SP Tables

J007/J010/J011 5-6 SM

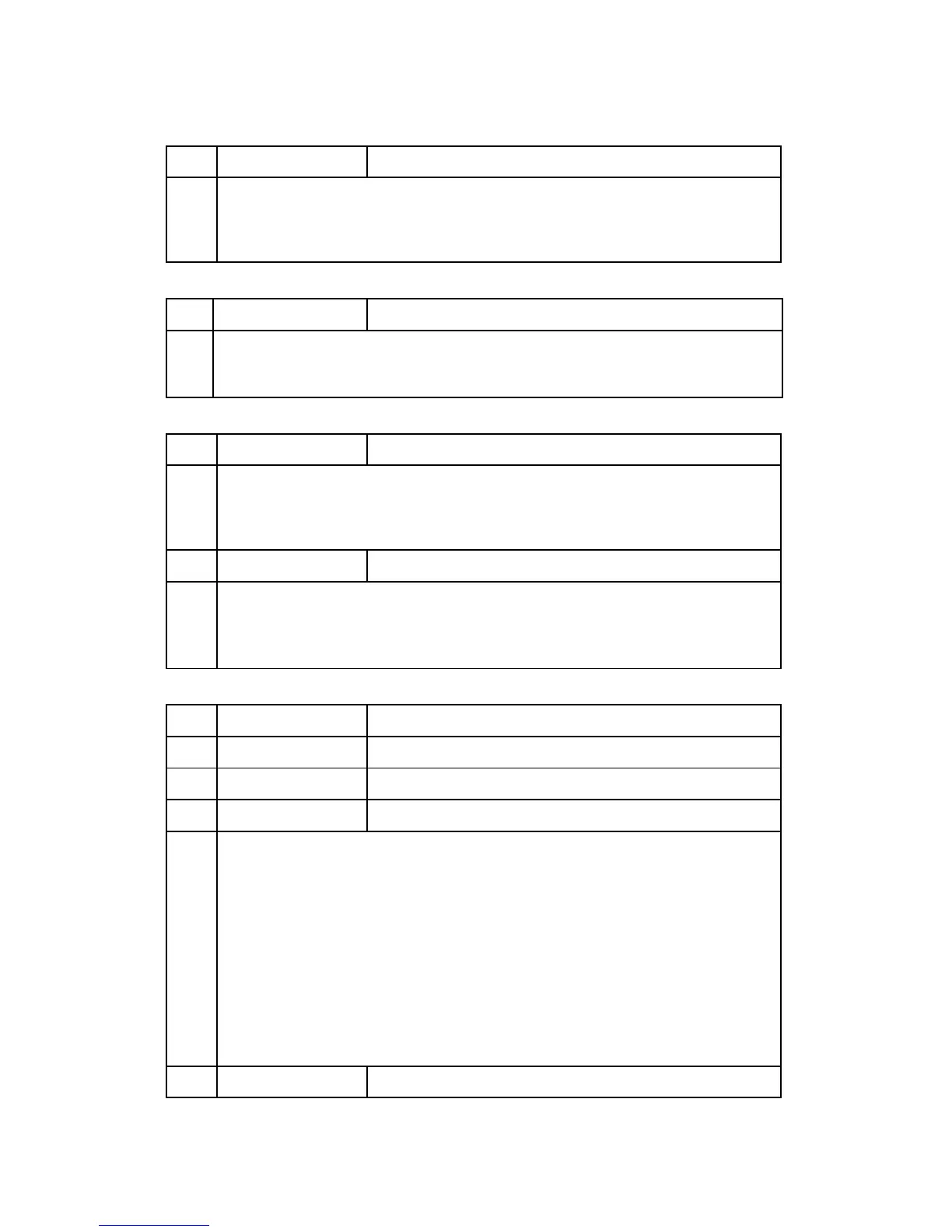

1015 FDLEN:OFFSET Adjust Amount of LF Offset in Sub Scan Direction

Use this SP to set the amount of line feed before the print head begins its 2nd

pass during bi-directional printing. Do this SP when it is necessary to correct

color offset that occurs during bi-directional printing.

[-128 to +128/FA/1/Vertical Encoded Pulse Count]

Carriage

1016 ADJ:SIDEBOARD Adjust Sideboard (Carriage Home Position)

Use this SP to set the reference position for installation of the right plate. Do this

SP to correct the alignment of the capping position with the carriage.

[-128 to +128/FA/1/0.1 mm]

Suction Vents

1017 PRGPORTS:R Adjust Position of Right Suction Vent DFU

Use this SP to adjust the venting position of the right air vent. Do this SP after it

has been determined that the ink is not venting at the center of the right ink

suction vent.

[-128 to +128/FA/1/0.1 mm]

1018 PRGPORS:L Adjust Position of Left Suction Vent DFU

Use this SP to adjust the venting position of the left ink suction vent.(Do this SP

after it has been determined that the ink is not venting at the center of the left ink

suction vent.

