3

© 2012 TOSHIBA TEC CORPORATION All rights reserved e-STUDIO556/656/756/856(Ver03)

OUTLINE OF THE MACHINE

3 - 83

3.15.3 Functions

(1) Cleaning web

The cleaning web is attached touching the fuser roller by means of the web pushing roller to

remove any toner or paper dust that has stuck to the fuser roller during the fusing process. It is

rolled up by the web motor (M4) with its clean surface always touching the fuser roller. It also

contains silicone oil for coating the surface of the fuser roller, which makes it easier to clean up

any toner or paper dust.

The cleaning web rolled around the roller has been made thinner and lengthened. This has

increased the web rolling up speed and improved the cleaning performance. The cleaning web's

cleaning performance is the same as that of the cleaning roller, so this equipment does not have

a cleaning roller.

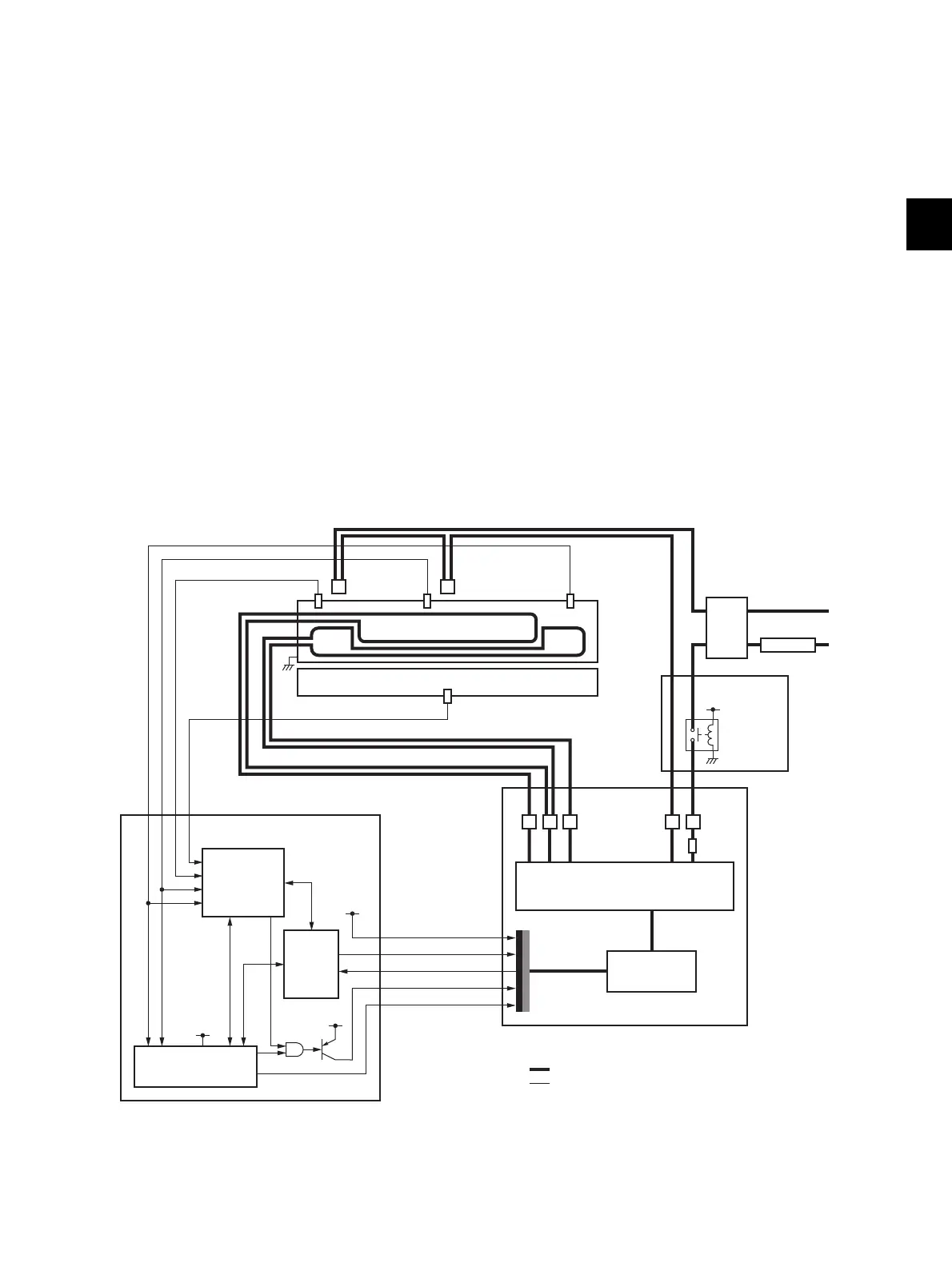

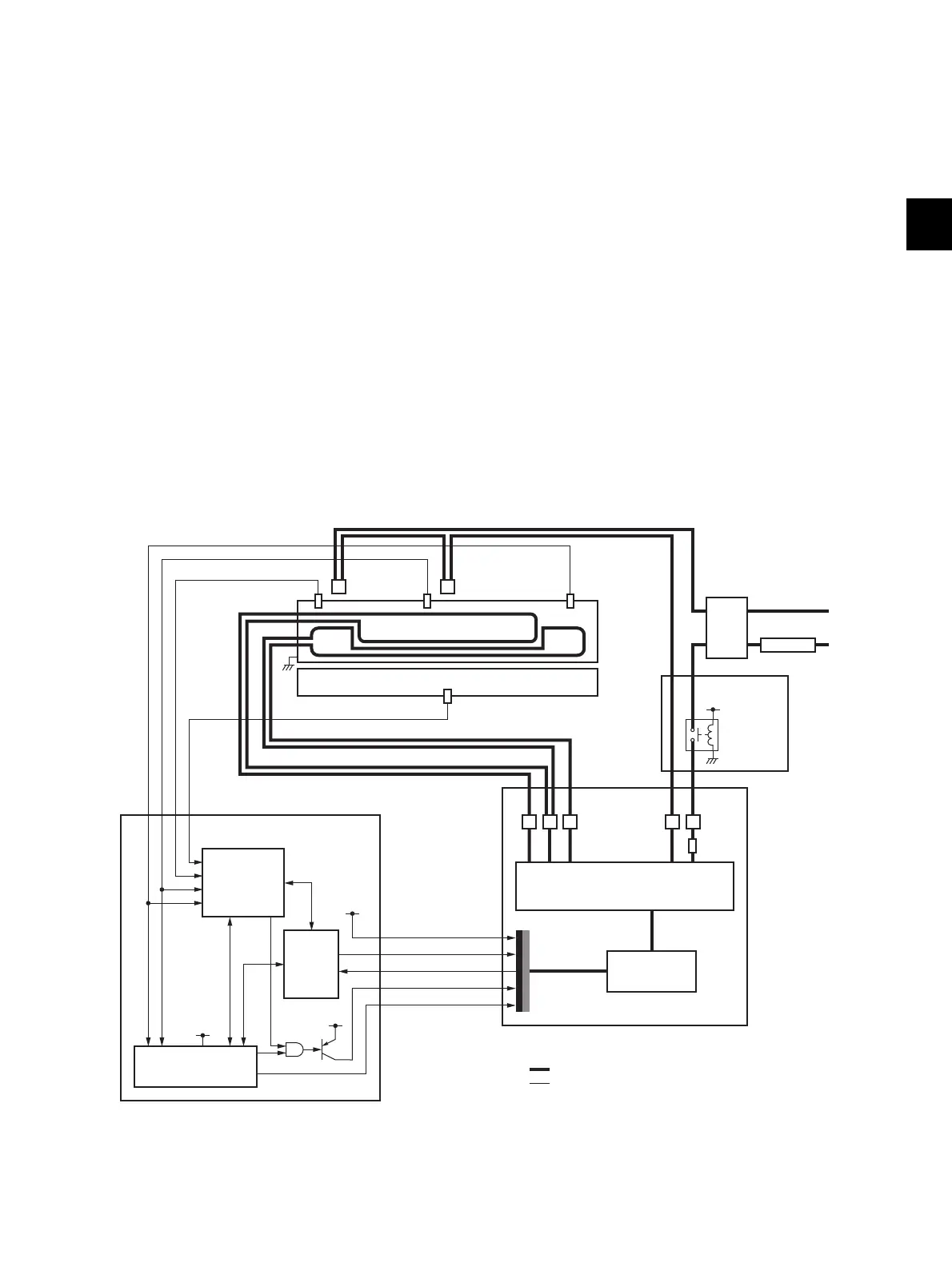

3.15.4 Fuser Control Circuit

[ 1 ] Configuration

A forcible power OFF circuit is embedded in this equipment. This circuit detects the overheating of the

fuser unit with the thermistors installed on it. When the surface temperature of either the fuser roller or

the pressure roller has exceeded the specified value, the circuit sends the relay ON signal in order to

shut off the power supply throughout the unit.

Fig. 3-50

N L

IH board

LGC board

+5VB

+5VSW

Temperature

control circuit

Coil output

Fuse

AC input

Noise

filter

Breaker

Power cable

IH power source / drive circuit

Control circuit

including CPU

Photocoupler

AC line

DC line

Power supply for photocoupler

Switching signal of power setting

Duty ratio changing signal

IH status signal

IH coil energization permitting signal

Engine CPU

ASIC

IH coil

Fuser roller

Pressure

roller

Center

thermistor

Center thermostatSide thermostat

Rear thermistor

Front thermistor

Pressure roller thermistor

Switching regulator

+5VSW

Relay

+5VSW

Loading...

Loading...