Clutch: 5C-5

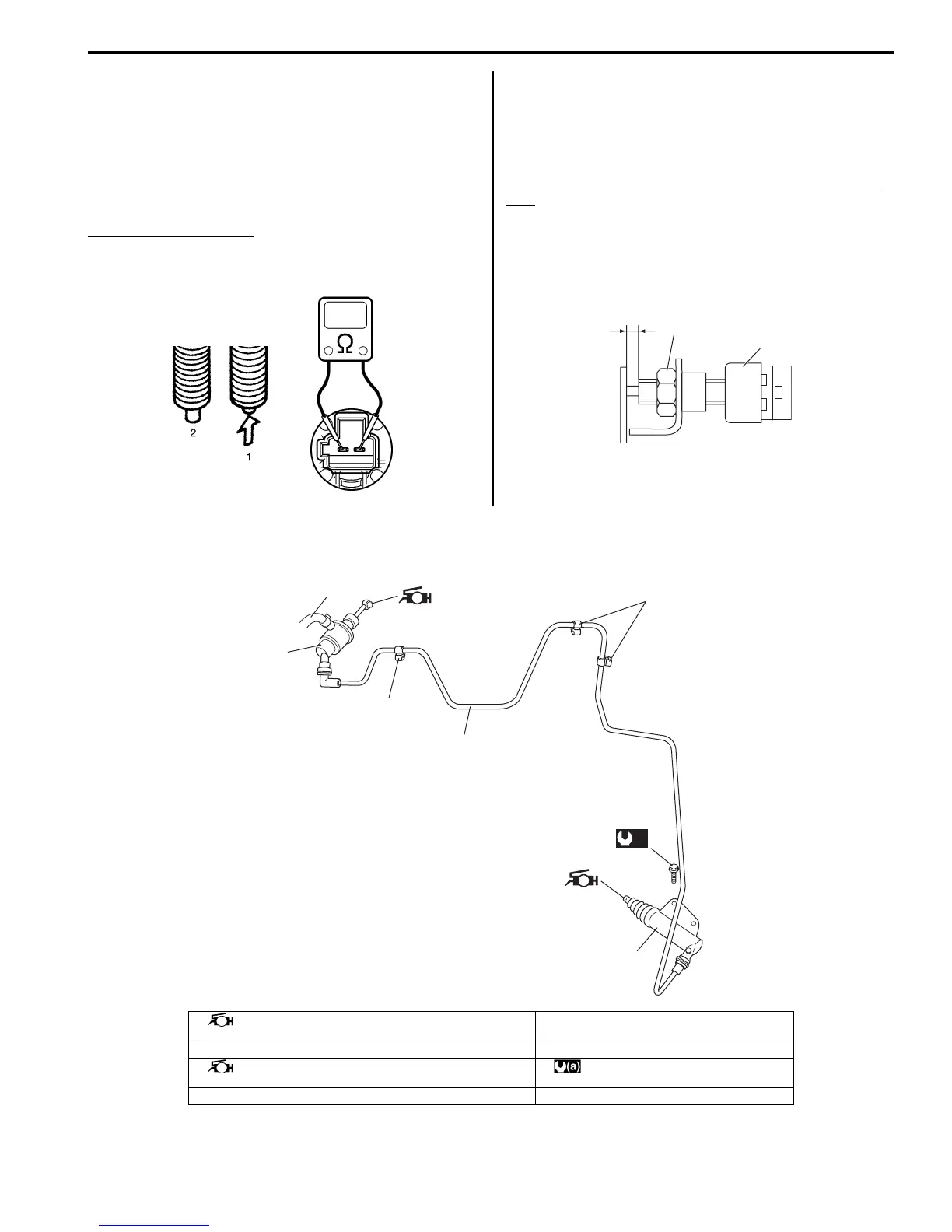

Clutch Pedal Position (CPP) Switch Inspection

and Adjustment

S7RS0B5306005

Inspection

Check for resistance between terminals under each

condition below. If check result is not satisfactory,

replace.

