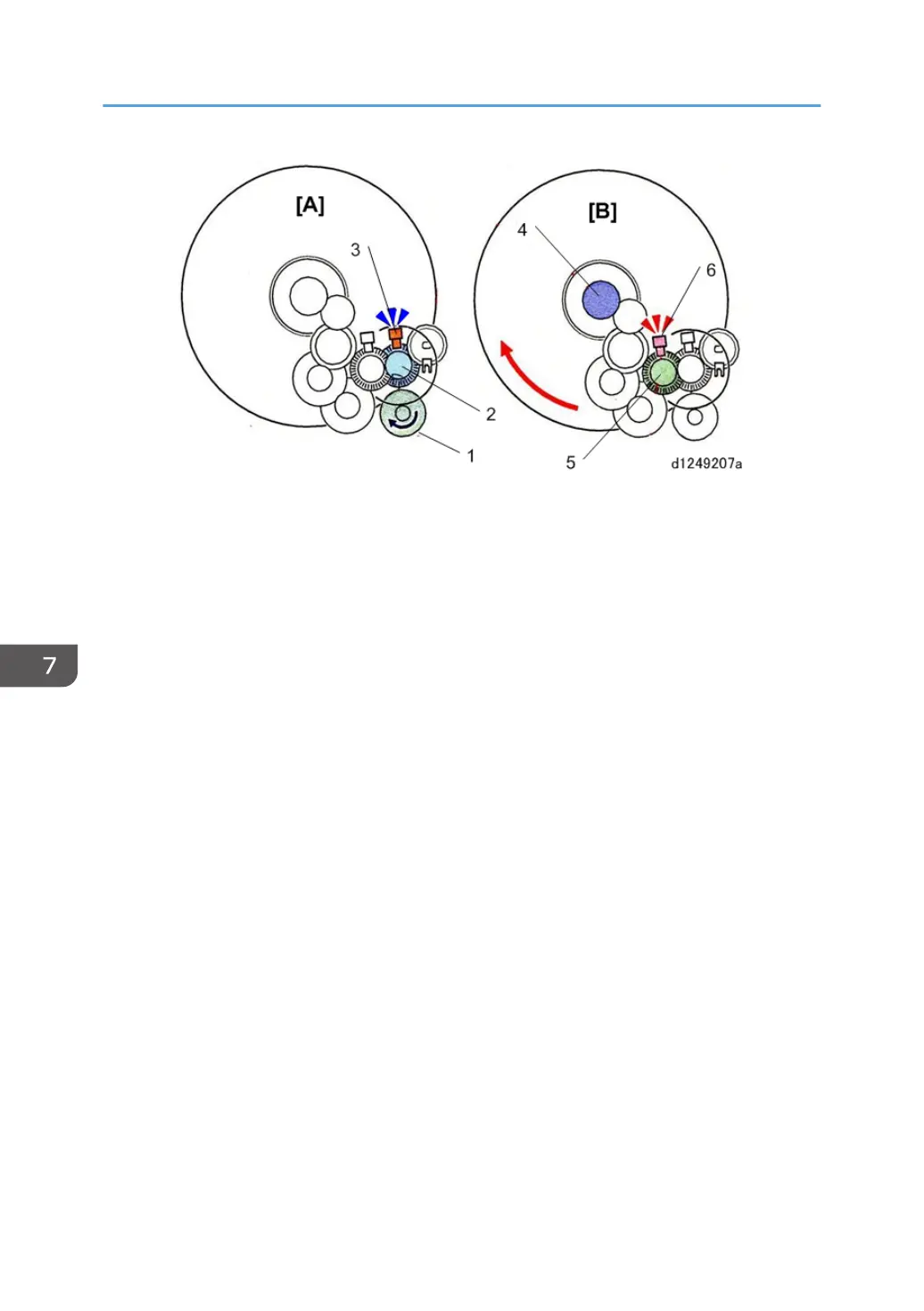

To tally a count for the operation time of the motor [A]:

• The roll paper feed motor (1) and encoder wheel 1 (2) rotate together.

• Encoder sensor 1 (3) counts the rotations of the encoder wheel.

• The encoder wheel and sensor always monitor the motor while it is operating.

