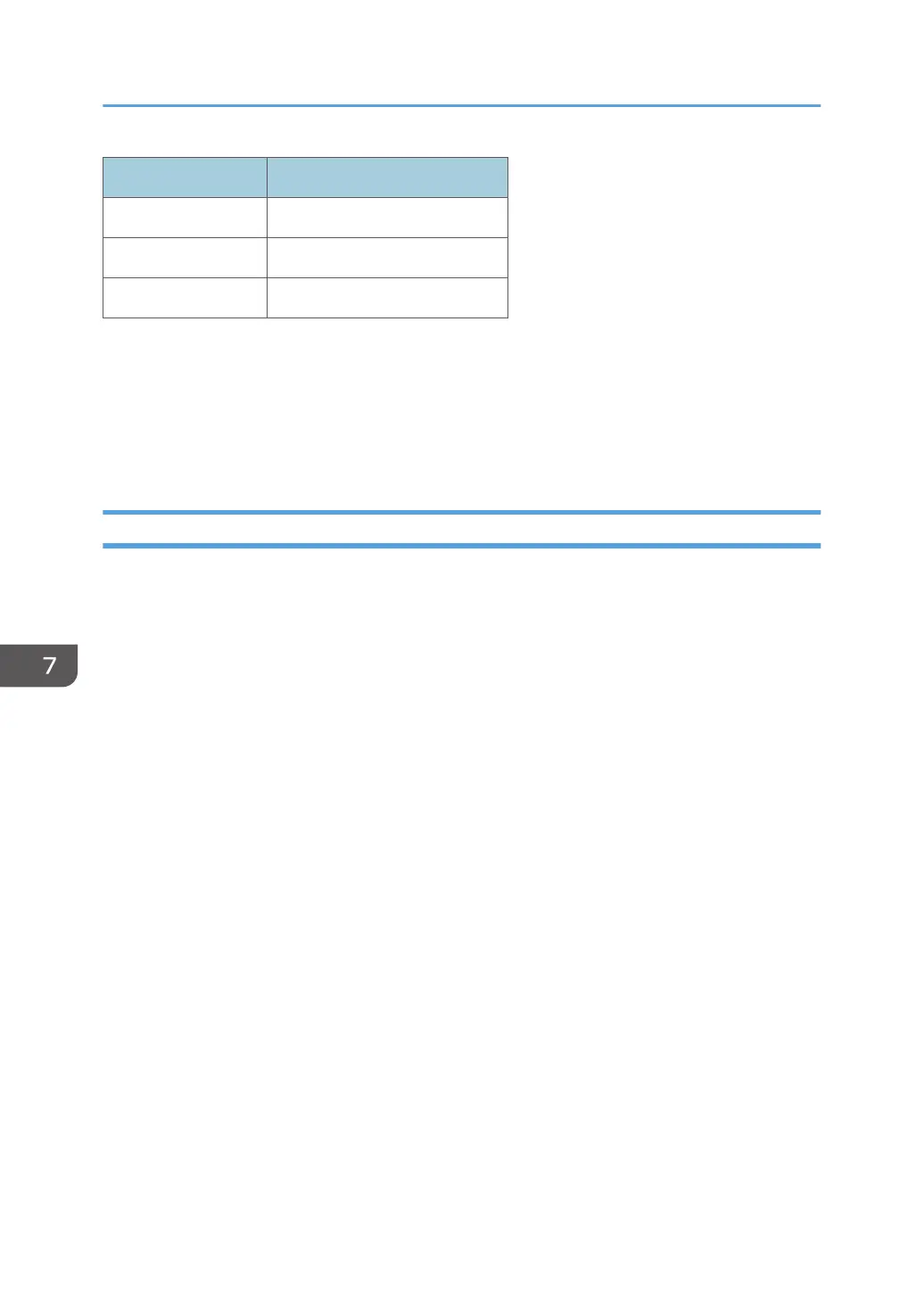

Steps Range (rH%)

1 Up to 35%

2 35% to 65%

3 65% and over

• Temperature and humidity are always sampled by the temperature/humidity sensor immediately

before a scheduled daraining.

• Normally, draining is done in this order: Color heads Y1M1, C, Y2M2 and then Black heads K1,

K2 with no delay between color and black purging.

• Draining may be slightly slower at cooler temperatures around 15°C (59°F)

Related SPs

• 1-002-XXX [Print Position Adj (Left Edge)]:

This SP adjusts the horizontal registration of the image area on paper for each paper feed station.

This adjustment determines where the moving carriage starts and ends printing with every

horizontal pass across the paper.

• 7-212-XXX [User Cleaning]:

This SP displays the number of print head cleanings executed manually. Print head cleaning can be

done with the User Tools.

• 7-213-XXX [User Refreshing]:

This SP displays the number of print head flushings executed manually. Print head flushing

(refreshing) can be done with the User Tools.

• 2-513-XXX [Mainten. after Leftover Thresh` DFU]:

Even with the print heads capped, if the machine remains idle for a long period, this can cause the

ink around the nozzles to dry slightly and become too viscous to produce good quality images. To

prevent this, the machine will execute a maintenance cycle appropriate for the length of time that

the machine has remained idle. This is done automatically without intervention by the operator after

the machine is turned on, or after a print head has not been used for a long period of time.

• 2-514-XXX [Auto Cleaning Start Threshold DFU]:

This SP code sets the threshold setting to trigger automatic cleaning, based on the mist count.

• 2-517-XXX [Mainten. after Leftover Info.]:

The machine executes a maintenance cycle at power on, and at the start of a print job after it has

remained idle for a significant length of time.

• 2-520-001 [Mainten. after Leftover Setting -On/Off Switch]:

7. Detailed Description

874

Loading...

Loading...