OTHER ADJUSTMENT

1 ADJUSTMENT

4

4

[34] FNS Adjusting the Magnets on Con-

veyance Guide Plate B (FS-111)

1. Tool

• Screwdriver (Phillips)

2. Adjustment method

a. Preparation

b. Adjustment

Step

Operation

4

Loosen the four screws holding the 2nd

stopper assembly.

5

Make adjustments by moving the front or

rear side of the 2nd stopper assembly

upward using the ticks for reference.

Skew pattern A: Move the rear side of

the 2nd stopper assembly upward.

Skew pattern B: Move the front side of

the 2nd stopper assembly upward.

6

Temporarily tighten the four screws hold

ing the 2nd stopper assembly, and put

the conveyance unit into the basis posi-

tion. Make a copy of the adjustment

chart to check for 2nd folding skew.

7

Repeat Steps 4 to 6 above until the 2nd

folding skew falls within the spec range

(2mm or less).

8

Tighten firmly the four screws on the 2nd

stopper assembly.

Step Operation

1

Open the front cover.

2

Check whether conveyance guide plate

B makes contact with the cushioning

rubber when the magnets are stuck to

conveyance guide plate A.

3

If conveyance guide plate B does not

make contact with the cushioning rub-

ber, remove the rear cover and carry out

adjustment as described below.

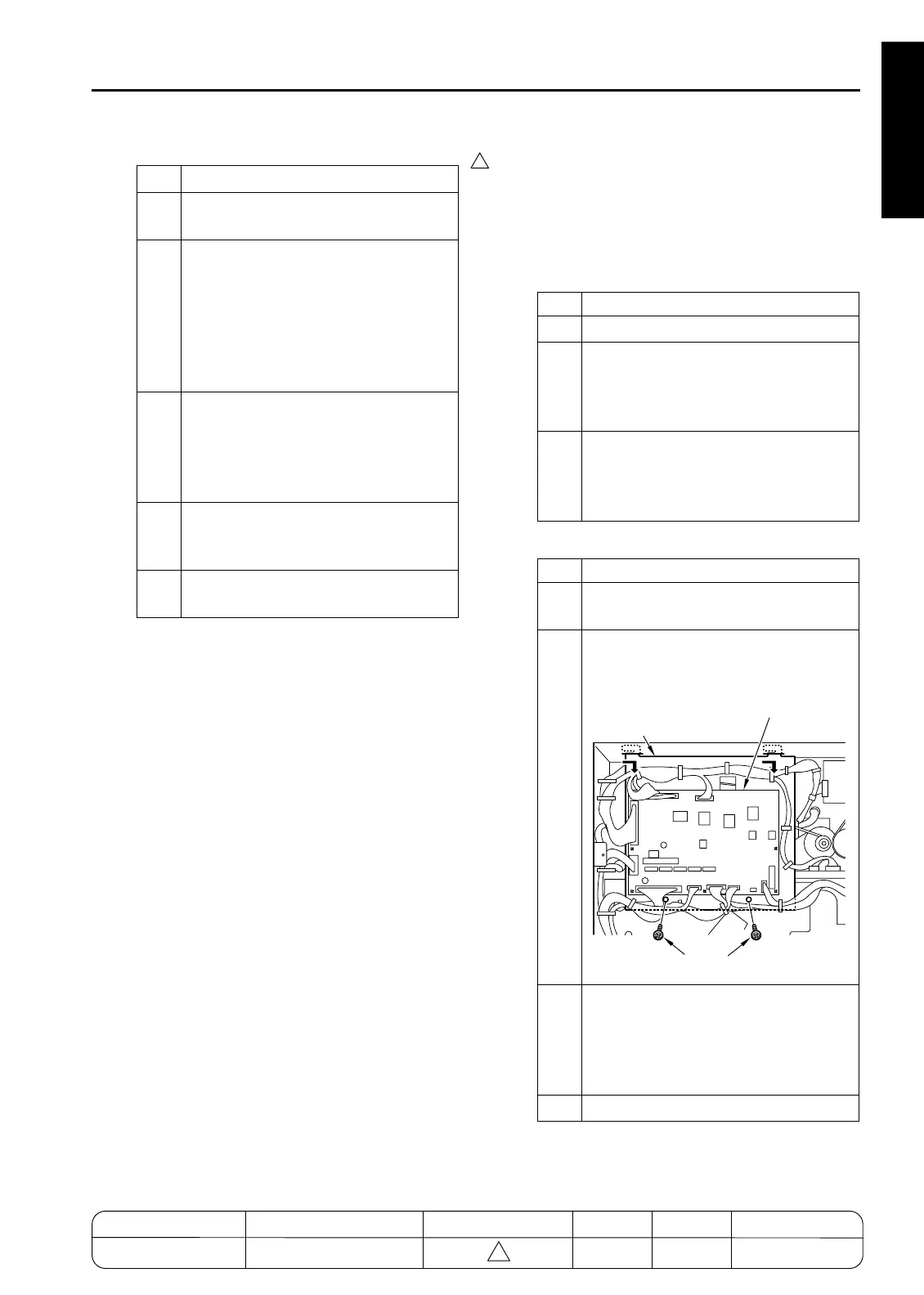

Step Operation

1

Detach all FNS CB (FNS control board)

connectors.

2

Remove the 2 set screws holding the

FNS CB in place. Remove the FNS CB

together with its bracket.

3

Loosen the 4 magnet-holding set screws

(two at the front and two at the back), and

move conveyance guide plate B all the

way in the direction indicated by the

arrow.

4

Remove the E-ring and the gear.

7272fs1015

Screws

Bracket

FNS CB (Finisher Control Board)

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE MANUAL Dec. 2003

7155/7165/7255/7272

1-137 ADDITION

Loading...

Loading...