CYLINDER/PISTON

11-8

INSPECTION

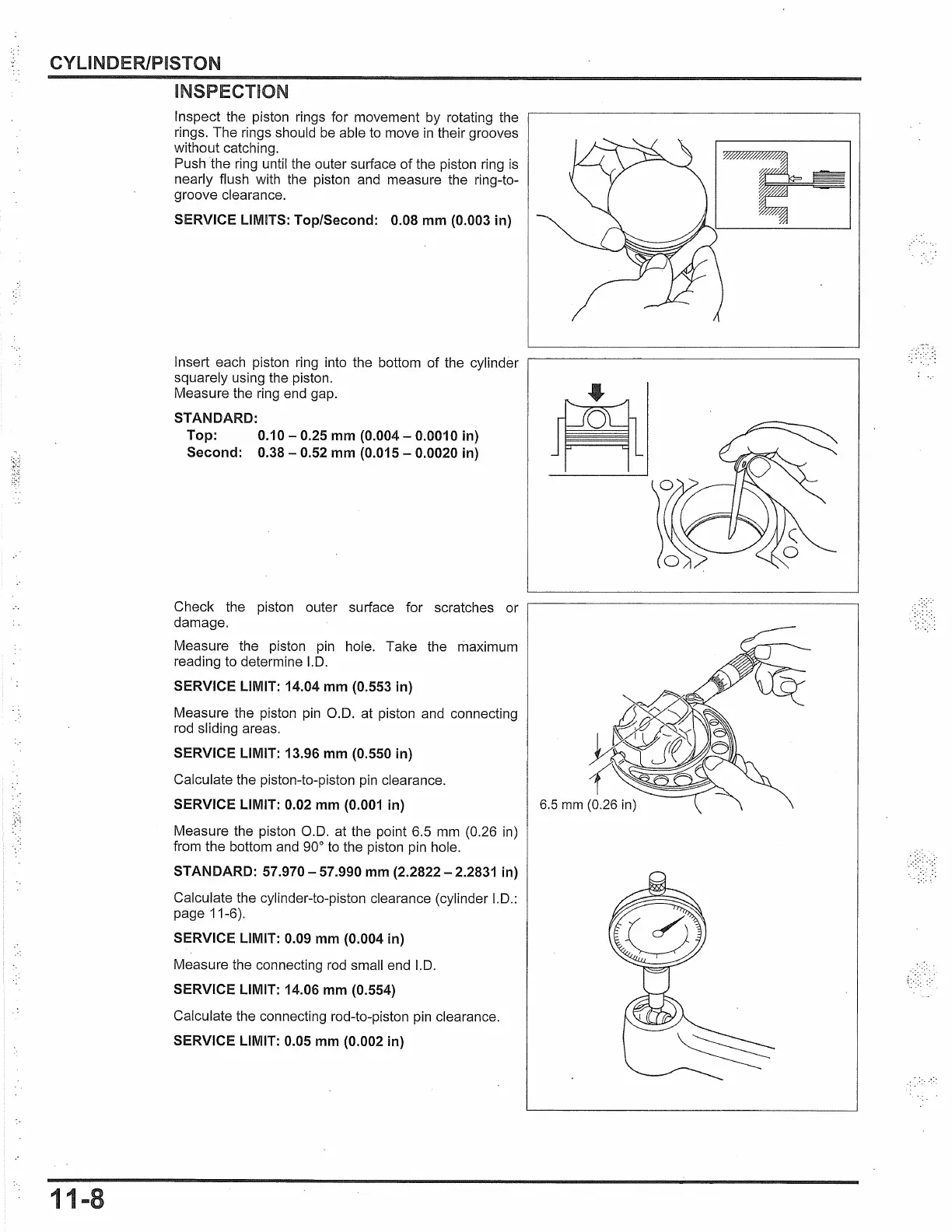

Inspect the piston rings for movement by rotating the

rings. The rings should

be

able

to

move

in

their grooves

without catching.

Push the ring until the outer surface

of

the piston ring

is

nearly flush with the piston and measure the ring-to-

groove clearance.

SERVICE LIMITS: Top/Second: 0.08

mm

(0.003 in)

Insert each piston ring into the bottom of the cylinder

squarely using the piston.

Measure the ring end gap.

