.

:-····

Disassemble the cylinder head (page 10-14).

Chill new valve guides

in

a freezer for about 1 hour.

NOTE:

•

Be

sure

to

wear heavy gloves to avoid burns when

handling the heated cylinder head.

• Using a torch

to

heat the cylinder head may cause

warpage.

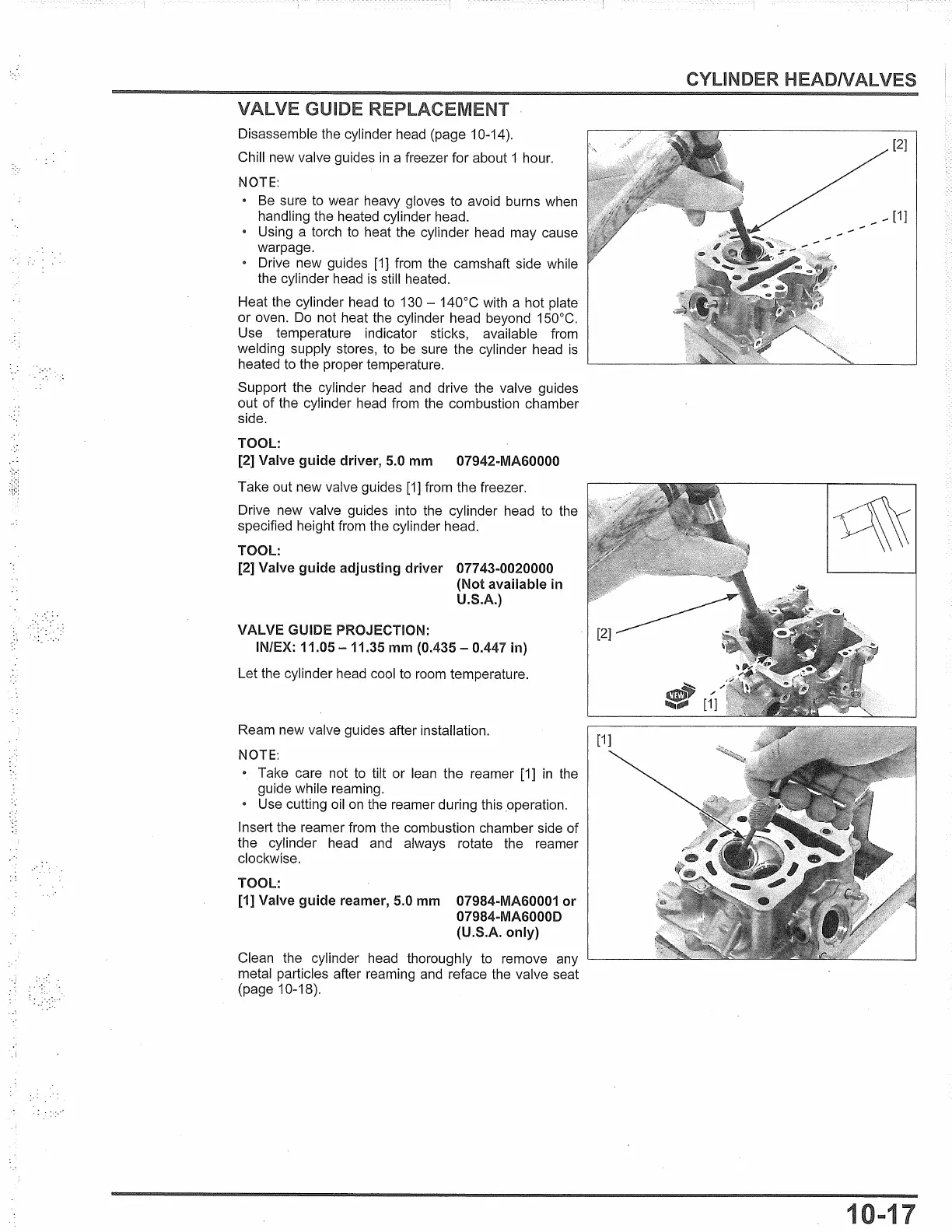

Drive new guides

[1]

from the camshaft side while

the cylinder head

is

still heated.

Heat the cylinder head

to

130 - 140°C with a hot plate

or oven.

Do

not heat the cylinder head beyond 150°C.

Use temperature indicator sticks, available from

welding supply stores,

to

be

sure the cylinder head

is

heated to the proper temperature.

Support the cylinder head

and

drive the valve guides

out of the cylinder head from the combustion chamber

side.

TOOL:

[2]

Valve guide driver, 5.0

mm

07942-MAGOOOO

Take out new valve guides

[1]

from the freezer.