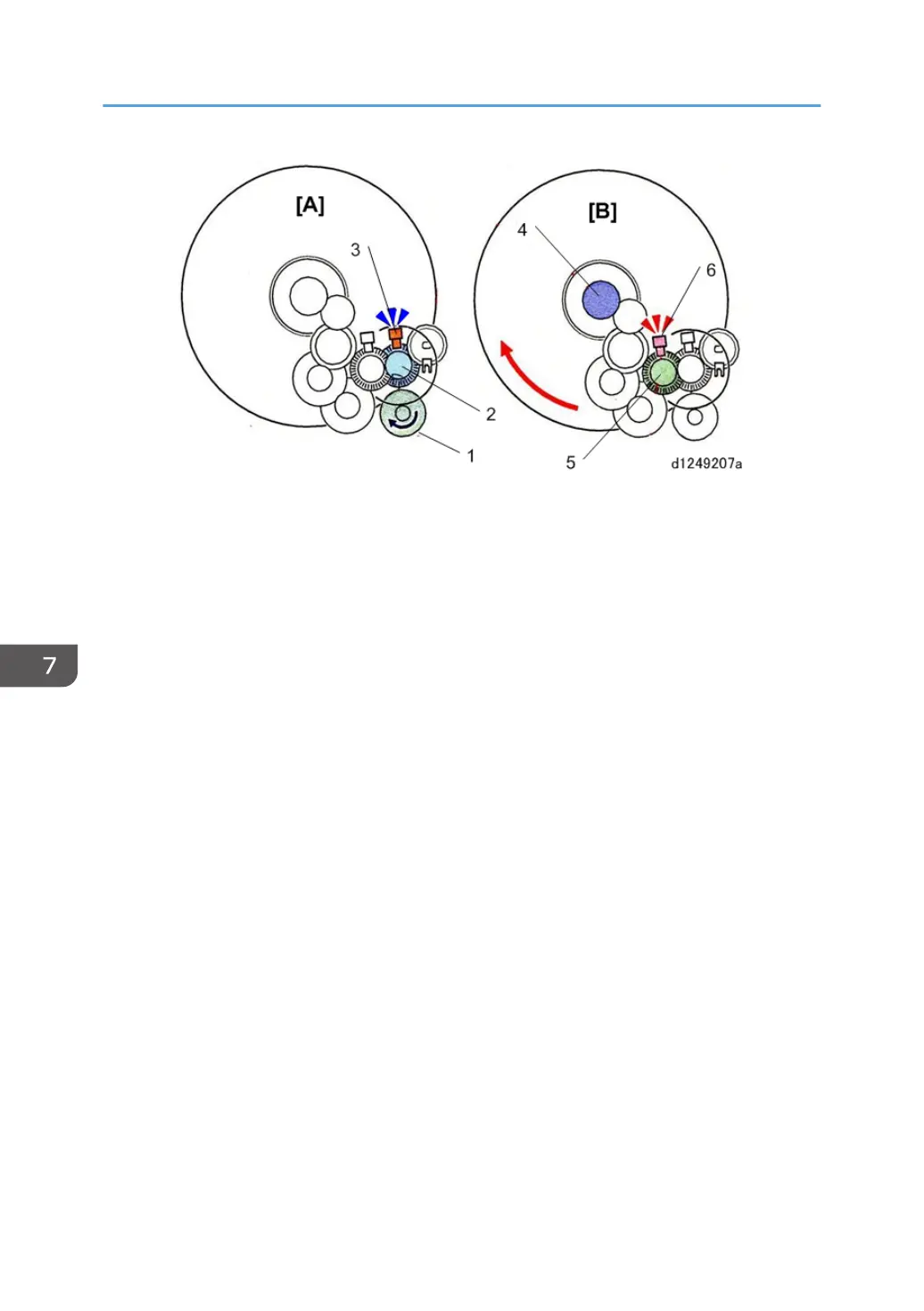

To tally a count for the remaining paper calculation [B]:

• The core of the roll (4) and encoder wheel 2 (5) rotate together.

• Encoder sensor 2 (6) counts the rotations of the encoder wheel. The machine uses the pulse count

to calculate how much paper remains on a paper roll.

The encoder wheel and sensor count the rotations of the roll core when the machine feeds paper out of

the machine, and then reverse feeds the leading edge of the paper to the registration standby position.

This is done at the following times:

• When the roll is replaced or swapped for another roll.

• When the paper is fed back to the registration standby position after the paper is cut at the end of a

job.

• When the other paper roll is selected for paper feed. For example, if paper from Roll Unit 1 is at

the paper registration position, and Roll Unit 2 is selected.

The machine calculates the amount of paper remaining on a roll based on the diameter of the roll and

the number of rotations made by the core, and then displays the amount of paper remaining as it

diminishes.

• The encoder wheel and sensor, and a small PCB in the roll unit, comprise the device that measures

the amount of paper remaining on the roll.

• The residual paper detection encoder is a small wheel with 40 slits (spokes) around its center

capable of generating 503 pulses with one rotation.

5-Step Operation Panel Display

7. Detailed Description

812

Loading...

Loading...