DRIVE SECTION

2-B-1

2 UNIT EXPLANATION

DRIVE SECTION

[1] Composition

[2] Mechanisms

*1 Independent drive mechanisms

Drive mechanisms of this machine are driven by

dedicated motors to ensure high-speed opera-

tion and to improve serviceability of the drum unit

and developing performance.

Speeds of the drum motor (M2), fixing motor

(M4), and loop roller motor (M6) are switched as

shown below according to the paper type

selected in the key operator mode, thus enhanc-

ing reliability of copying on thick paper.

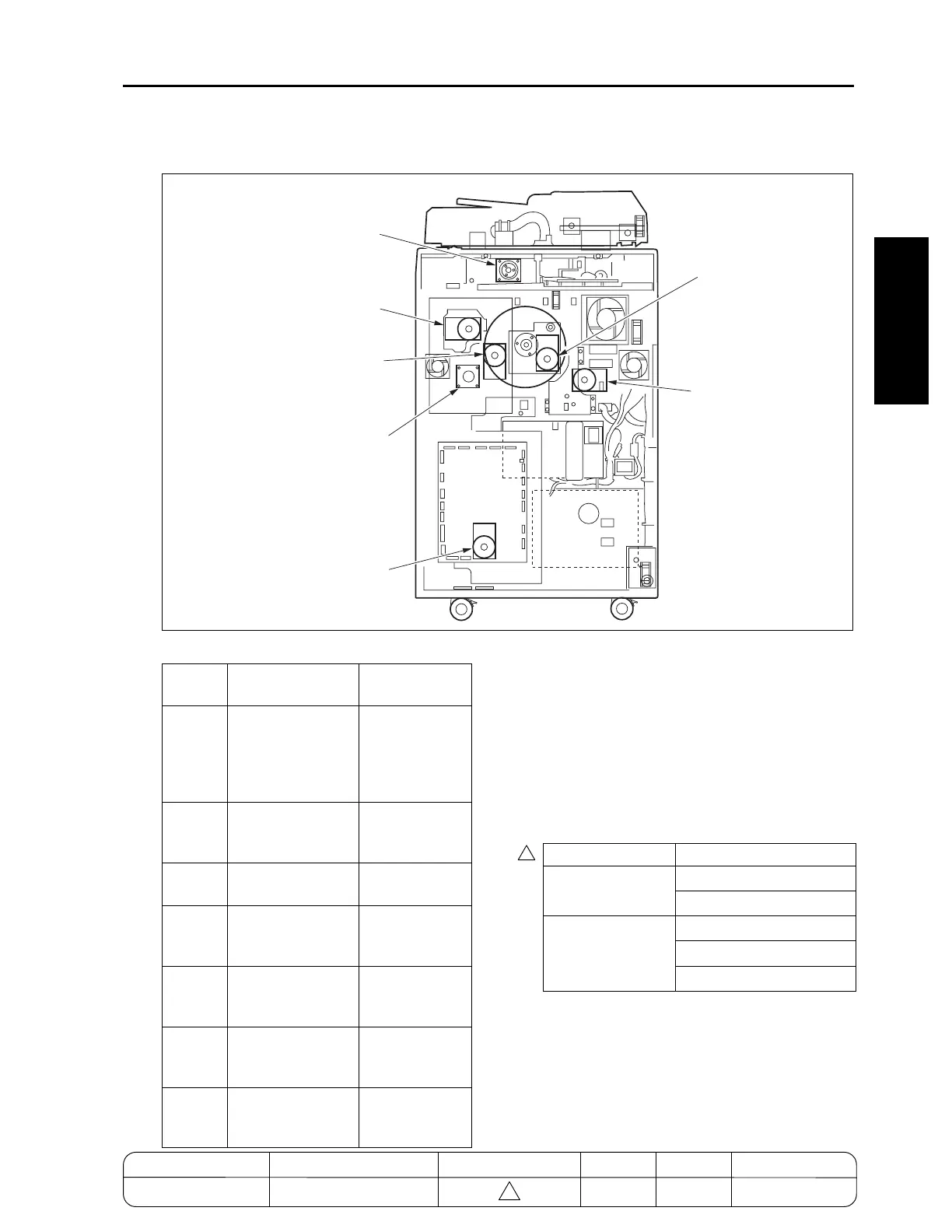

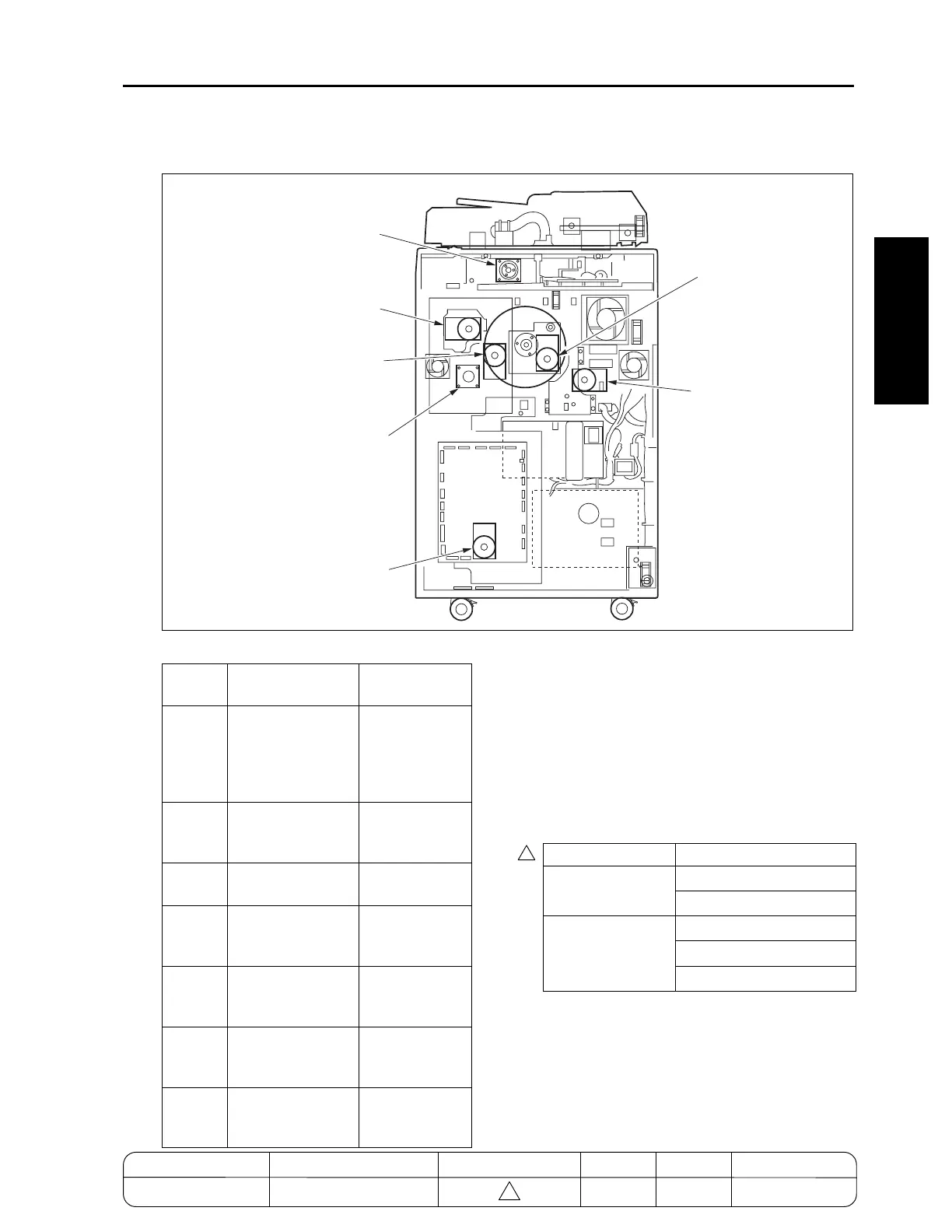

7272ma2002

Scanner motor (M11)

Toner bottle motor (M13)

Drum motor (M2)

Loop roller motor (M6)

Developing motor (M3)

Fixing motor (M4)

Paper feed motor (M1)

Mecha-

nism

Driven Parts Method

Drum

drive*1

Drum, Toner guide

roller, Toner con-

veyance screw, and

Separation claw

swing

Gear drive (ded-

icated motor)

Develop-

ing

drive*1

Developing sleeve Gear drive (ded-

icated motor)

Fixing

drive*1

Fixing roller (upper) Gear drive (ded-

icated motor)

Paper

feed

drive*1

Tray 1/2/3, Vertical

conveyance roller

(middle/lower)

Gear drive (ded-

icated motor) +

Belt

By-pass/

loop

drive*1

By-pass feed roller

and ADU pre-regis-

tration roller

Gear drive (ded-

icated motor) +

Belt

Scanner

drive*1

Exposure unit, V-

mirror unit

Wire drive (dedi-

cated motor )+

Belt

Paper

exit

drive*1

Paper exit roller Gear drive (ded-

icated motor)

Paper type Motor speed

Thick paper 185 mm/s (7155/7165)

172.5mm/s (7255/7272)

Others 280 mm/s (7155/7255)

320 mm/s (7165)

345 mm/s (7272)

4

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE MANUAL Dec. 2003

7155/7165/7255/7272

2-B-1 REPLACEMENT

4

Loading...

Loading...