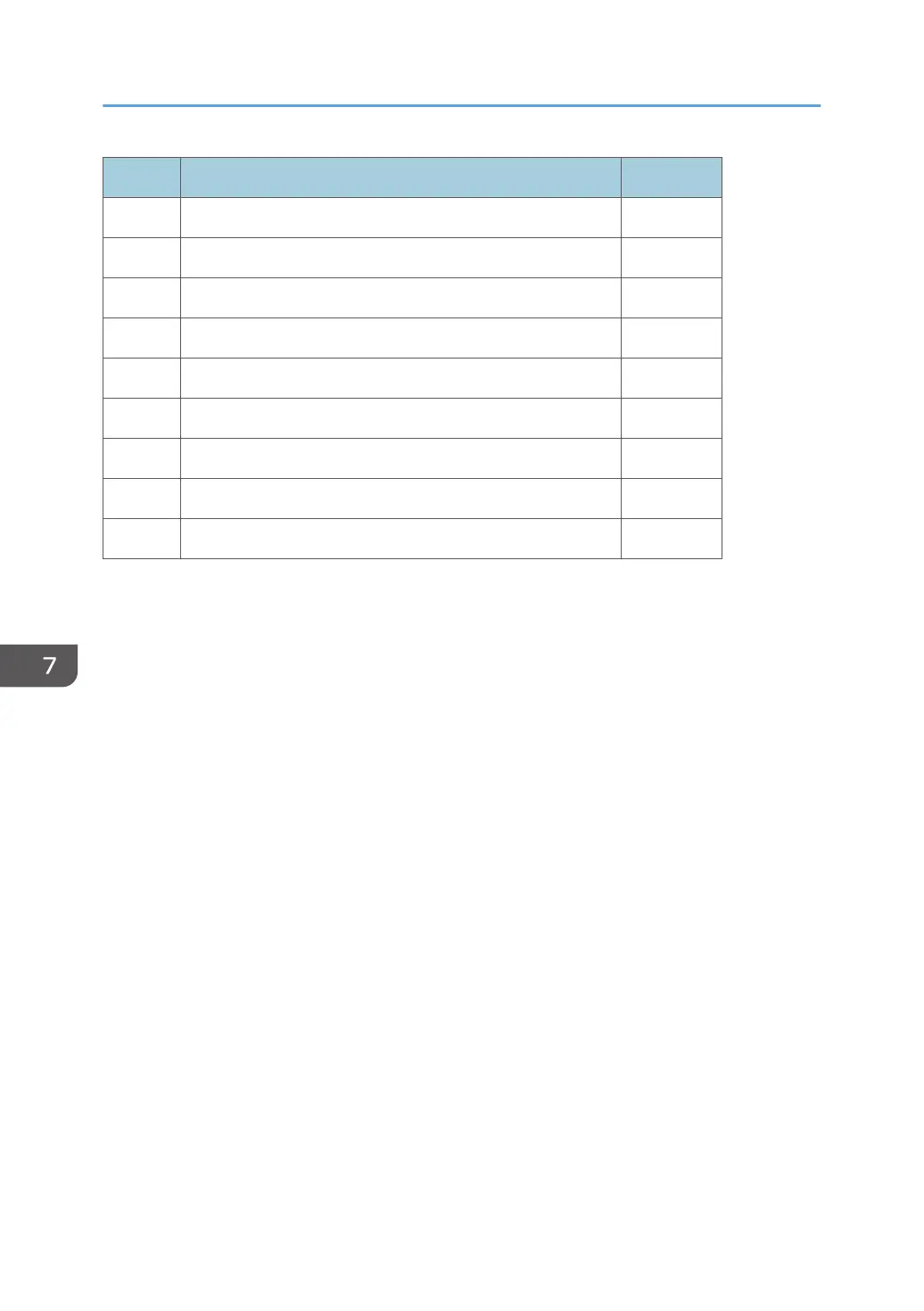

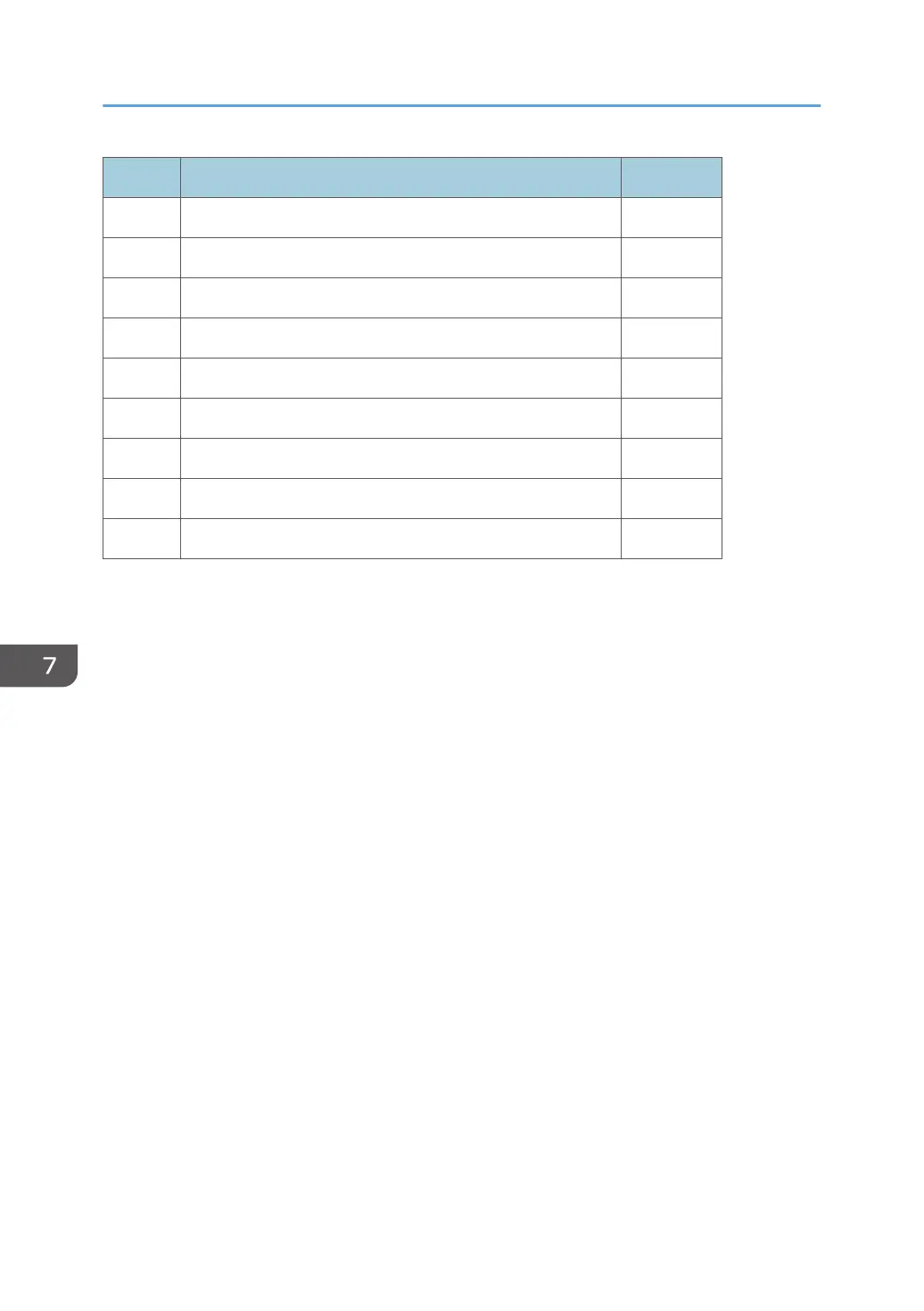

No. Item Qty

3 Print head sub tanks 7

4 Main ink level sensor 1 1

5 Main ink level sensor 2 1

6 Ink supply unit 1

7 Ink cartridges 4

8 Ink end sensors 1

9 Ink supply tubes 7*

1

10 Ink pump cams 7

11 Ink pump motors 7

*1 There are four short ink supply tubes (one for each cartridge) between the ink cartridge port and the

pumps. The black tube splits into two supply tubes before the pumps, one for K1 and one for K2,

bringing the total of tubes to 5.

• The ink supply unit (6) houses the ink cartridges, the lower end of the ink supply tubes, and the ink

pumps.

• The ink supply unit holds four replaceable ink cartridges (7), one for each color (K, C, Y, M). The

black cartridge (K) is larger than the other three.

• The ink end sensor (8) detects when the cartridge is out of ink. This is a new component with this

machine.

• The ink supply tube (9) transports ink from the ink cartridges to the print head unit in the carriage

unit. The tube is flexible yet sturdy enough to prevent kinking and blocking the flow of ink.

• The ink pump cam (10), driven by the ink pump motor (11), rotates against the ink supply tube to

force ink through the tube.

• The air release solenoid (1) provides pressure to push excess air out of the print head sub tanks.

• The print head sub tanks (3) (1 for C and 2 each for black, M and Y) hold the ink supplied to the

print heads from the ink pumps of the ink supply unit.

• The OCFS (2) (one sensor and one feeler for each sub tank) is mounted in front of the carriage unit.

The sensor is above the actuator of the feeler attached to the side of the sub tank. This feeler and

actuator monitors the level of ink in each sub tank and triggers an alert when ink runs low.

7. Detailed Description

828

Loading...

Loading...