CPP switch resistance

When switch shaft is pushed (1): Continuity

When switch shaft is free (2): No continuity

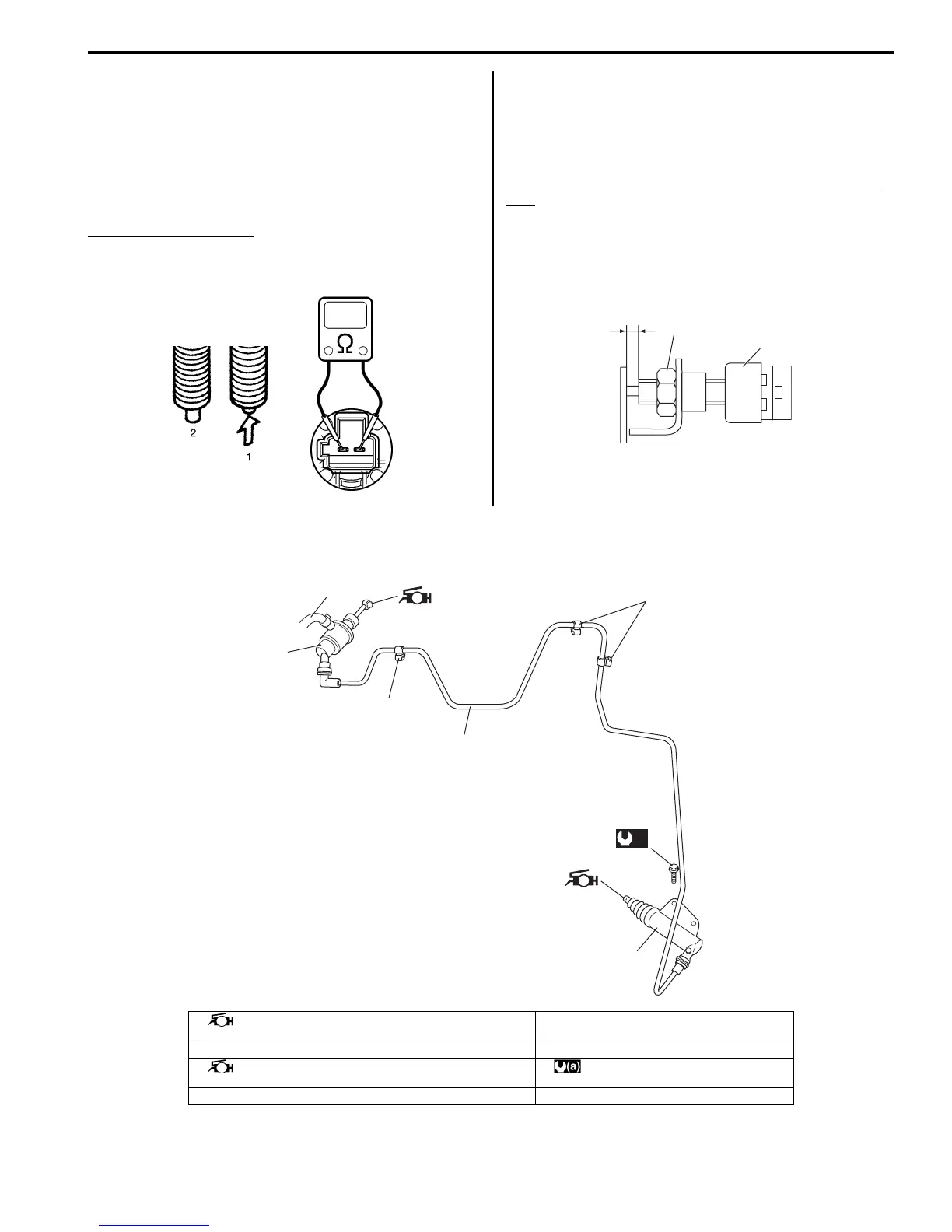

Adjustment

With clutch pedal depressed, adjust switch (1) position

so that clearance between end of thread and clutch

pedal arm is within specification, and then tighten lock

nut to specified torque.

Clearance between end of thread and clutch pedal

arm

“a”: 3.5 – 4.0 mm (0.14 – 0.16 in.)

Tightening torque

CPP switch lock nut (a): 7.5 N·m (0.75 kgf-m, 5.5 lb-

ft)

Clutch Fluid Pipe and Hose Components

S7RS0B5306006

I5JB0A530006-01

(a)

1

“a”

I6RS0C530002-01

6

1

5

2

5

4

(a)

3

I6RS0C530003-01

1. Master cylinder

: Apply grease 99000-25100 to push rod end.

5. Clamp

2. Pipe 6. Clutch reservoir hose

3. Operating cylinder

: Apply grease 99000-25100 to rod tip.

: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Operating cylinder bolt

Loading...

Loading...