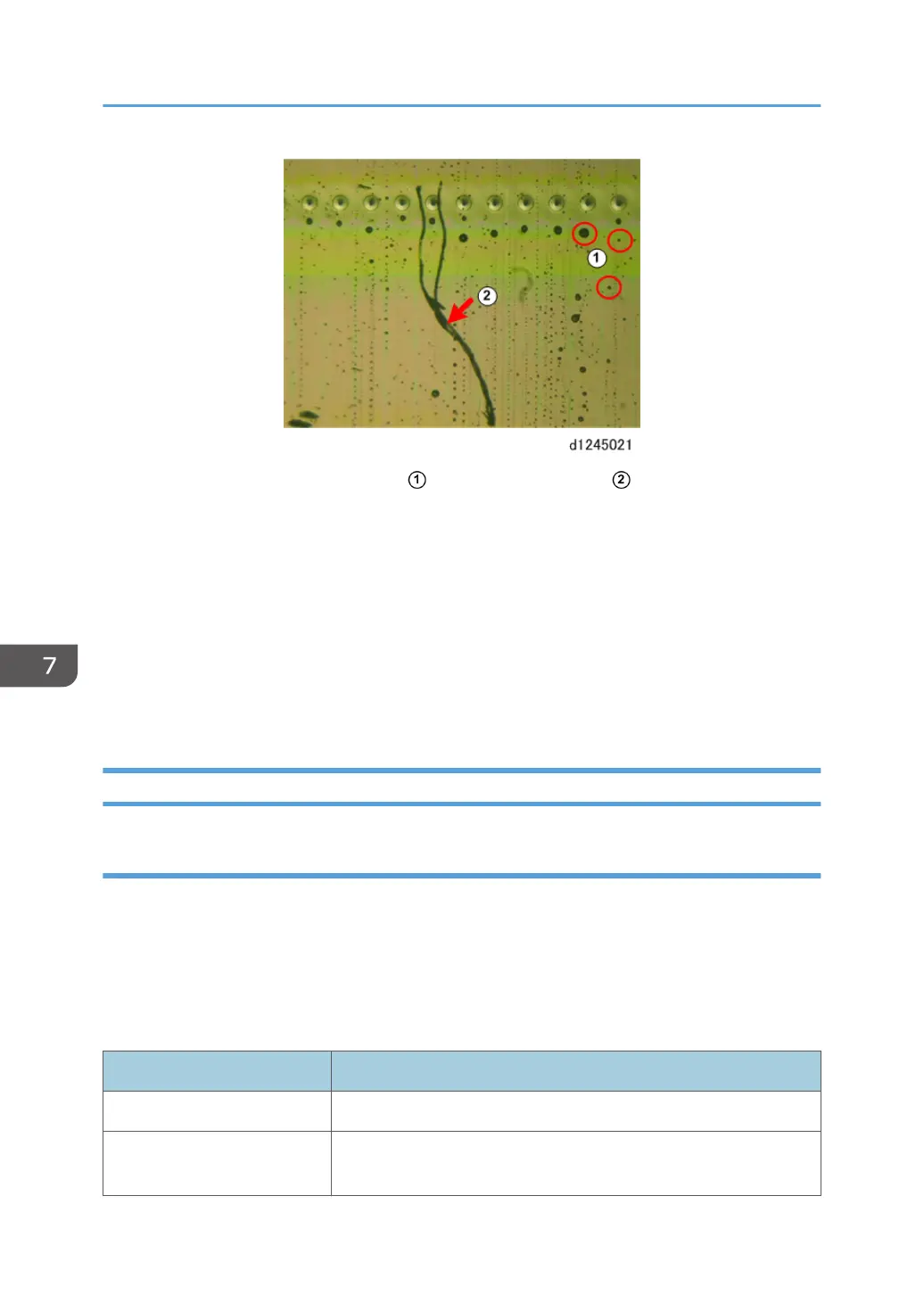

The illustration above shows droplets of mist and paper fibers and dust that can collect near the

nozzles. This undesirable condition is corrected with periodic automatic cleanings while the printer is in

use, greatly extending the length of time the machine can be used without operator intervention.

• Mist count. A "mist count" triggers automatic cleaning. This mist count can be extended to increase

the timing between automatic cleanings. The mist count, which determines the intervals between

automatic cleanings, has been doubled for this machine.

• Count adjustment. The count is automatically adjusted for the width of the paper and total print

area.

• Paper dust count. The paper dust count (the total number of pages printed, cutting count) is used to

determine when cleaning is done for paper dust.

Auto-Nozzle Check Module

Overview

The auto-nozzle check function detects whether the nozzle drops ink correctly. It checks the change in

electrical charge caused by the ink dropped to the electrode plate at constant intervals. If ink is not

dropped well but the effect is not so serious, the adjacent nozzles drop larger dots for printing to

minimize the effect. If the effect is serious, the print head is cleaned automatically.

The part on which the electrode plate and slider are placed is called the holder. It is made of plastic to

maintain high voltage of the electrode and insulation properties of GND.

Name Function

Electrode plate for detection Placed facing the nozzle and charged to 500 V when detecting.

Wiper Wipes ink from the electrode with the slider after ink drop detection

process.

7. Detailed Description

864

Loading...

Loading...