Paper Feed, Transport, Output

SM 6-31 J007/J010/J011

J007/J010/

J011

5. The feeler of the trailing edge sensor depresses and switches the trailing edge sensor

on.

6. When the trailing edge sensor goes on, the carriage moves to the right of center. This

lets the 1st registration sensor detect the leading edge of the paper.

7. The 1st registration sensor also detects the right edge of the sheet when the carriage

and sensor move toward the carriage HP sensor on the right.

8. The detection of the right edge by the 1st registration sensor is used to determine the

width of the paper in the paper path.

The 1st registration sensor reads the right edge of only the 1st sheet of the

print job. Thereafter, the 1st registration sensor does not right edge for any

until the beginning of the next print job.

9. An area equal to the length of each print head gets printed when the carriage goes

across the sheet from right to left.

10. When the last line prints, the transport roller rotates only long enough to feed the

length of the last sheet.

11. The print job count increases by 1 after the paper exits.

6.6.7 TRANSPORT BELT

This printer uses the BT system to transport paper through the paper path.

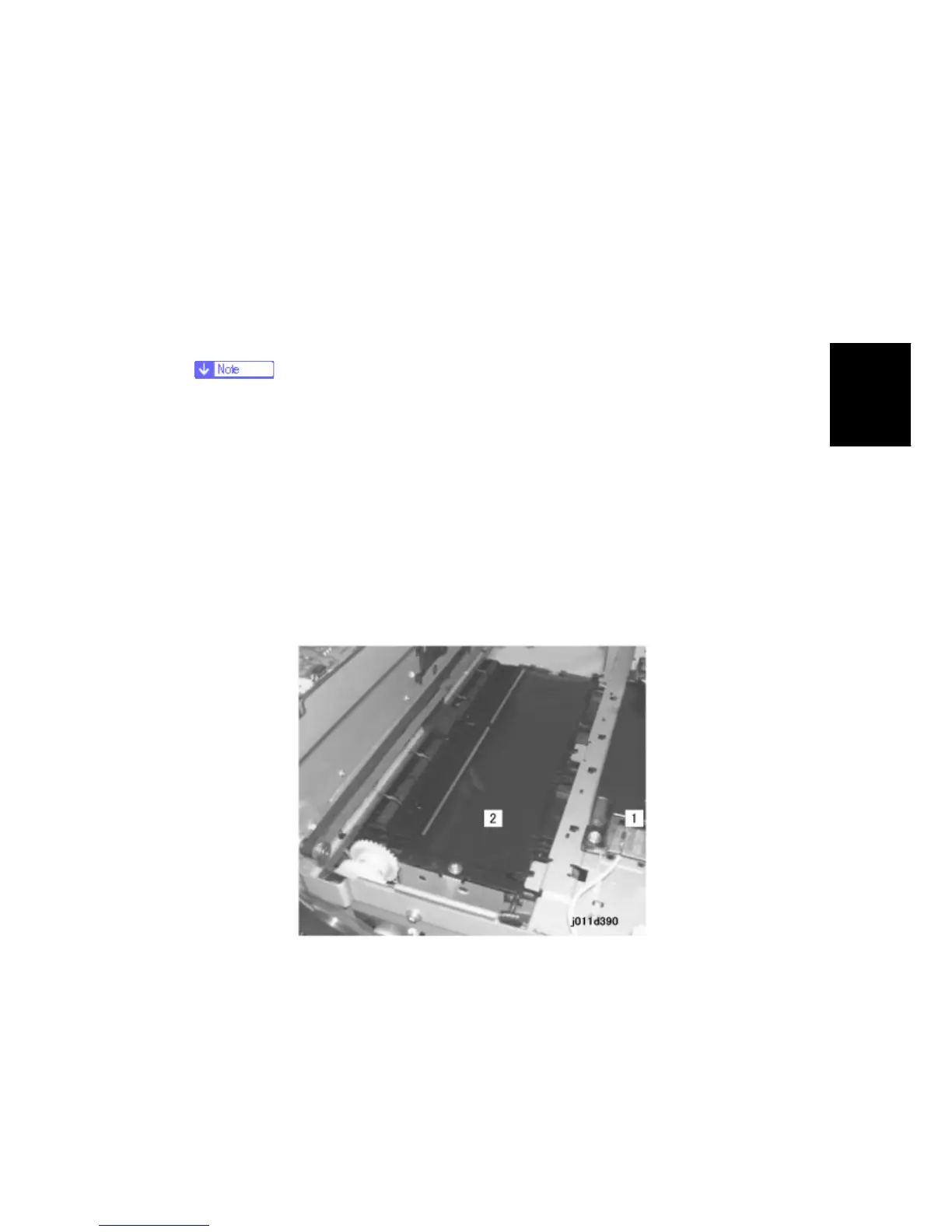

A high voltage power supply pack (HVPS) [1] energizes the charge roller below the

transport belt [2].

The charge roller applies a charge to the transport belt. This static charge attracts the

paper to the transport belt and holds it in place so it does not move during printing.

A temperature/humidity sensor below the transport belt monitors the temperature and

Loading...

Loading...