[-128 to +128/FA/1/0.1 mm]

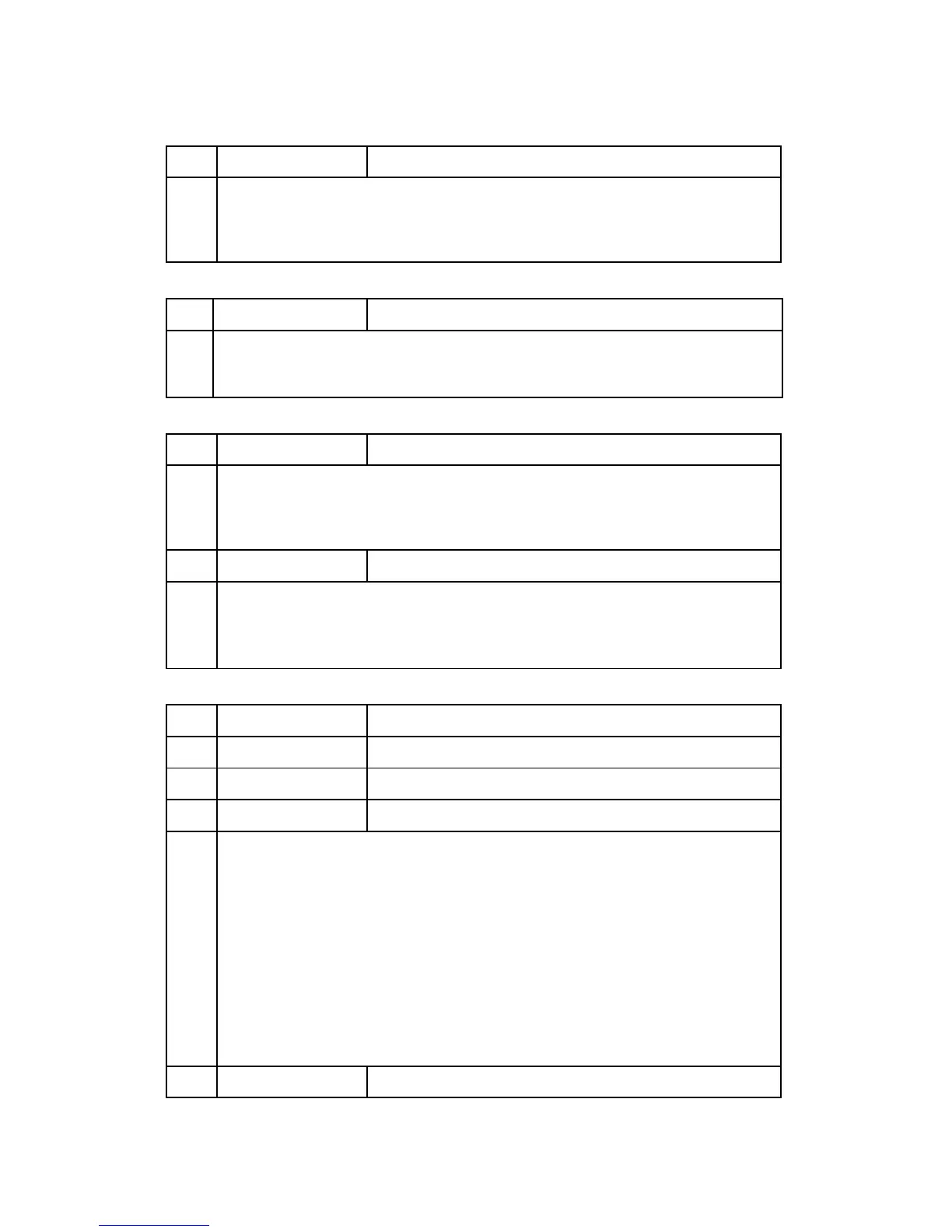

Charge Width Setting Mj1: Simplex

1100 CHG:W1:EDGE:1 LE/TE: Mj1:ID1

1102 CHG:W1:EDGE:2 LE/TE: Mj1:ID2

1104 CHG:W1:EDGE:3 LE/TE: Mj1:ID3

1106 CHG:W1:EDGE:4 LE/TE: Mj1:ID4

Use this SP to set the pitch width of the charge applied to the LE/TE of normal

paper for printing in the High Speed (Draft) mode. Do this SP when mist build-up

near the leading and trailing edges of the paper in use during printing in the High

Speed (Draft) mode is clogging the print head nozzles. This SP setting is linked

to the charge pitch tables (SP1200 to SP1231).

The IDs are determined by the temperature and humidity. There are 4 IDs

associated with the SP numbers listed below:

SP1100:ID1

SP1102:ID2

SP1104:ID3

SP1106:ID4

[0 to 255/0/1/0.1 mm]

1101 CHG:W1:MID:1 MID: Mj1:ID1

Loading...

Loading...