After Air Purging

After every air purging:

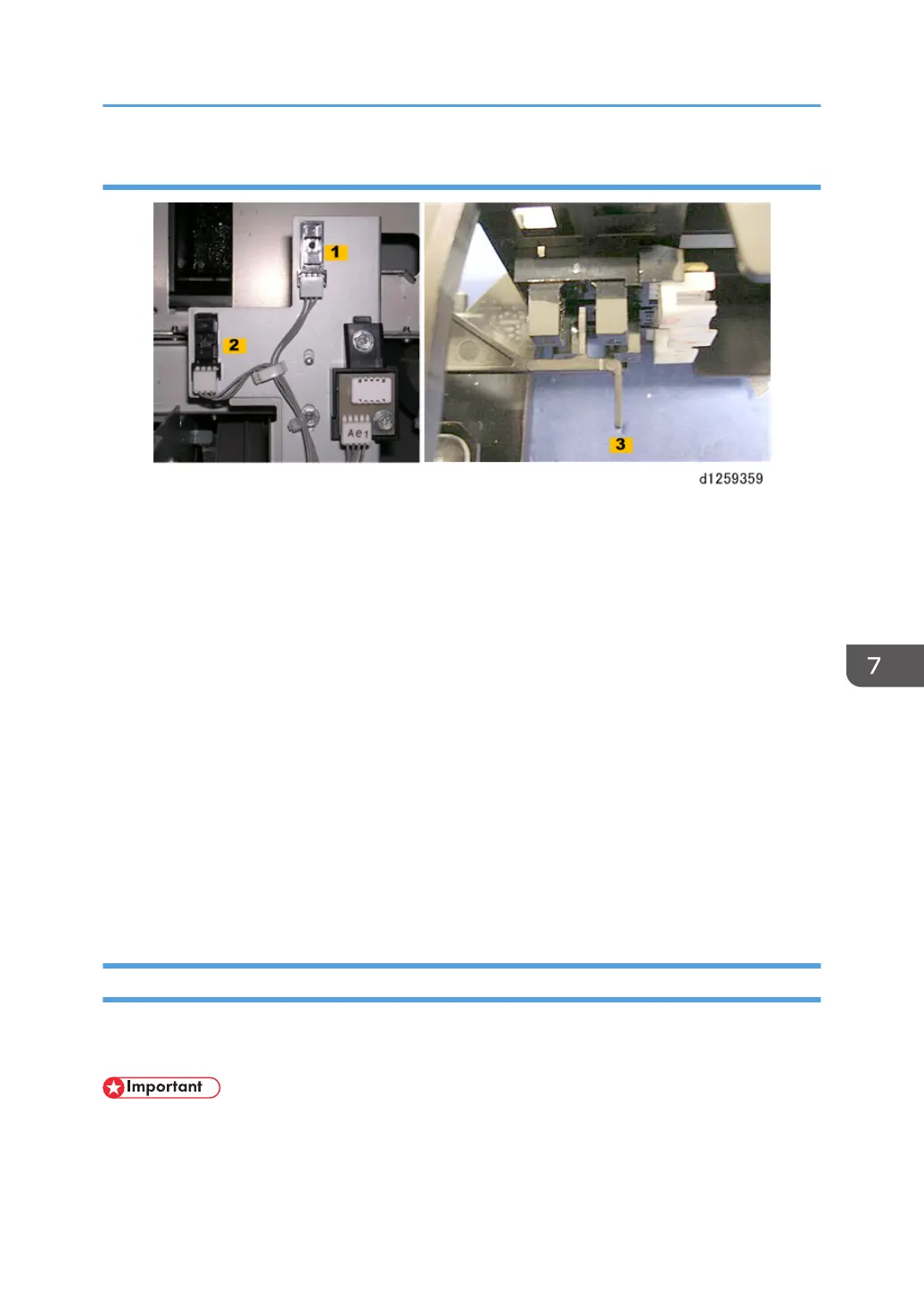

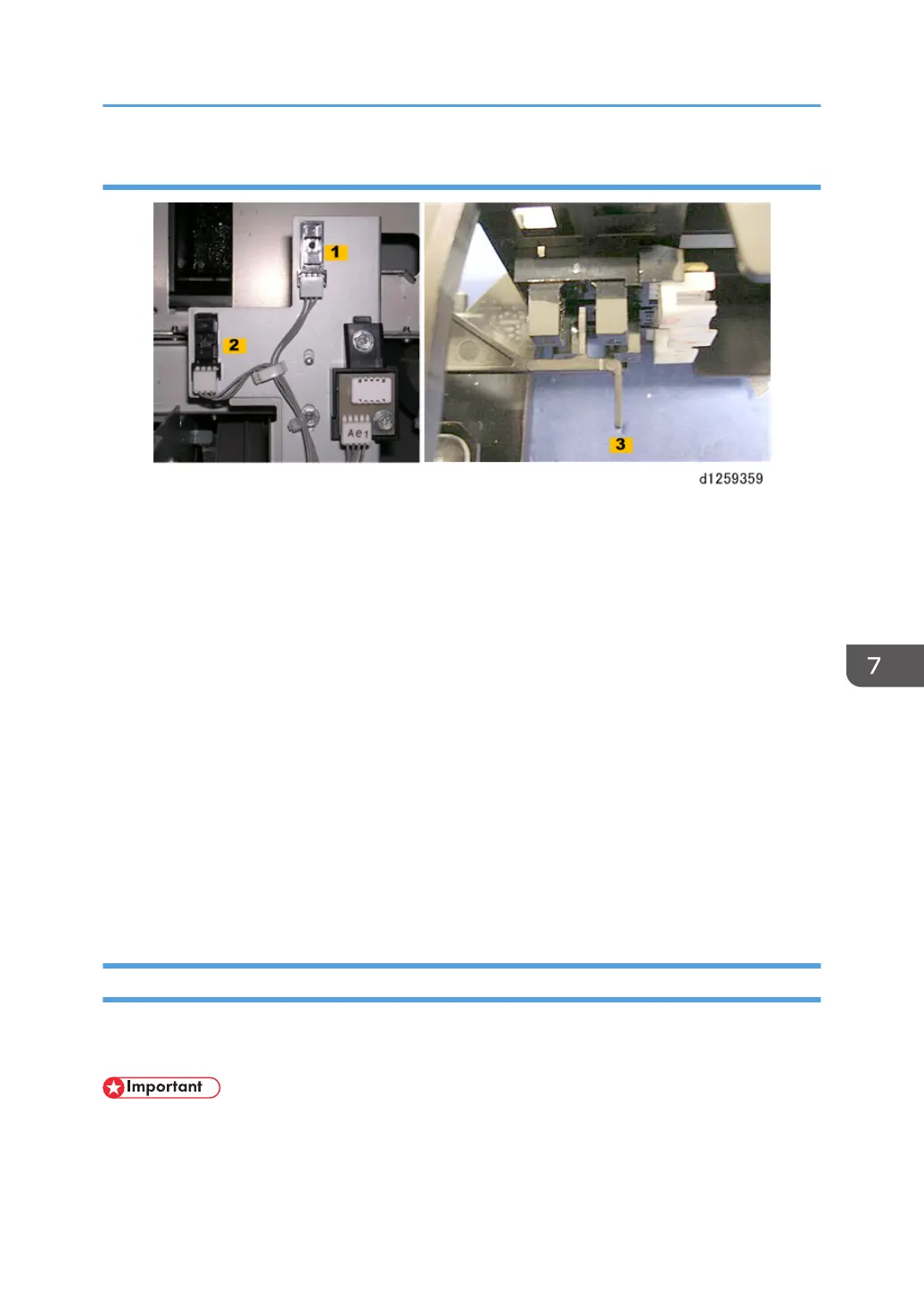

1. The carriage moves to the main ink level sensors [1] and [2]..

2. The carriage stops when the lower actuator [3] on the OCFS sensor feeler enters the main ink level

sensor.

• Main ink level sensor 2 [1] detects the actuators of K2, C, Y, and M.

• Main ink level sensor 1 [2] detects the actuator of K1 only.

• Two main ink level sensors are required because the K1 print head is not level with the other 4

print heads.

3. The machine records how far the carriage has moved along the horizontal encoder, and stores this

as the new "Tank Full Position".

4. At the end of a job, the machine moves the carriage to the main ink level sensor to compare with

the most recent Tank Full Position.

• This sequence is also done at cleaning and flushing.

• The carriage does not move to this sensor during printing. (Ink level during printing is checked

with the OCFS sensors.)

Emergency Print

When ink in a color cartridge runs out, only monochrome printing can be continued under certain

conditions.

• Even if only color ink runs out, monochrome printing cannot be continued under some conditions.

Printing volume cannot be guaranteed. Cartridge change is strongly recommended.

Ink Supply

837

Loading...

Loading...