Scanning

Original Feed, Exit Sequence

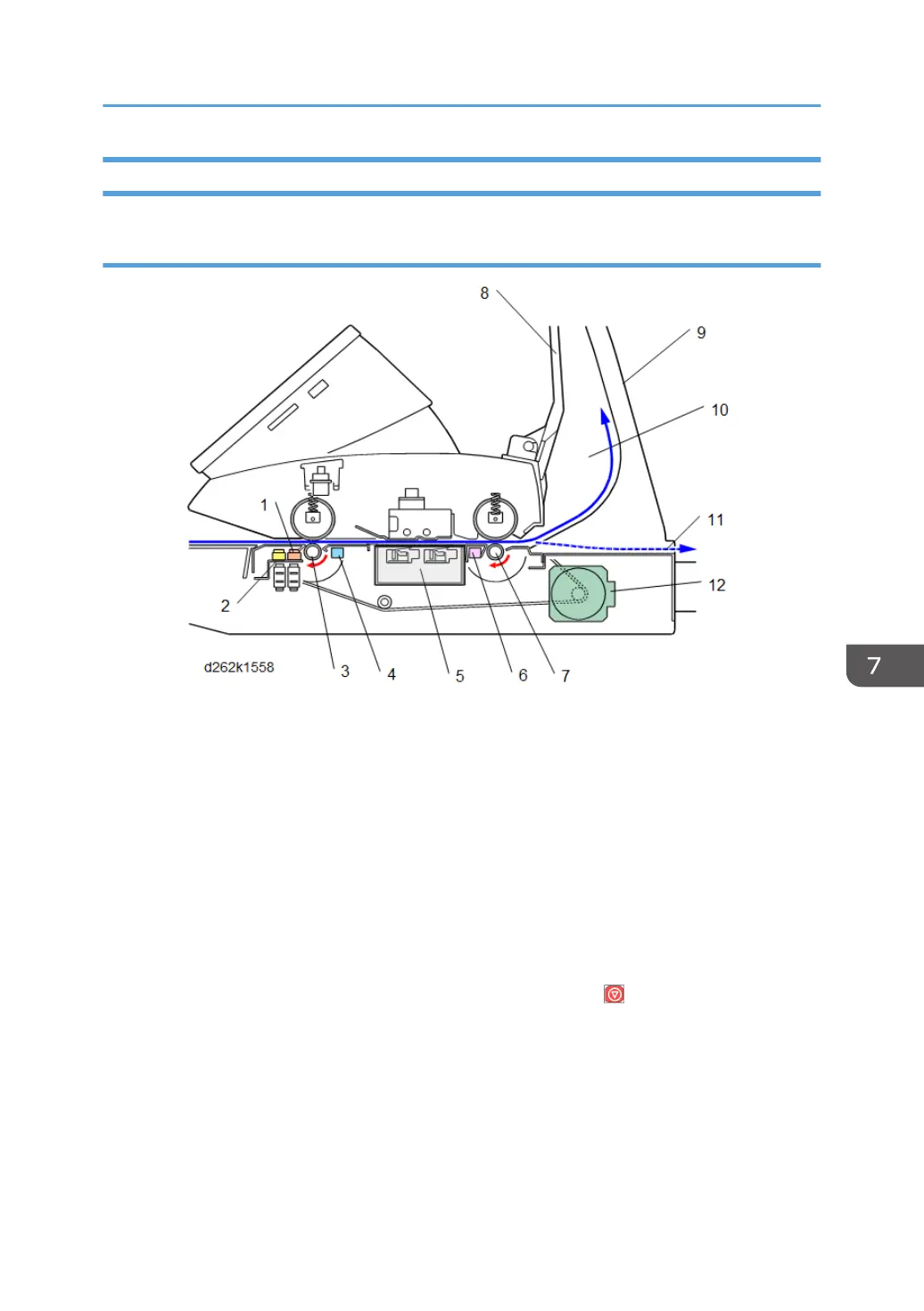

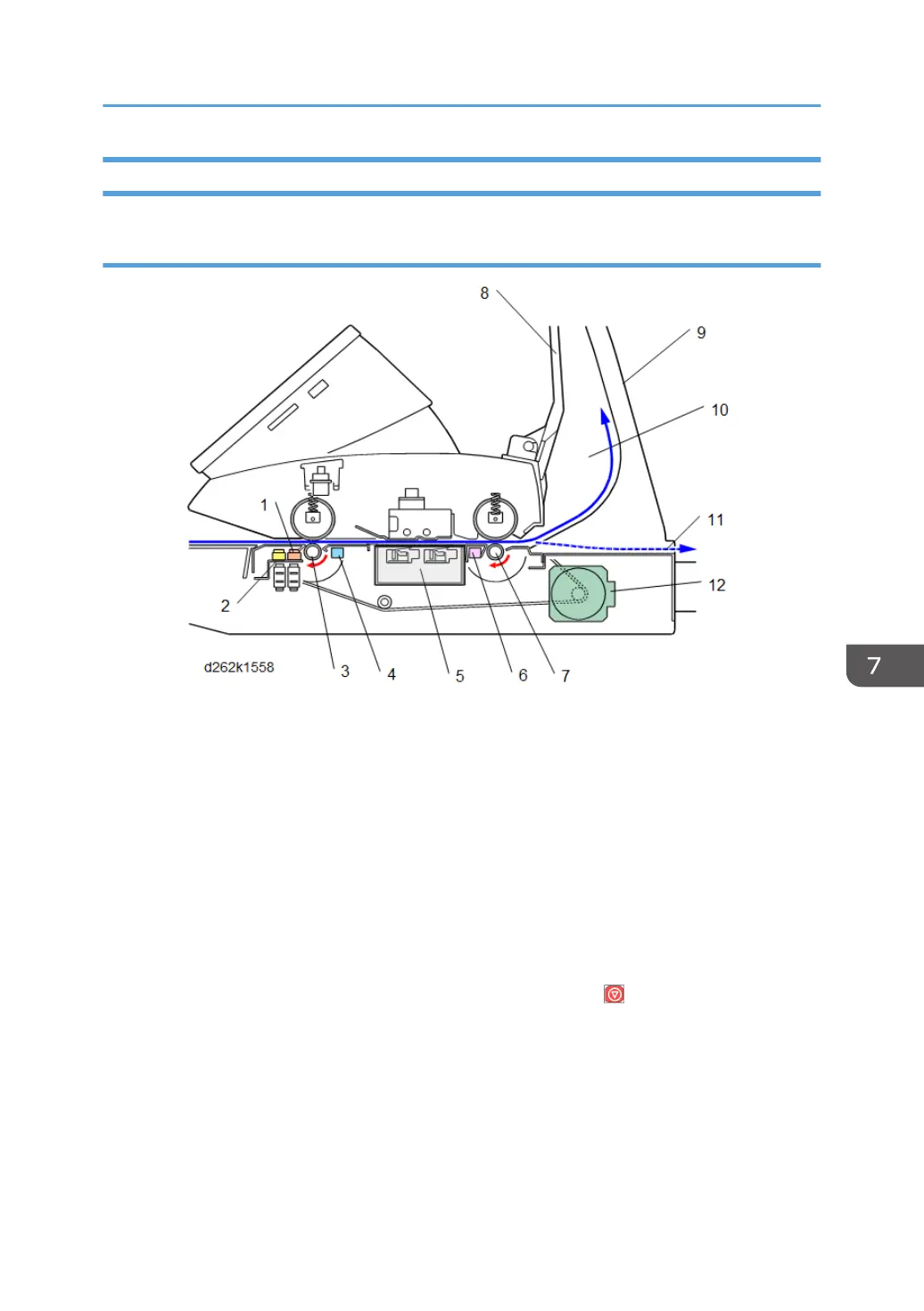

Only one original can be placed face-down on the original table.

• The original set sensor (1) detects the leading edge of the original and the original width sensors

(2) detect the width of the original.

• The original entrance roller (3) grabs the leading edge, feeds it a short distance and then stops for

1 sec. This is called Delay 1. This gives the operator time to set the paper again if it is not perfectly

straight.

• The original feed roller feeds the original to the original registration sensor (4).

• When the original registration sensor detects the leading edge of the original, the machine stops

original feed again for 1 sec. This is called Delay 2. This gives the operator another chance to

check that the original is straight.

• If the original is not straight, the user can push the original stop key ( ) on the right side of the

scanner unit, remove the original, and try again.

• The length of time for Delay 1 and Delay 2 to pause can be adjusted with User Tools > System

Settings > General Features > Original Feed Delay.

• The CIS (Contact Image Sensor) (5) scans the original from below.

• The original exit sensor (6) checks the timing of the passage between the leading and trailing

edges of the original to make sure that there is no jam.

Scanner Unit

777

Loading...

Loading...