PGM-FI SYSTEM

ECTSE

3.

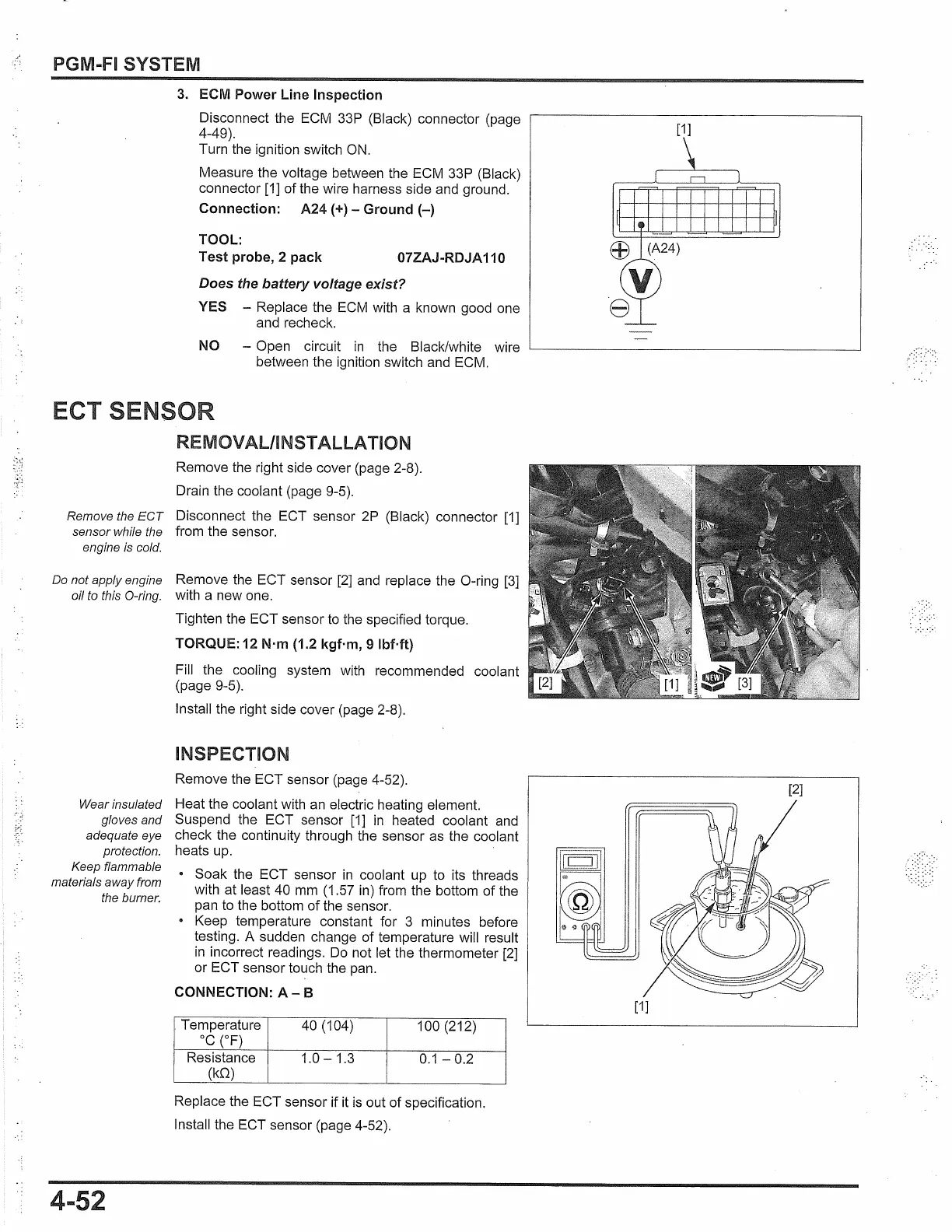

ECM Power Line Inspection

Disconnect the ECM 33P (Black) connector (page

4-49).

Turn the ignition switch

ON.

Measure the voltage between the ECM 33P (Black)

connector [1] of the wire harness side and ground.

Connection: A24

(+) -

Ground

(-)

TOOL:

Test probe,

2

pack

07ZAJ-RDJA

110

Does the battery voltage exist?

YES - Replace the ECM with a known good one

and recheck.

NO - Open circuit

in

the Black/white wire

between the ignition switch and ECM.

REMOVAL/INSTALLATION

Remove the right side cover (page 2-8).

Drain the coolant (page 9-5).

Remove the

ECT

Disconnect the ECT sensor 2P (Black) connector [1]

sensor while the

from the sensor.

engine is cold.

Do not apply engine

Remove the ECT sensor

[2]

and replace the 0-ring

[3]

oil to this 0-ring.

with a new one.

Wear insulated

gloves and

adequate eye

protection.

Keep flammable

materials away from

the burner.

