Paper Feed, Transport, Output

J007/J010/J011 6-30 SM

the feeler, this turns on the trailing edge sensor [2]. The length of time the trailing edge

sensor remains on is used to measure the length of the paper for printing control.

A paper jam alert occurs when:

The paper feed roller rotates forward twice.

The trailing edge sensor does not go on after 2 rotations of the paper feed roller.

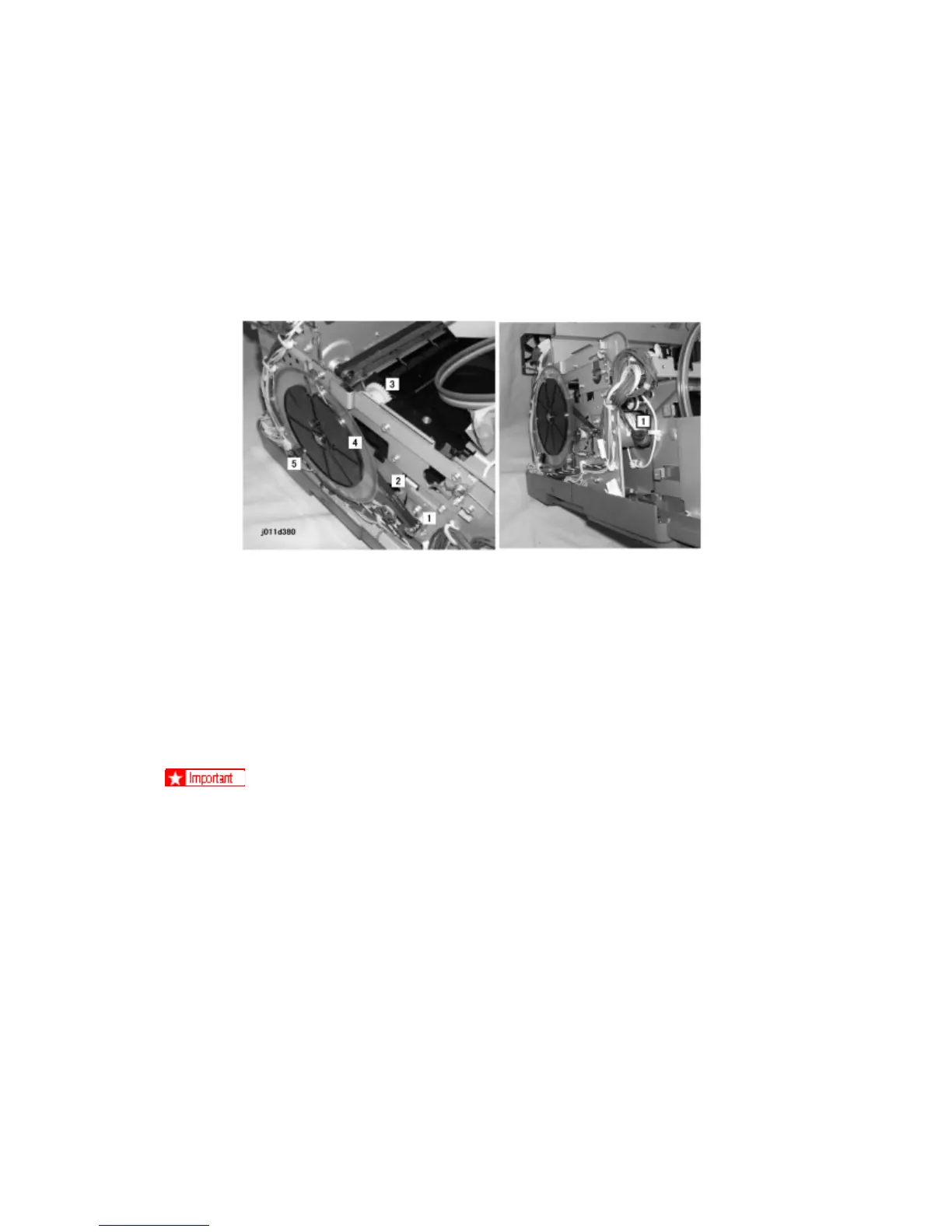

6.6.5 PAPER TRANSPORT DRIVE

The vertical motor [1] drives the timing belt [2] that rotates the transport roller [3].

The rotation of the transport roller also drives the paper feed roller when the paper feed

clutch engages the feed roller (not shown above).

The edge of the vertical encoder [4], attached to the shaft of the transport roller, passes

through the gap of the vertical encoder sensor [5] as the encoder wheel rotates. The

vertical encoder sensor reads the coded markings on the rim of the vertical encoder and

sends this information to the CPU. The CPU uses these readings to control the on/off

timing of the transport belt and the paper feed roller:

When servicing the machine, work carefully to prevent scratching, breaking, or

bending the vertical encoder wheel.

6.6.6 PAPER PATH

Here is a summary of the operation that sends paper through the printer:

1. The feed clutch energizes and engages the feed roller, then the rotation of the vertical

motor drives the feed roller.

2. Paper feed roller feeds 1 sheet from the top of the stack in the paper cassette. A

friction pad at the lip of the paper cassette prevents double-feeding.

3. The charge roller charges the transport belt. The electrostatic charge on the transport

belt keeps the paper on the transport belt.

4. The sheet feeds onto the transport belt.