OTHER ADJUSTMENT

1 ADJUSTMENT

[5] Skew adjustment (LT-402/LT-412

only)

Caution: Skew adjustment is required when the

paper supplied from the current tray is

different from the paper supplied from

other trays in the way it is skewed.

However, this adjustment has little

effect because skew of paper supplied

from all trays is corrected in the sec-

ond paper feed unit.

1. Tool

• Screwdriver (Phillips)

2. LCT skew adjustment

a. Adjustment method (when all printed sheets are

skewed)

b. Adjustment method (when some printed sheets

are skewed irregularly)

Reference: The indicated size of each guide

plate is about 2mm wider than the

size of regular paper. The 2mm gap

may cause paper skew depending

on the paper type. To reduce this

skew, press the guide plates (front

and rear) against paper tightly.

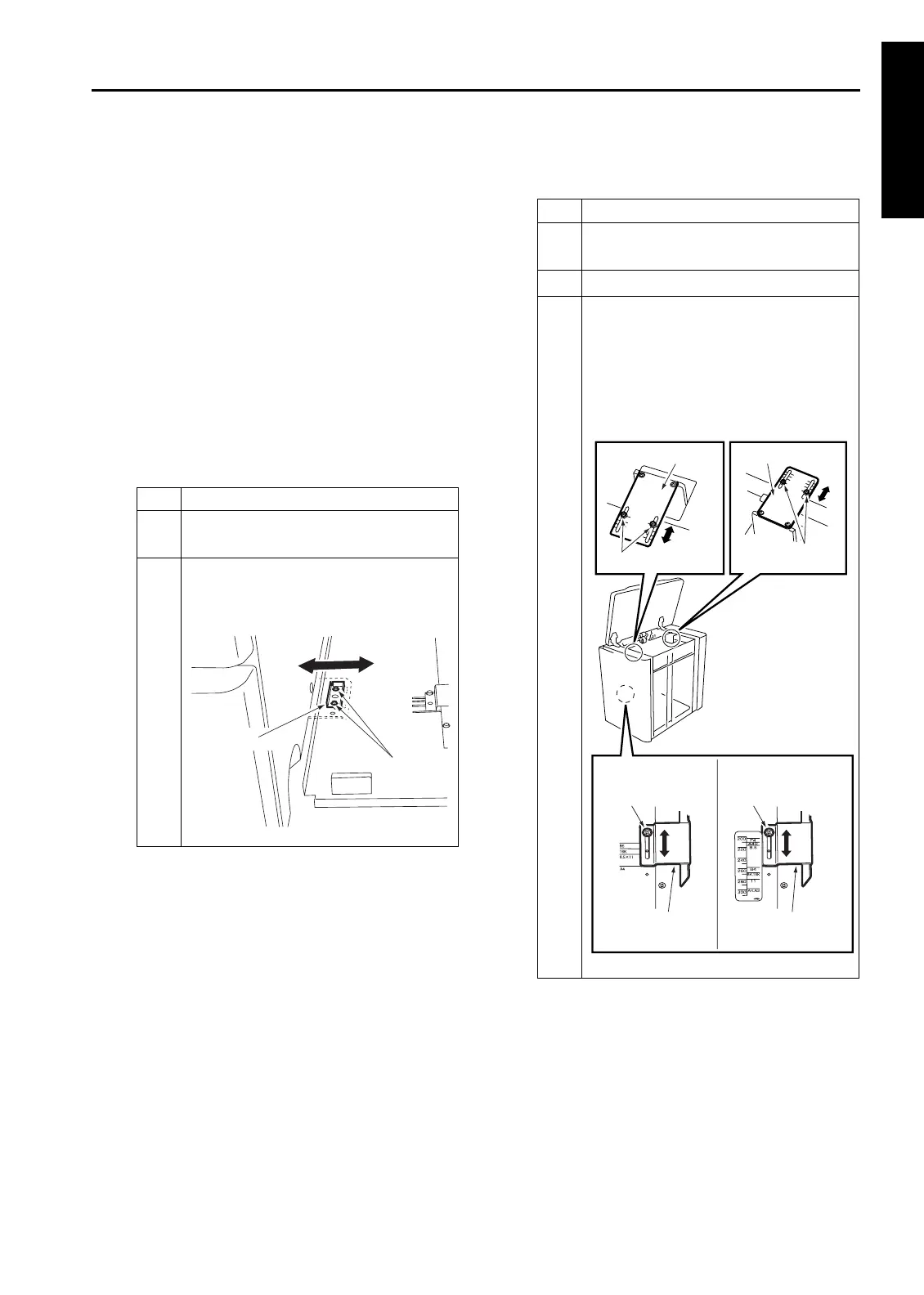

Step Operation

1

Print a test pattern (No.16) in the contin-

uous copy mode to check for skew.

