PM Table

SM 2-1 J007/J010/J011

J007/J010/

J011

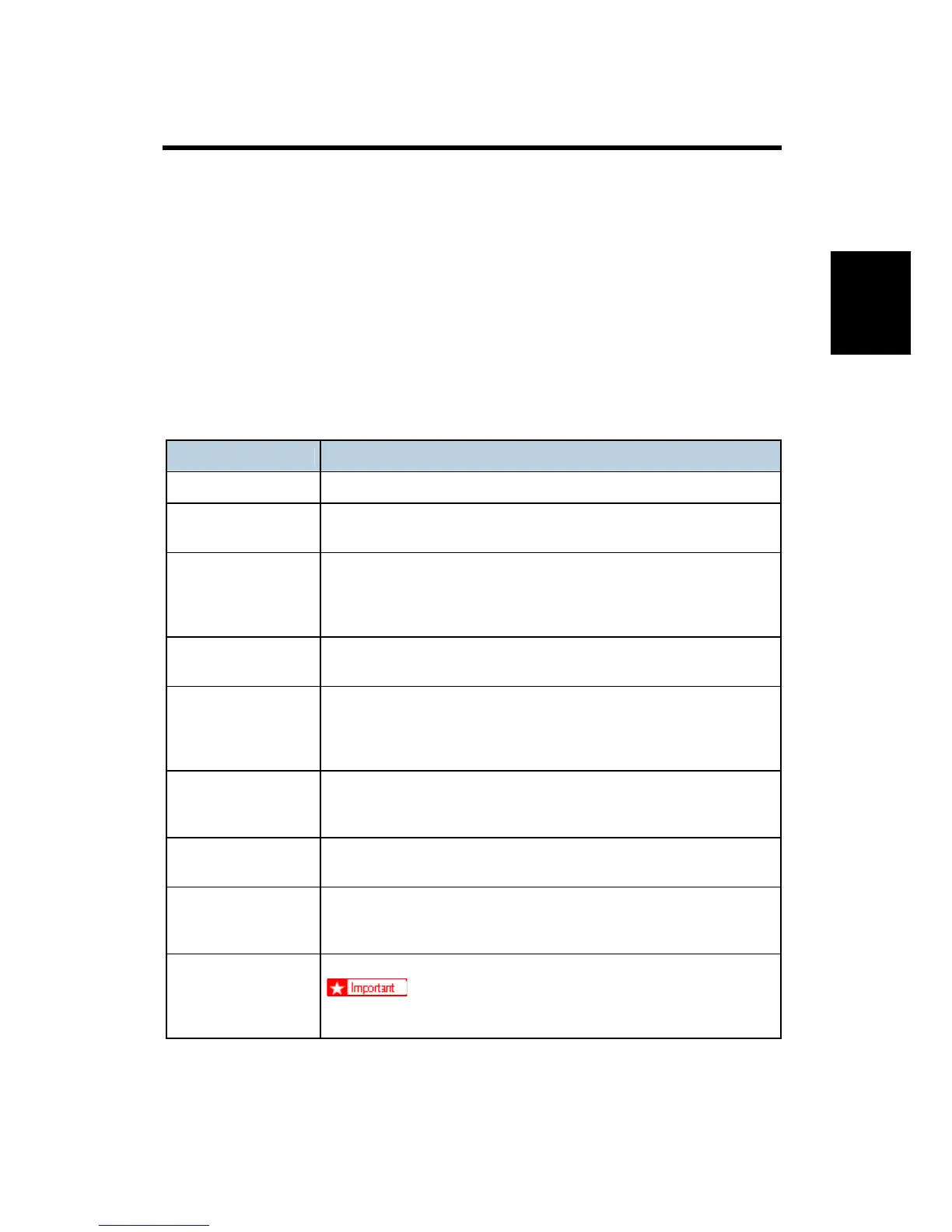

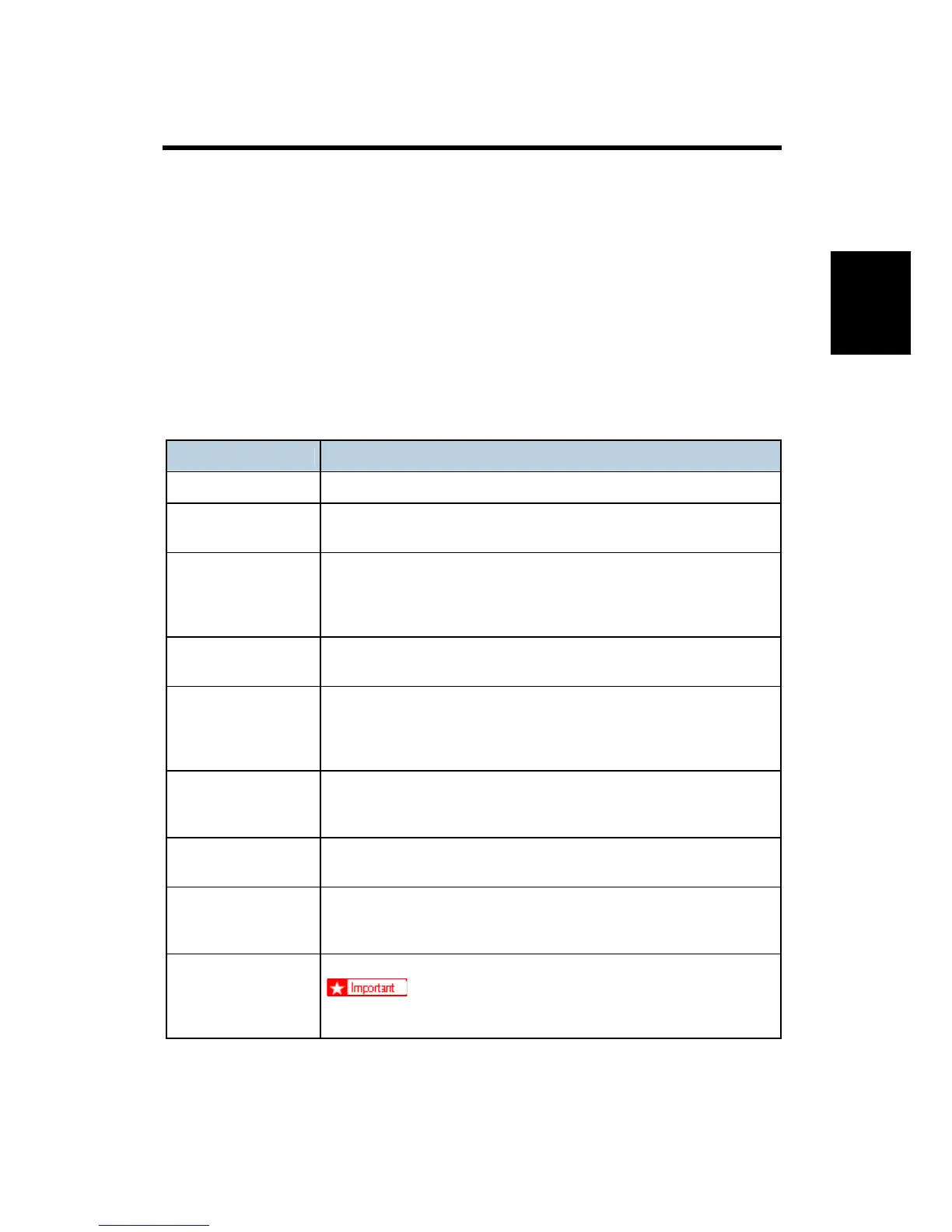

2. PREVENTIVE MAINTENANCE

2.1 PM TABLE

There are no maintenance procedures prescribed for periodic care or replacement.

However, the "Service Call Procedures" listed below should be done by the service

technician. For more details about how to do these procedures, please refer to "Cleaning

Procedures" in Section 3.

Service Call Procedures

Description At Service Call, or As Required

External Covers Damp cloth.

Feed Roller Damp cloth. Release the feed clutch lock. Rotate the roller freely

as you clean it.

Flushing Unit Gate Dry cloth. Always remove the ink that has hardened around the

flushing gate when you replace the waste ink tank. To remove

hardened ink, you may need to use a small screwdriver or similar

tool.

Friction Pad Damp cloth. This is the cork friction pad on the front edge of the

standard paper cassette.

Ink Collection Tank Replace when SC992 appears. The waste ink tank is full, or when

the display prompts that the printer needs maintenance. Open the

printer driver to confirm either condition. For more, see section "3.

Replacement and Adjustment".

Maintenance Unit Dry cloth. Always use a tightly wrapped dry cloth to remove the

ink that has hardened around the suction cap and wiper blade

when you replace the waste ink tank.

Print Heads Dry cloth. Gently wipe clean the print head nozzles and nozzle

loop plates on the front side when you replace the waste ink tank.

Printer Operation,

Print Quality

Print a Nozzle Check Pattern. Then check the results. Clean the

print heads if necessary. For more, see "Image Adjustment" in

section "3. Replacement and Adjustment".

Transport Belt Damp cloth. Then dry cloth.

To protect the surface of the transport belt, never use

alcohol or any other type of organic solvent.

Loading...

Loading...