Automatic Downtime Cleaning

Ink can thicken or dry around the nozzles if the print heads remains idle for a long time, especially at

low temperatures. This can affect the quality of printing. To prevent the drying or thickening of ink around

the nozzles, the machine will execute a maintenance cleaning cycle appropriate for the length of time

that the print heads have remained idle. This is done automatically without intervention by the operator.

The machine monitors two phases of downtime.

• Idle time 1: Starts after the last sheet exits and all the print heads are capped

• Idle time 2: Amount of time each head has remained idle

• Idle (or downtime) refers to the length of time that a print head has not been used. For example, If

the machine is used for extensive black-and-white copying and printing over a period of several

days, a count of idle time for the color print heads (C, YM) is maintained even though the machine

has not been turned off.

These idle time counts are used to execute these operations:

• Air purging (ink supply and purging, filling and cleaning, and air purging/filling together)

• Ink supply sequence

• Cleanings and flushing (refreshing) done by the operator manually

• Ink purging done after idle time

The type of maintenance operation is selected and executed automatically based on the time elapsed

from the start of downtime.

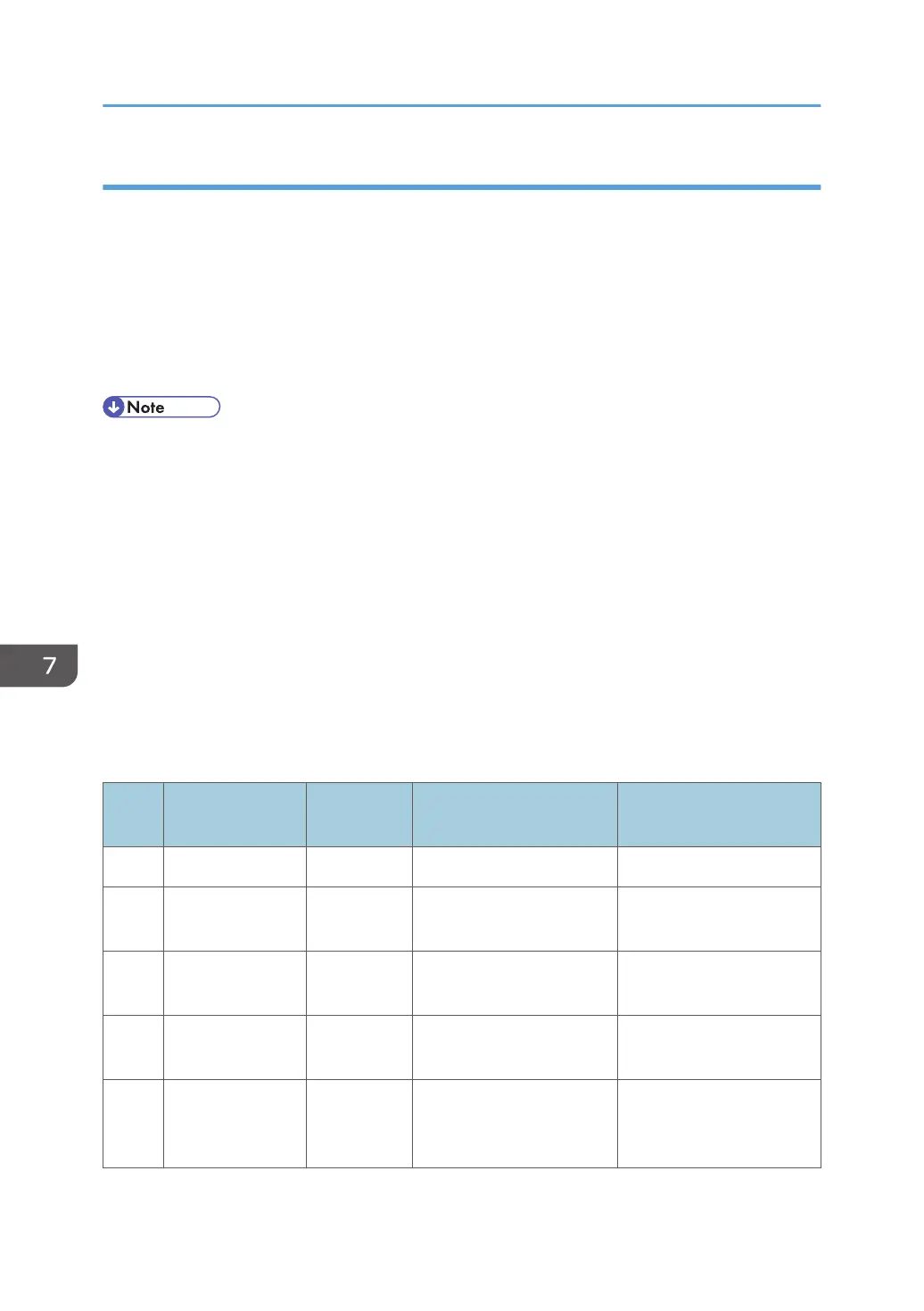

Maintenance Cycles Based on Idle Time

No. Downtime Try to Detect

Air?

If air is detected for a print

head*

1

If no air detected

1 < 10 h No --- ---

2 > 10 and < 24 h Yes Ink supply, air purge/ink

fill sequence

Small downtime ink purge

3 > 24 h and < 3

days

Yes Ink supply, air purge/ink

fill sequence

Large downtime ink purge

4 > 3 days, < 7

days

Yes Ink supply, air purge/ink

fill sequence

Large downtime ink purge

3 times

5 > 7 days and <

45 days

Yes Ink supply, air purge/ink

fill sequence > Downtime

cleaning

Downtime cleaning

7. Detailed Description

862

Loading...

Loading...