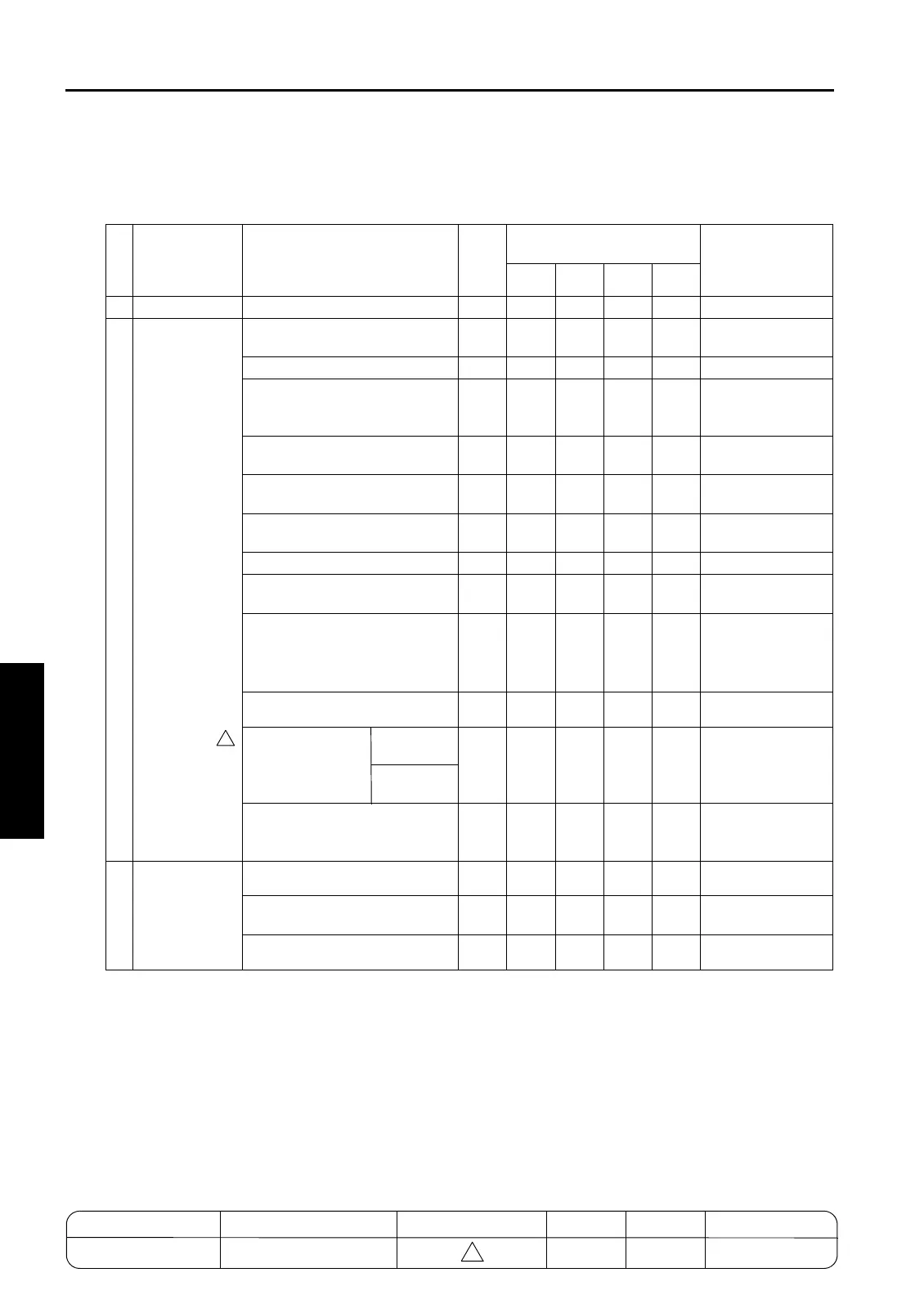

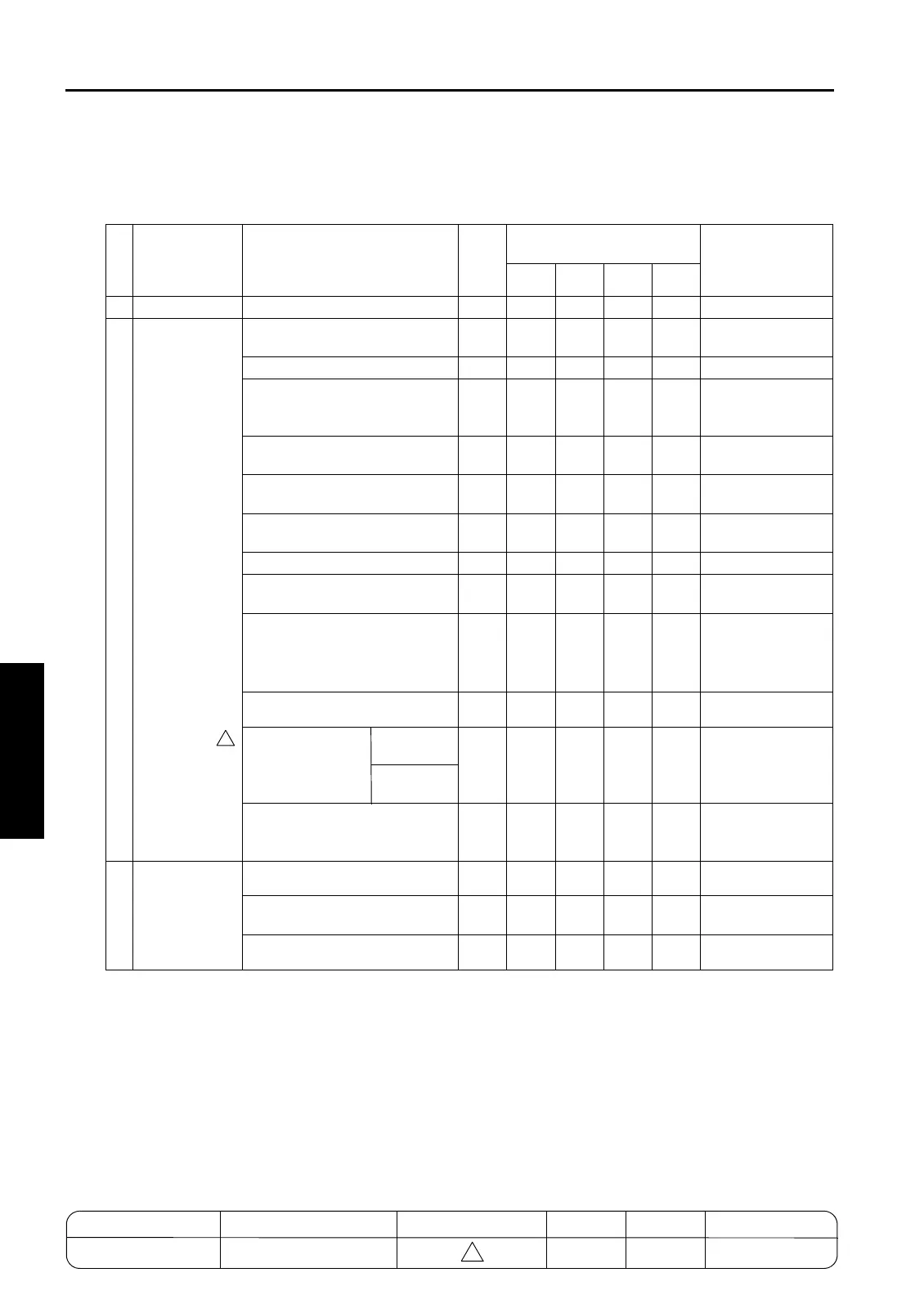

SERVICE SCHEDULE

4 SERVICE

[2] Maintenance Items

1. Main body (Every 250,000 copies)

NO

Classification Service item

Number

of parts

replaced

Implementation classifica-

tion

Materials/tools

used

Clea-

ning

Inspe-

ction

Lubric

-ation

Replace

-ment

1

Preparation (1) Image check

z

2

Drum unit (1) Charging control plate

56AA2503*

1

z

(2) Charging wire 56AA2509*

1

z

(3) Charging corona unit (back

plate and peripheral section,

PCL)

z

Drum cleaner/

waste/blower brush

(4) Charger cleaning base

56AA2540*

1

z

(5) Charger slide block

56AA2538*

1

z

(6) Charger cleaning block /U

56AA-253*

1

z

(7) Resin ring (

φ

2) 45AA2040*

1

z

(8) Charger cleaning block /L

56AA-254*

1

z

(9) Drum cartridge, bottom plate of

the developing unit, toner con-

trol sensor, separation claw

z

Blower brush/clean-

ing pad/A drum

cleaner is used only

when cleaning a

toner control sensor.

(10) Toner collection screw A

z

Blower brush/clean-

ing pad

56AA-213*

(7155/7165)

56QA-213*

(7255/7272)

1

z

*1

z

Electricity lubricant

(12) Cleaning blade (36 mode

blade setting mode)

56AA2010*

1

z

3

Developing unit (1) Developing bias armature

z

Blower brush/clean-

ing pad

(2) Developer (25 mode counter

resetting)

1

z

(3) Developing unit

z

Blower brush/clean-

ing pad

4

4-2

Note: *1 After replacing the toner guide roller, be sure to apply an electricity lubricant on the edge of the guide

roller shaft (on power supply pin side).

(11) Toner guide

roller

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE MANUAL Dec. 2003

7155/7165/7255/7272

4-2 REPLACEMENT

4

Loading...

Loading...