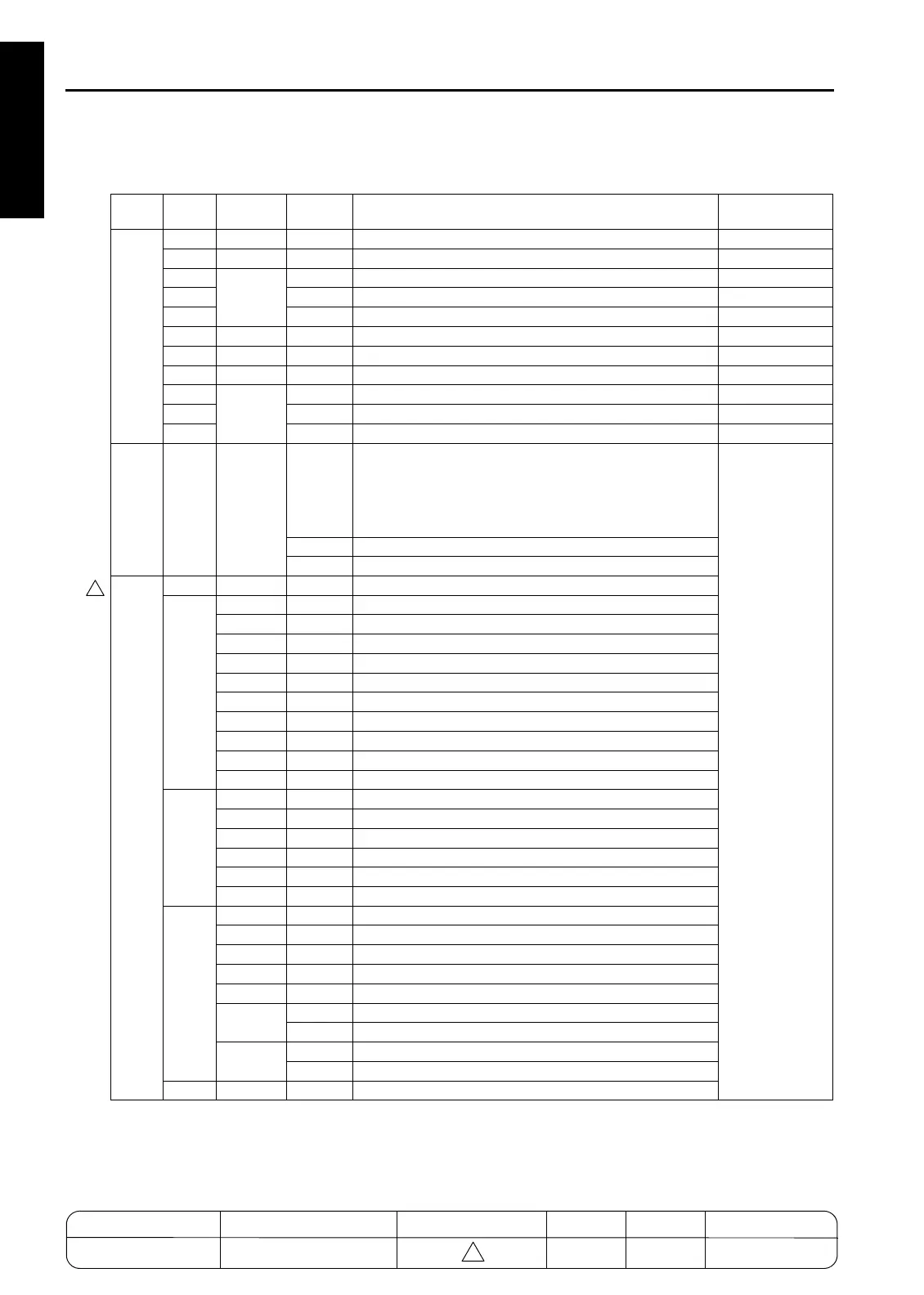

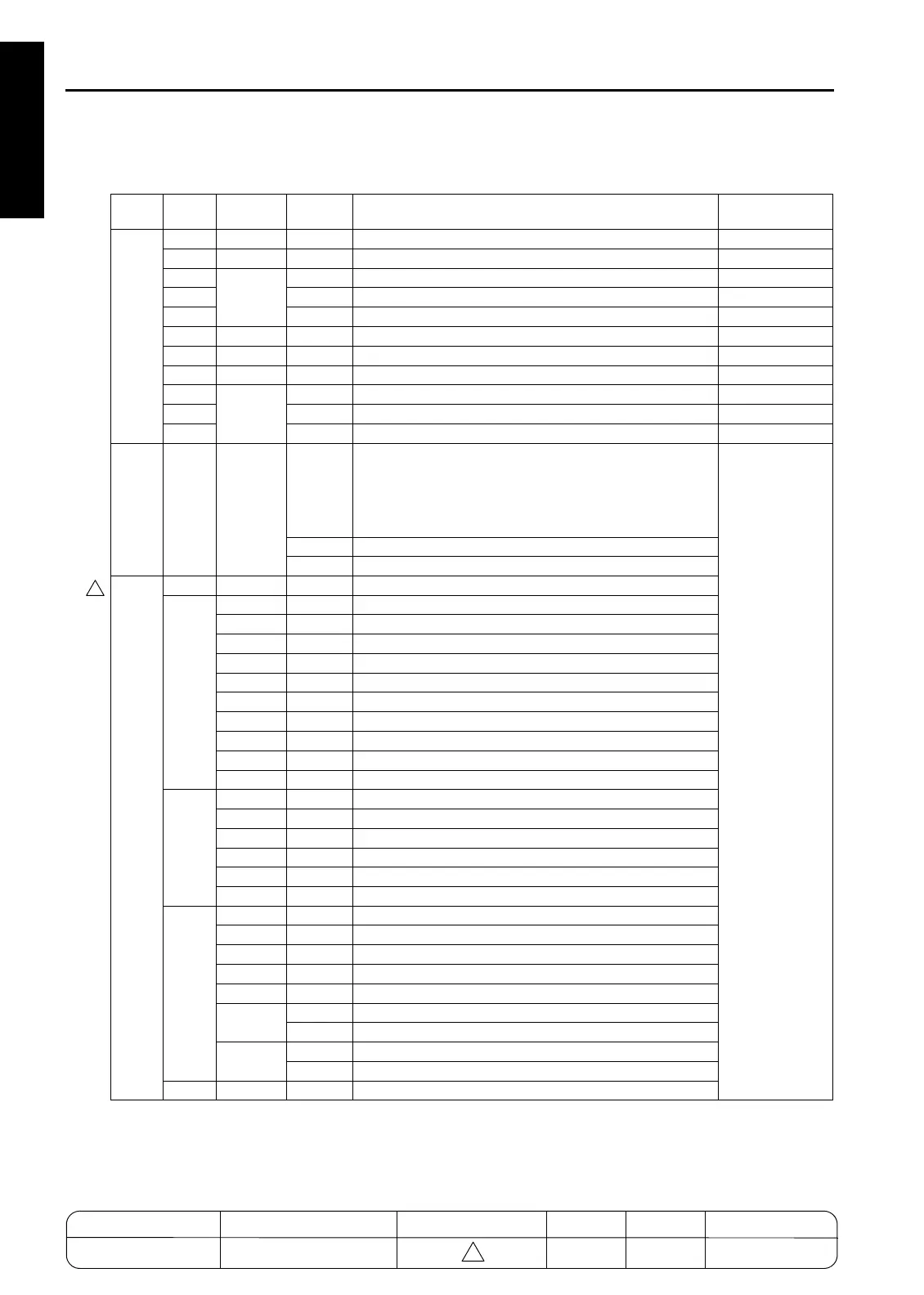

47 MODE

1 ADJUSTMENT

[5] Output checklist

Classi-

fication

Code Symbol

Multi

mode

Name

Cannot be set or

changed in field

Analog signal

000 L1

*1 Exposure lamp

001 M13

Toner bottle motor

002

HV

Charger

×

003

Transfer

×

004

Separation (AC+DC)

×

005

D max LED

×

006

γ

LED

×

007

Jam detection LED

×

008

HV

Transfer access guide plate

×

009

Bias

010

Toner guide roller

×

KRDS

015

1

Process adjustment related:

Clear the following data from main body and KRDS:

Copy count by size, ADF passage count, JAM count,

optional parts count, fixed parts count, count by mode, SC

count, JAM data of time series (including pointer)

2

Job memory clear

98

KRDS initialization

Paper feed

020 SD100

LCT paper feed pickup SD

021

Feed MC

MC3 1

Tray 1

MC5 2

Tray 2

MC7 3

Tray 3

MC9 4

Tray 4

MC101 5

LCT

MC11 6

Vertical conveyance CL1

MC12 7

Vertical conveyance CL2

MC15 8

Horizontal conveyance CL/L (7255/7272 only)

MC16 9

Horizontal conveyance CL/R (7255/7272 only)

022

Pre-registration CL

MC4 1

Tray 1

MC6 2

Tray 2

MC8 3

Tray 3

MC10 4

Tray 4

MC102 5

LCT

023

Tray up motor /LCT UP/DOWN motor

M16 1

Tray 1

M17 2

Tray 2

M18 3

Tray 3

M19 4

Tray 4

M100

5

LCT up

6

LCT down

M20

7

By-pass up

8

By-pass down

025 MC1

Registration MC

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE MANUAL Dec. 2003

7155/7165/7255/7272

1-92 REPLACEMENT

4

4

Loading...

Loading...