• When the cutter (5) reaches the left side of the machine after cutting the paper, the cutter return

switch turns ON, and the cutter motor reverses to return the cutter to its home position on the right

side of the machine.

• This switch detection of the cutter shifts the paper transport fan into Duty 2 phase again.

This shift in the operation of the paper transport motor Duty 1 > Duty 2 > Duty 3 and back to Duty 2 is

the same for every size and type of paper. However:

• The level of the duty, that is, the amount of suction applied by varying the speed of the motor, is

different for each paper size (width) and paper type.

• As a general rule, Duty 1 is the highest setting to ensure that the leading edge of the paper remains

flat as it passes over the platen.

• The duty settings for thicker paper are much higher than those for thinner, lightweight paper.

• The duty settings are selected automatically as soon as paper size and type are selected for the

job.

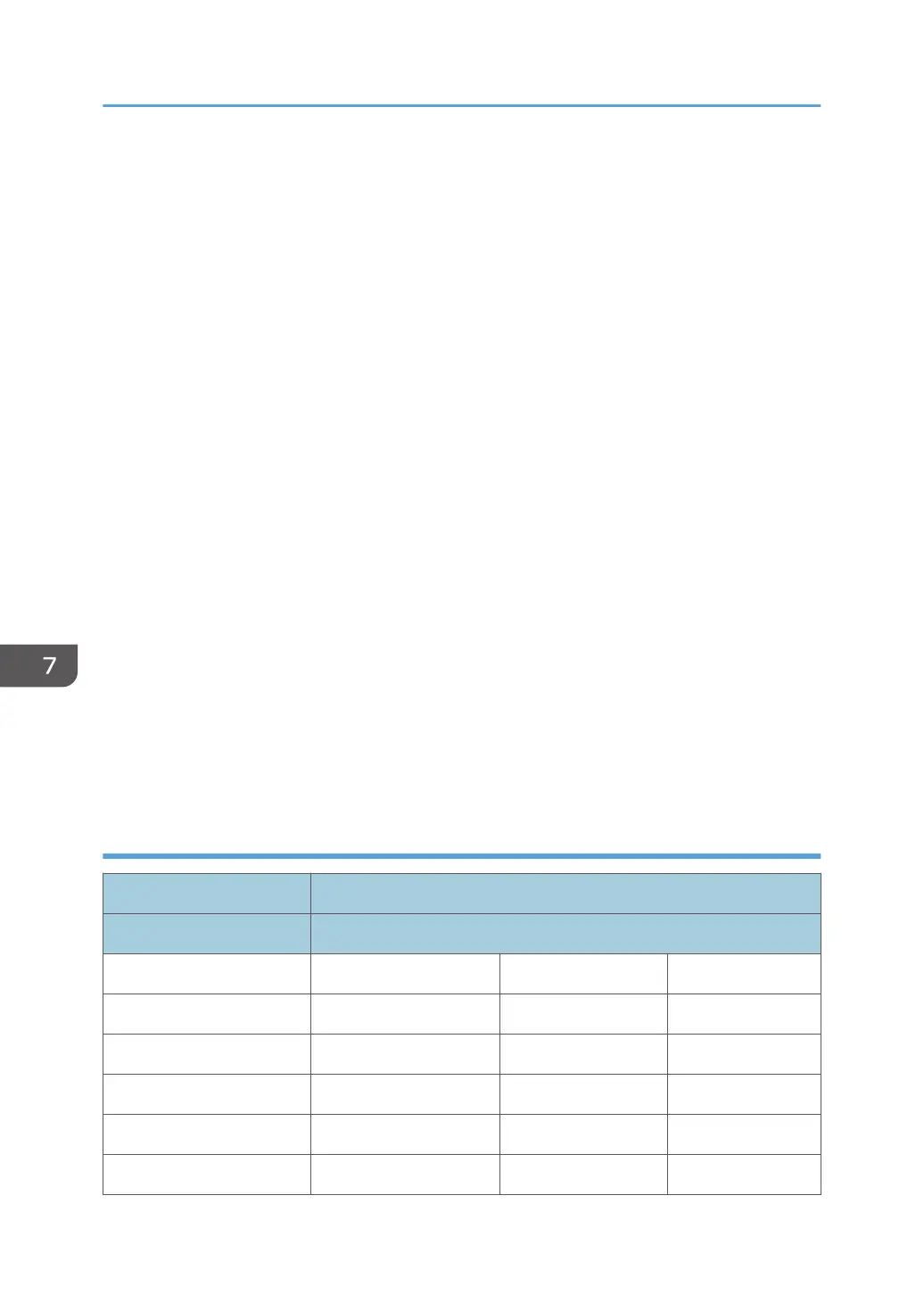

The duty levels are set according to paper type, width and thickness for each type of paper:

• Normal, recycled paper

• Ink jet paper

• Translucent paper

• Coated paper

• Matte film

• Special paper

For example, note the differences in the duty levels for normal paper and translucent paper, especially

for wider paper.

Normal Paper, Recycled Paper

Thin Duty[%]

Normal Duty[%]

Width: mm Duty 1 Duty 2 Duty 3

279.4 to 420 30 30 30

420 to 620 30 30 30

620 to 841 30 30 30

841 or wider 30 30 30

Width: mm Duty 1 Duty 2 Duty 3

7. Detailed Description

816

Loading...

Loading...