Carriage Unit

SM 6-9 J007/J010/J011

J007/J010/

J011

port.

This device is unique. Other printers on the market use small heaters that form bubbles to

eject ink from the ports.

6.3.5 INK NEAR END

The printer detects ink near-end in two ways:

The printer software maintains a count of how much ink is consumed from each

cartridge and signals near-end when a cartridge is nearly empty.

As a backup method, the ink level sensor monitors the positions of the ink level levers

on the sides of the ink tanks. This is described below.

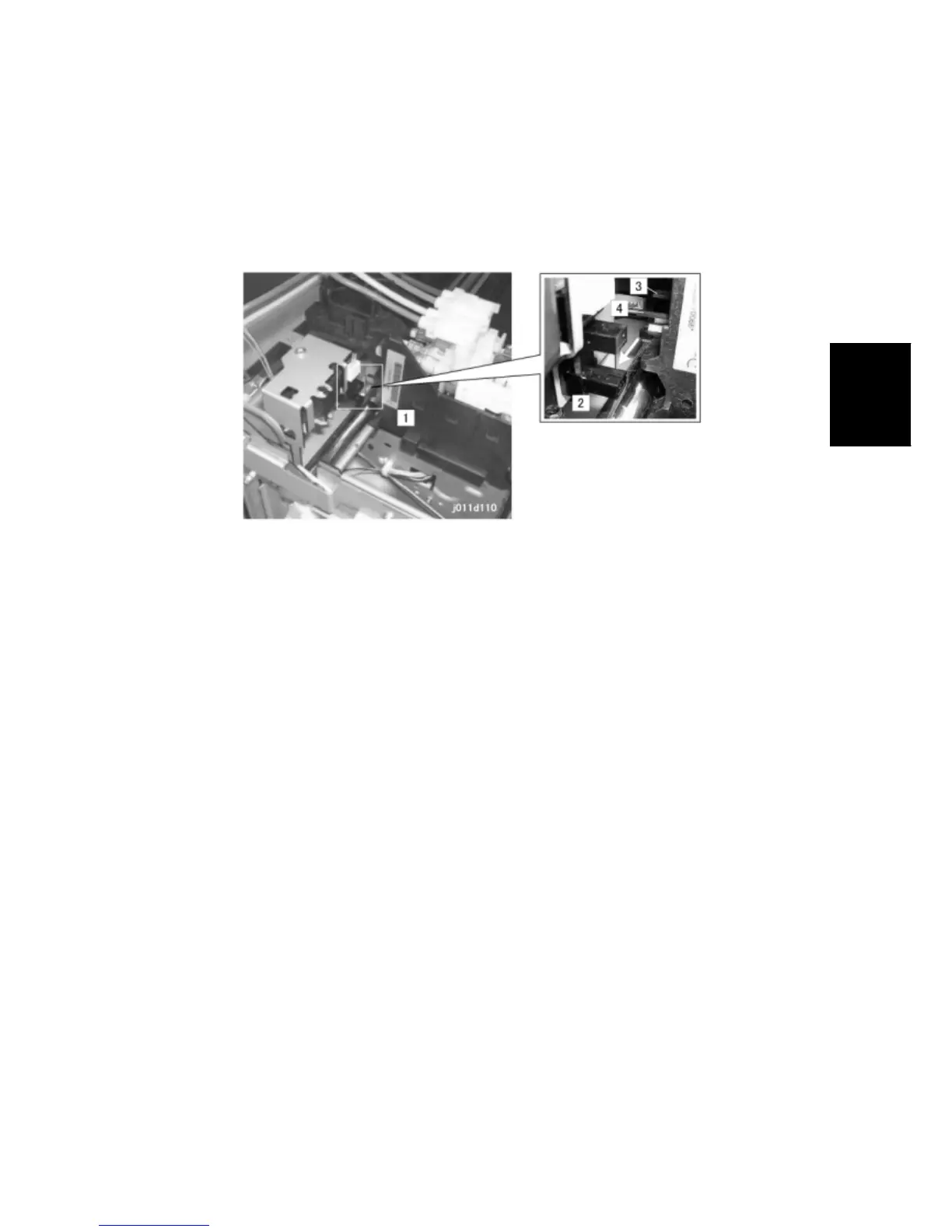

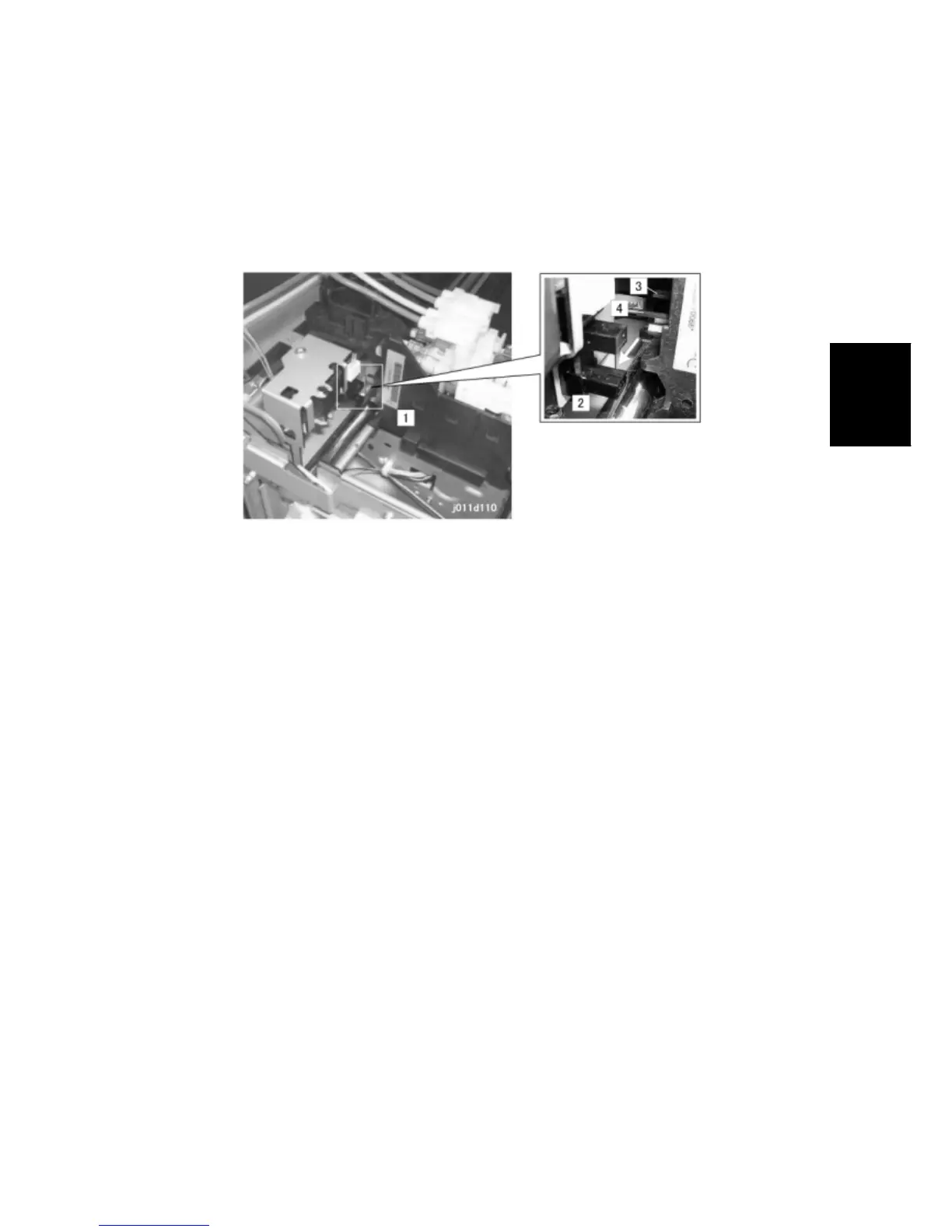

Each print head in the ink tank unit [1] has a ink level lever This lever presses against a

spring loaded bellows in the center of the print head tank. The right side of each tank is

constructed of flexible plastic:

As ink enters the tank, the pressure of the ink pushes against the side of the tank and

moves the lever away from the side of the print head tank.

As ink is consumed during printing, the vacuum created by the ink leaving the tank

pulls the lever toward the side of the print head tank.

The ink level sensor [2], mounted above the front guide rail, checks the left and right

positions of the ink level levers [3] and [4] every time the carriage passes.

When the ink level sensor detects that a lever is completely flat against the side of the

tank, the printer sends a prescribed amount of ink to the tank from the ink cartridge.

The sensor signals the ‘ink near-end’ if the ink level lever does not return to the full

position (away from the side of the tank) within the prescribed time after the printer

requests a refill from the ink cartridge.

After the near-end alert, the printer will continue to print with the ink that remains in the

partially filled tank until the printer issues the ink end alert.

Loading...

Loading...