4F-36 Electronic Stability Program:

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure

S7RS0B4604032

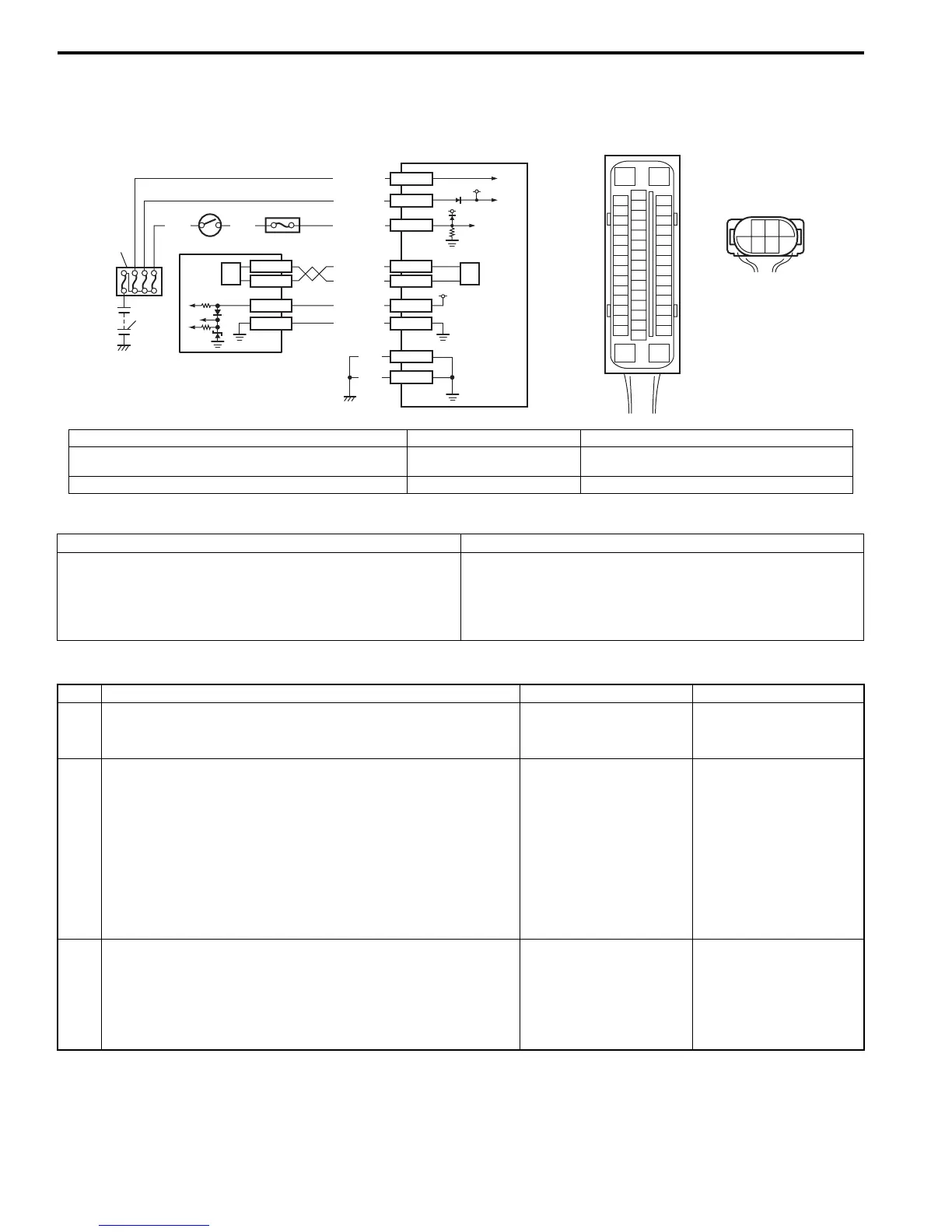

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]

E85

16

1

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[B]

E84

3

5

21

46

1

E85-16

E85-47

12V

12V

E85-32

E85-1

E85-35

GRNWHT

WHT/RED

WHT/BLU

E85-29

E85-25

E85-37

E85-31

E84-3

E84-5

RED/BLK

BLK

BLK

WHT/BLK

E84-2

E84-1

12V

GRN/BLK

BLU/RED

2

3

5

6

4

7

6

GRN/ORN

I7RS0B460009-01

[A]: ESP® control module connector (viewed from terminal side) 2. Main fuse box 5. Yaw rate / G sensor assembly

[B]: Yaw rate / G sensor assembly connector (viewed from

harness side)

3. Ignition switch 6. CAN driver

1. Battery 4. Junction block assembly 7. ESP® hydraulic unit / control module assembly

DTC Detecting Condition Trouble Area

• Power supply voltage of yaw rate / G sensor assembly

is too high when ignition switch OFF.

• Power supply voltage of yaw rate / G sensor assembly

is too low when ignition switch ON.

• Yaw rate / G sensor assembly power supply circuit

• ESP® control module power supply circuit

• Yaw rate / G sensor assembly

• ESP® control module

Step Action Yes No

1 Was “Electronic Stability Program Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 Check yaw rate / G sensor assembly ground circuit

1) Turn ignition switch to OFF position.

2) Disconnect yaw rate / G sensor assembly connector.

3) Check for proper connection to yaw rate / G sensor

assembly connector terminals at “E84-3” and “E84-5”.

4) If OK, then measure voltage between connector terminal

“E84-3” and vehicle body ground.

Is it 0 V?

Go to Step 3. Go to Step 4.

3 Check yaw rate / G sensor assembly power supply

circuit

1) Measure voltage between connector terminal “E84-3”

and “E84-5” with ignition switch turned ON.

Is it 10 – 14 V?

Substitute a known-

good yaw rate / G

sensor assembly and

recheck.

Go to Step 4.

Loading...

Loading...