e-STUDIO556/656/756/856(Ver03) © 2012 TOSHIBA TEC CORPORATION All rights reserved

OUTLINE OF THE MACHINE

3 - 38

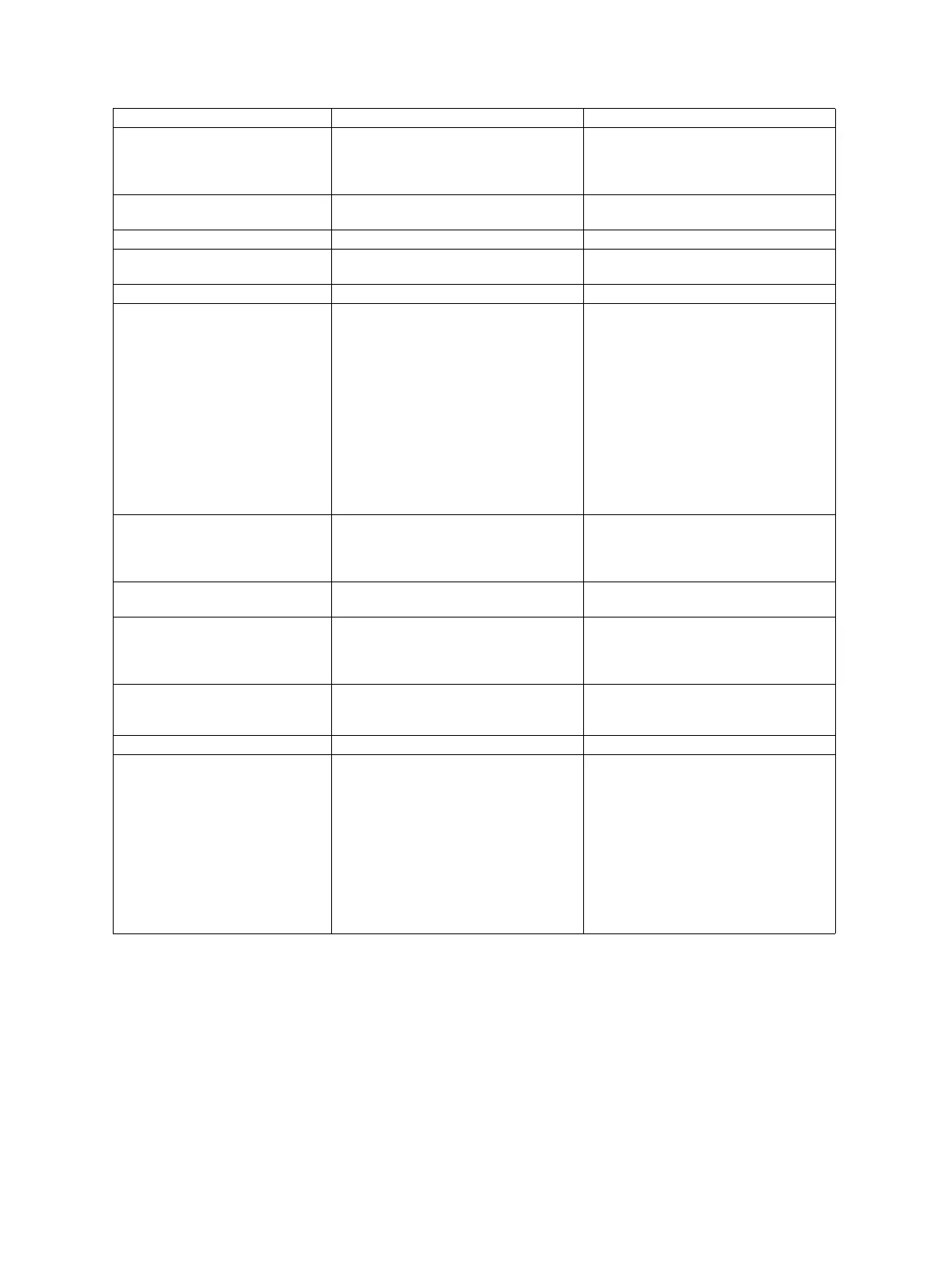

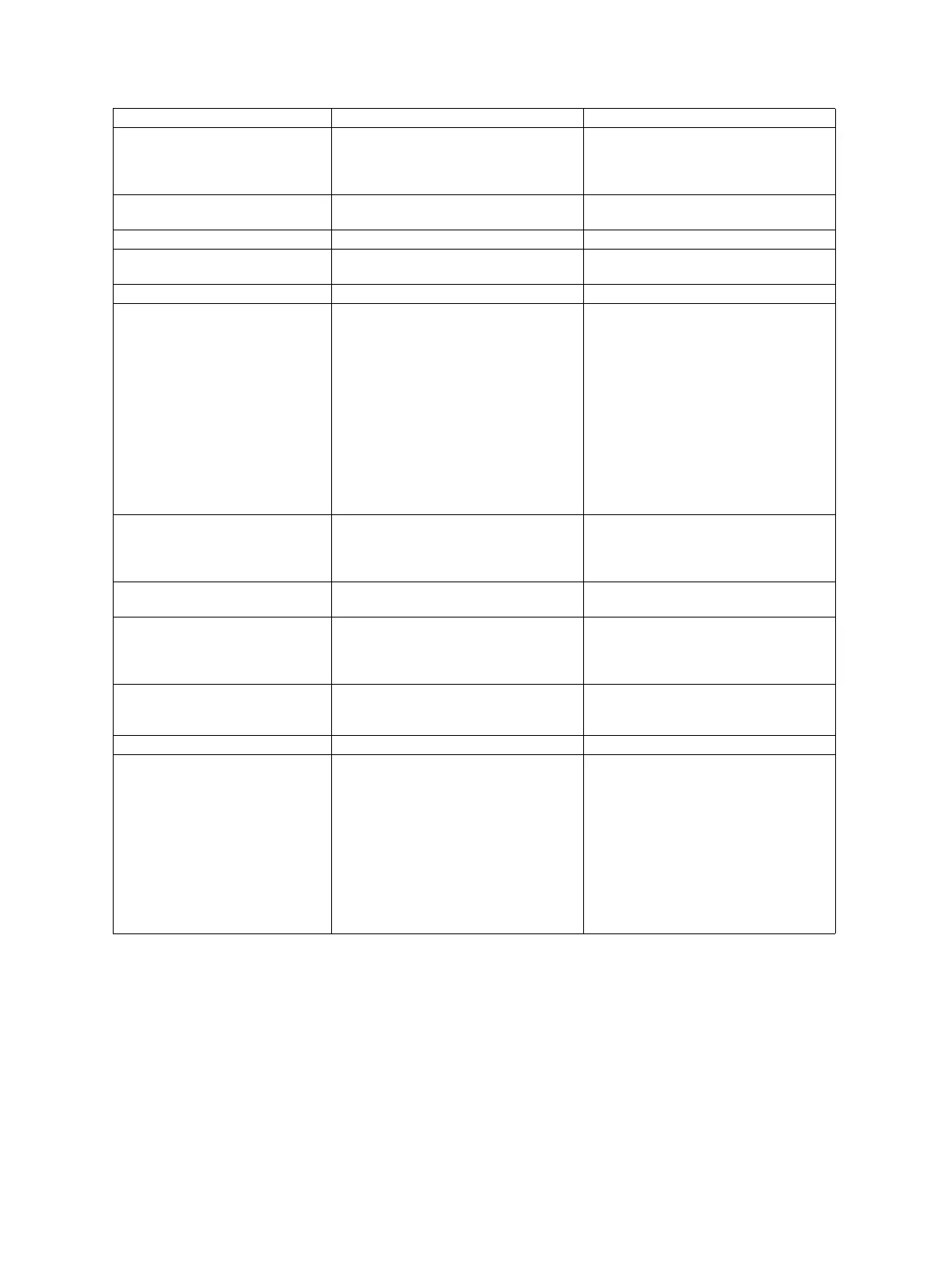

3.5 Comparison of Copy Process to e-STUDIO555/655/755/855

Process e-STUDIO555/655/755/855 e-STUDIO556/656/756/856

1. Photoconductive drum

• Sensitivity

• Surface potential

OD-6510 (OPC drum)

Highly sensitized drum

-490 V (-290 to -890 V)

Grid voltage -500 V (-300 to -900 V)

←

←

←

←

2. Charging Scolotron method (constant current)

Grid output variable

←

←

3. Surface potential controlling Surface potential sensor ←

4. Writing

• Light source Semiconductor laser ←

5. Image density control Image quality sensor ←

6. Development

• Magnetic roller

• Auto-toner

• Toner supply

• Toner-empty detection

• Toner

• Developer material

• Developer bias

Two magnetic rollers

Magnetic bridge-circuit method

Toner cartridge system

(There is a toner recycle system.)

Density detection system

(There is a toner cartridge empty

detecting system by piezoelectric

type sensor.)

PS-ZT8550/PS-ZT8550E/

PS-ZT6000D/PS-ZT6000C

PS-ZD6000

-394 V (-200 to -800 V) DC + AC

←

←

←

←

←

←

←

PS-ZT8560/PS-ZT8560E/

←

←

←

7. Transfer

• Transfer

• Power supply roller

Separation auxiliary roller

Transfer belt

Power supply roller

none

←

←

←

8. Separation Transfer belt charging

Separation finger applied

←

←

9. Discharging

• Discharging position

• Discharge lamp

• Pre-cleaning discharge

Discharge by exposure after cleaning

Discharge by red LED

None

←

←

←

10. Cleaning

• System

• Recovered toner

Blade + Brush

Reuse (by the toner recycle system)

←

←

11. Cleaning brush bias Varistor 430V ←

12. Fusing

• System

• Cleaning

•Heater

Long-life heat roller system

Fuser roller: Fluoroplastic-coated

roller (ø60)

Pressure roller: PFA tube roller (ø60)

Cleaning web

(for fuser roller cleaning)

IH coil (Induction heating system)

ON/OFF control by thermistor

←

←

←

←

←

Loading...

Loading...