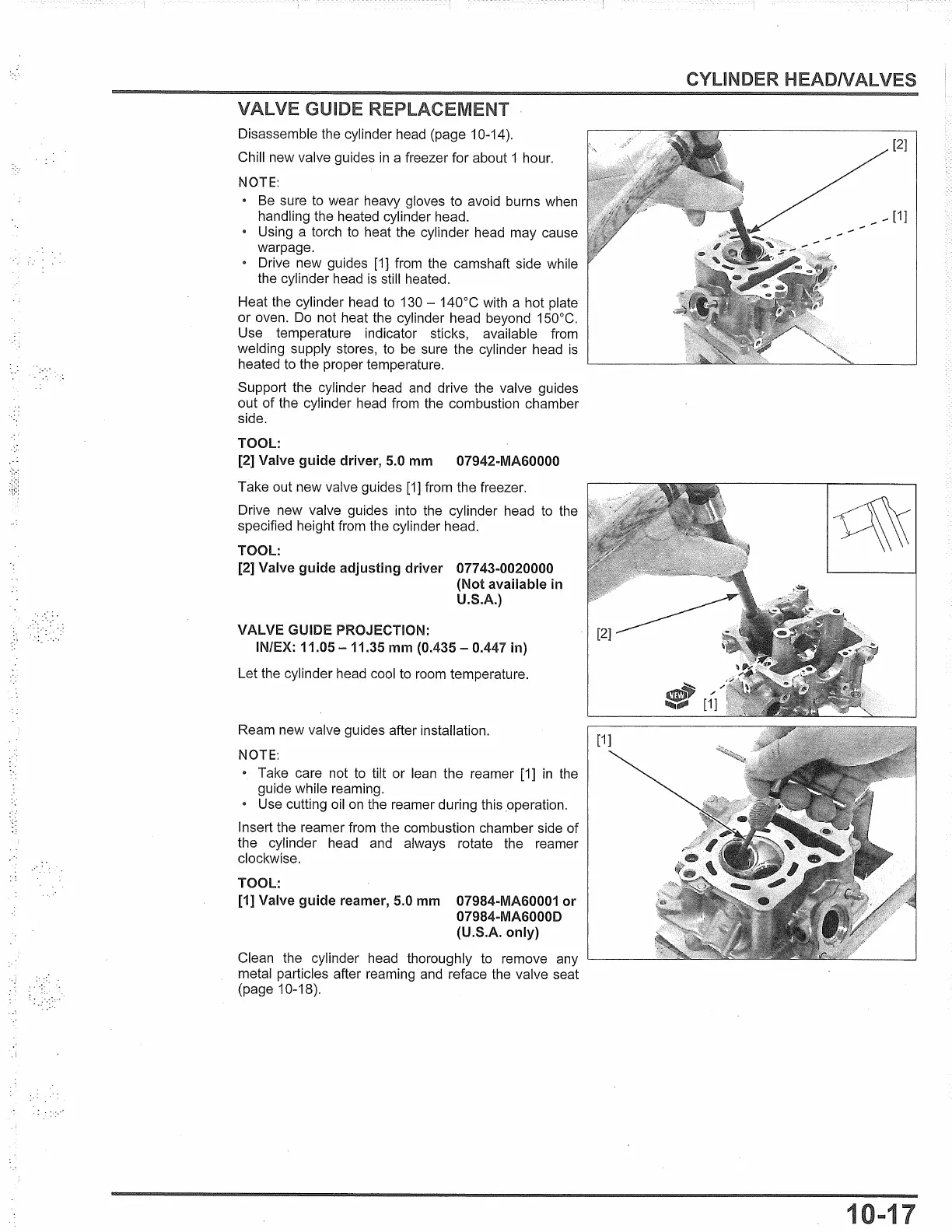

Drive new valve guides into the cylinder head

to

the

specified height from the cylinder head.

TOOL:

[2] Valve guide adjusting driver 07743-0020000

(Not available

in

U.S.A.)

VALVE GUIDE PROJECTION:

IN/EX: 11.05 - 11.35

mm

(0.435 - 0.447 in)

Let the cylinder head cool to

room

temperature.

Ream new valve guides after installation.

NOTE:

• Take care not

to

tilt or lean the reamer [1]

in

the

guide while reaming.

• Use cutting

oil

on

the reamer during this operation.

Insert the reamer from the combustion chamber side of

the cylinder head

and

always rotate the reamer

clockwise.

TOOL:

[1] Valve guide reamer, 5.0

mm

07984-MA60001 or

07984-MA6000D

(U.S.A. only)

Clean the cylinder head thoroughly

to

remove any

metal particles after reaming

and

reface the valve seat

(page 10-18) .

CYLINDER HEADNALVES

[2]

1

Loading...

Loading...