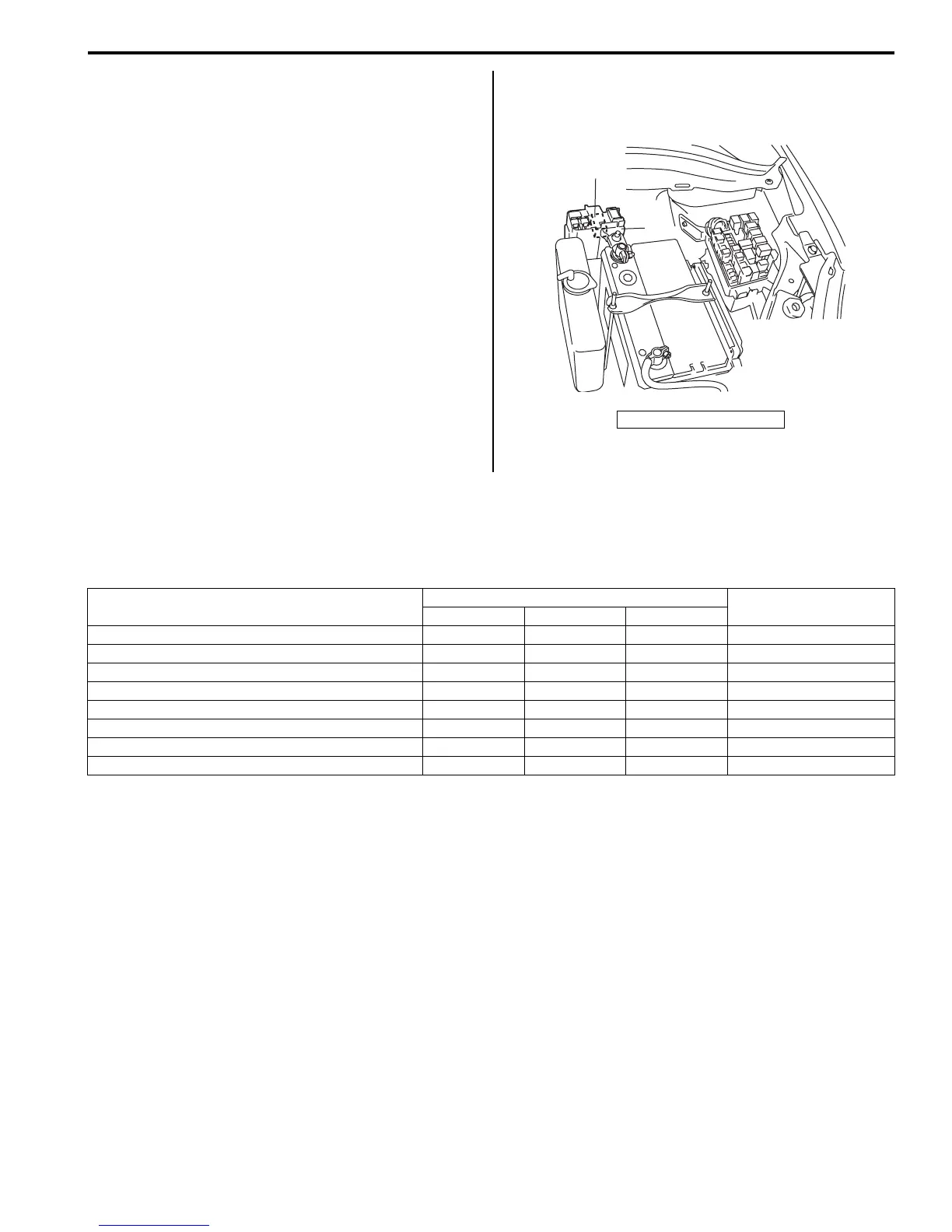

Fastening part

Tightening torque

Note

N⋅mkgf-mlb-ft

ECM mounting bolt 8 0.8 6.0 )

APP sensor assembly nut 5.5 0.55 4.0 )

ECT sensor 15 1.5 11.0 )

Heated oxygen sensor 45 4.5 32.5 )

CMP sensor bolt 10 1.0 7.5 )

CKP sensor bolt 10 1.0 7.5 )

Knock sensor 22 2.2 16.0 )

MAF and IAT sensor screw 1.5 0.15 1.1 )

Loading...

Loading...