2

Open the jam access door of the LCT

and adjust the installation position of the

positioning bracket on the bottom plate.

Positioning

bracket

Screws

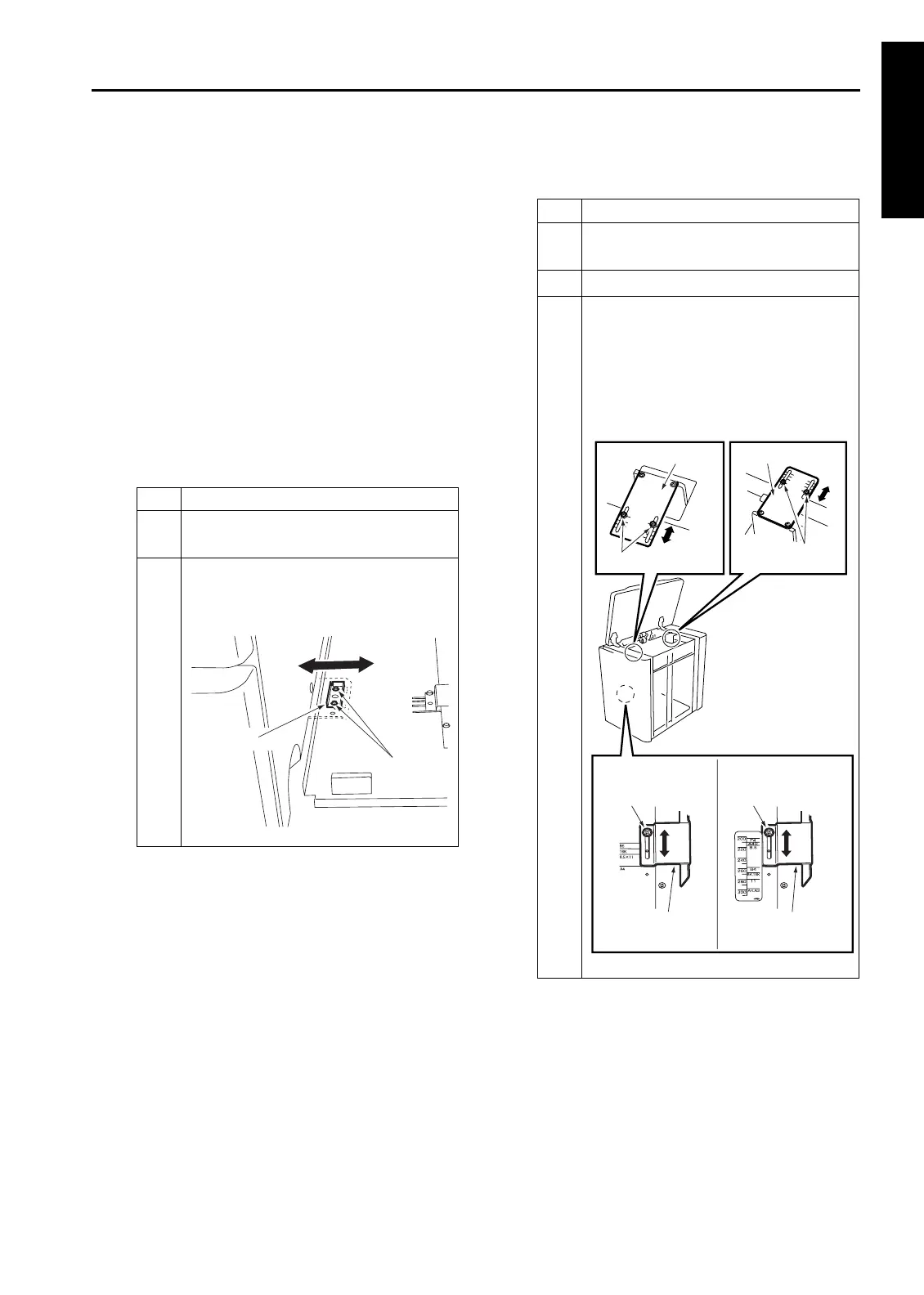

Step Operation

1

Print a test pattern (No.16) in the contin-

uous copy mode to check for skew.

2

Remove the side cover (right).

3

Loosen the five screws securing the

guide plates (front and rear) and the cen-

tering positioning bracket temporarily.

Press the guide plates (front and rear)

against paper, then tighten the five

screws.

LT-412LT-402

Guide plate (front)

Guide plate (rear)

Centering

positioning bracket

Centering

positioning bracket

Screws

Screws

1-103

Loading...

Loading...