4-52

Tighten the ECT sensor

to

the specified torque.

TORQUE:

12 N·m (1.2 kgf·m, 9

lbMt)

Fill the cooling system with recommended coolant

(page 9-5).

Install the right side cover (page 2-8).

INSPECTION

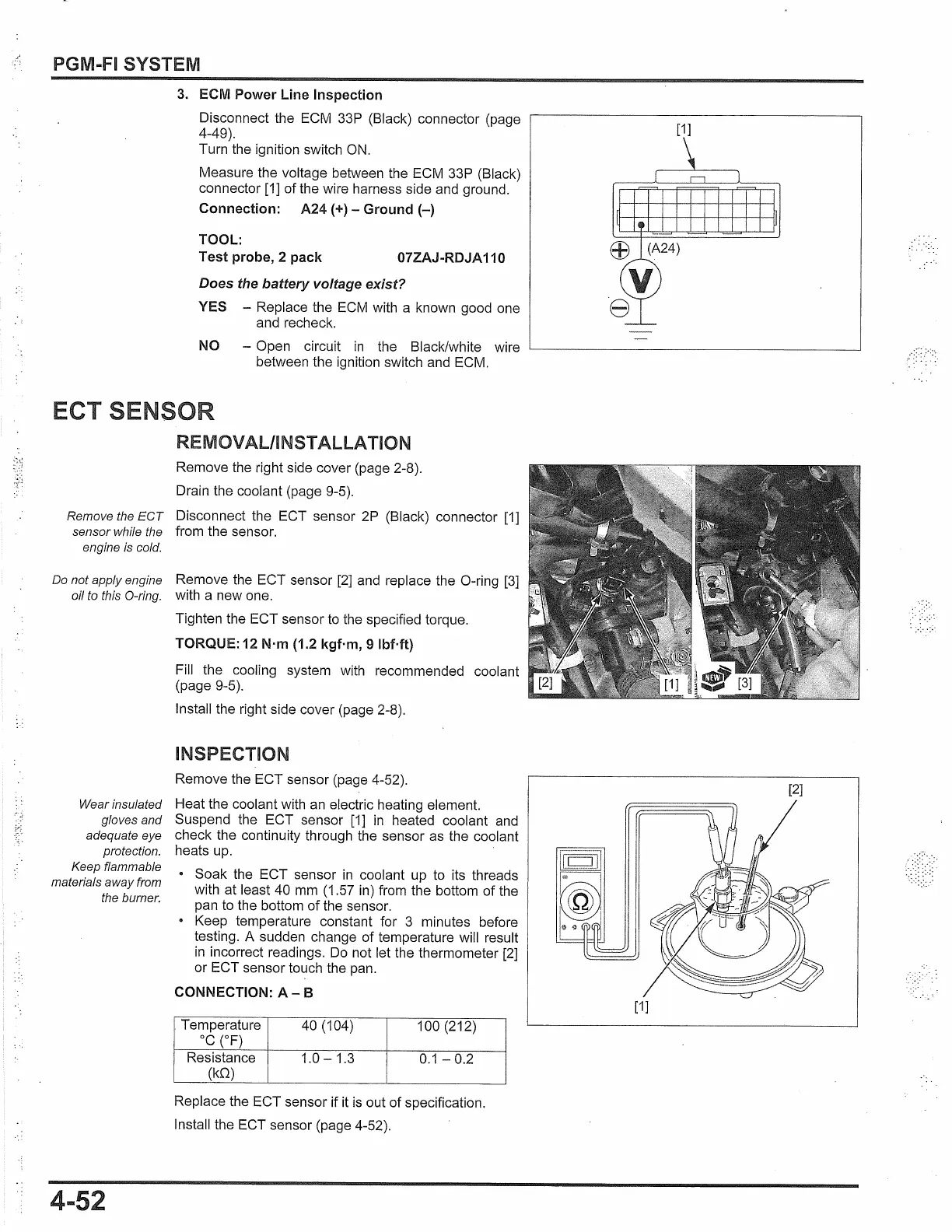

Remove the ECT sensor (page 4-52).

Heat the coolant with an electric heating element.

Suspend the ECT sensor

[1]

in

heated coolant and

check the continuity through the sensor as the coolant

heats up.

Soak the ECT sensor

in

coolant up to its threads

with at least 40 mm (1.57 in) from the bottom of the

pan to the bottom

of

the sensor.

• Keep temperature constant for 3 minutes before

testing. A sudden change of temperature will result

in

incorrect readings.

Do

not let the thermometer

[2]

or ECT sensor touch the pan.

CONNECTION:

A-

B

Temperature

40 (104) 100 (212)

oc

(OF)

Resistance

1.0 - 1.3

0.1

-0.2

(kQ)

Replace the ECT sensor if

it

is

out of specification.

Install the ECT sensor (page 4-52).

[1]

[2]

[1]

Loading...

Loading...