STANDARD:

Top: 0.10 - 0.25

mm

(0.004-

0.0010 in)

Second: 0.38 - 0.52

mm

(0.015 - 0.0020 in)

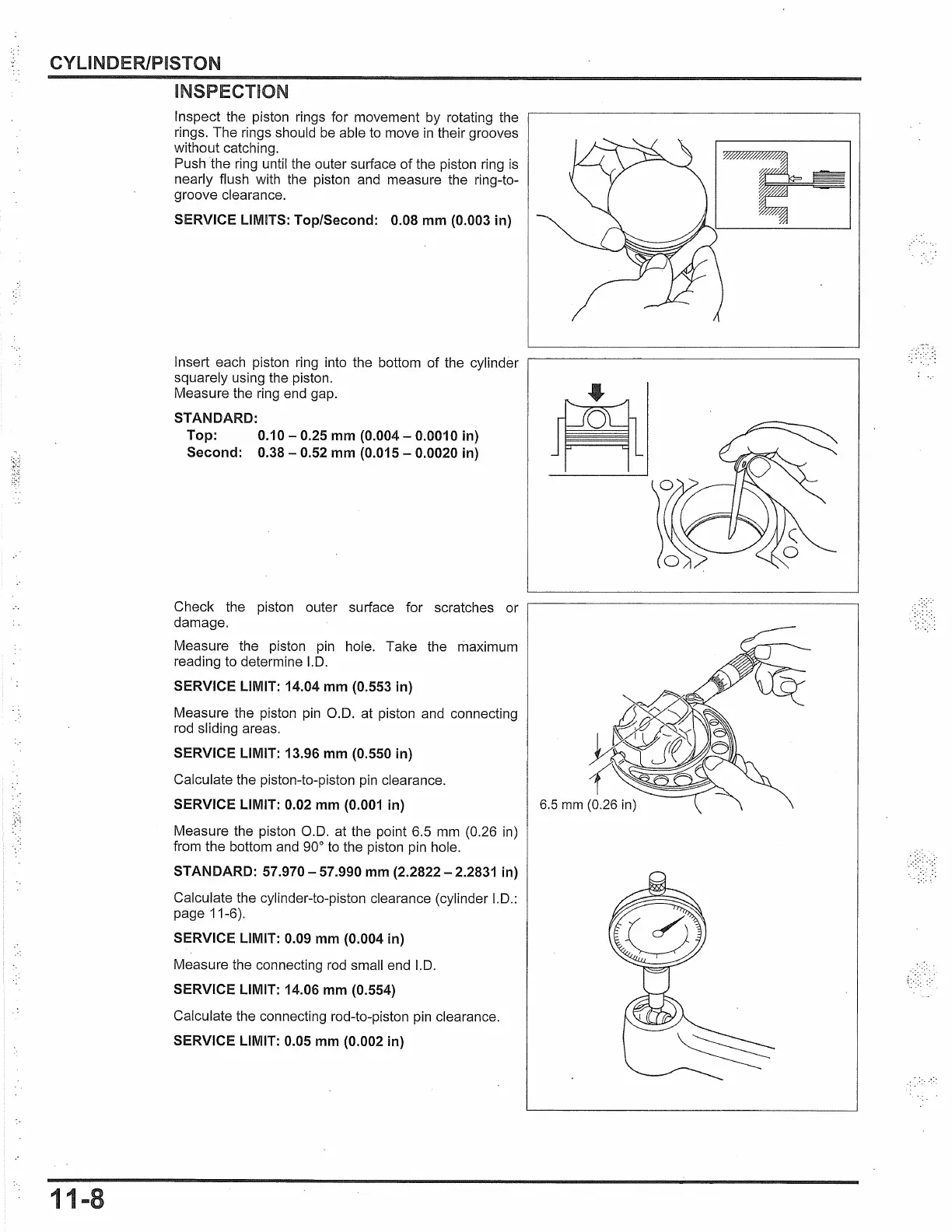

Check the piston outer surface for scratches or

damage.

Measure the piston

pin

hole. Take the maximum

reading to determine

1.0.

SERVICE LIMIT: 14.04

mm

(0.553 in)

Measure the piston

pin

0.0.

at piston and connecting

rod

sliding areas.

SERVICE LIMIT: 13.96

mm

(0.550 in)

Calculate the piston-to-piston

pin

clearance.

SERVICE LIMIT: 0.02

mm

(0.001 in)

Measure the piston

0.0.

at the point

6.5

mm

(0.26

in)

from the bottom

and

90°

to

the piston pin hole.

STANDARD:

57.970-57.990

mm

(2.2822-2.2831

in)

Calculate the cylinder-to-piston clearance (cylinder

1.0.:

page 11-6).

SERVICE LIMIT: 0.09

mm

(0.004 in)

Measure the connecting

rod

small end

1.0.

SERVICE LIMIT: 14.06

mm

(0.554)

Calculate the connecting rod-to-piston

pin

clearance.

SERVICE LIMIT: 0.05

mm

(0.002 in)

Loading...

Loading...