Setting with magazine management

Make the following settings if you are commissioning the tool management with NC magazine

management:

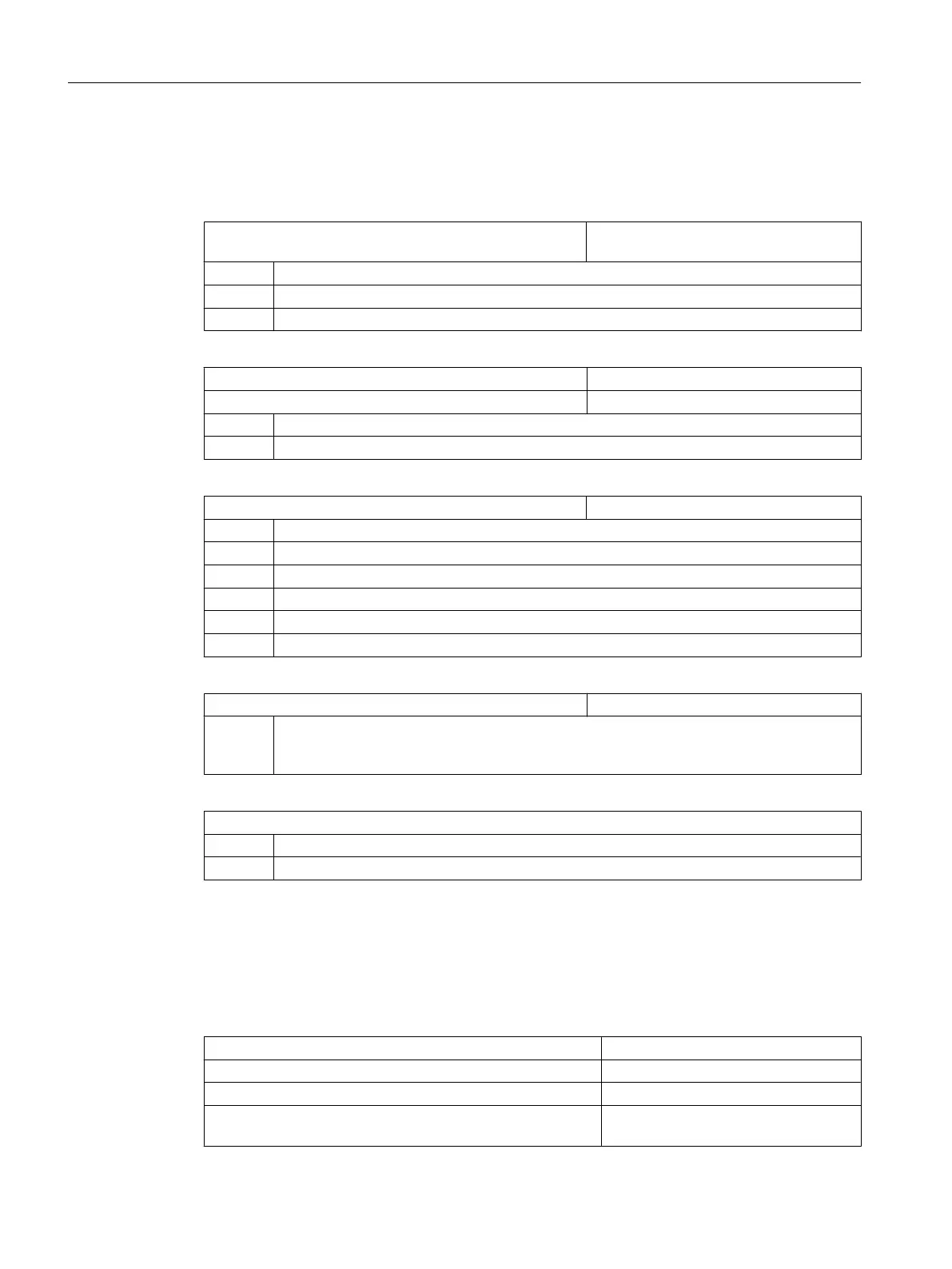

MD18080 $MN_MM_TOOL_MANAGEMENT_MASK Memory for the tool management is re‐

served step-by-step (SRAM).

= 03H

Bit 0 Provide tool management data.

Bit 1 Provide monitoring data.

MD20310 $MC_TOOL_MANAGEMENT_MASK Activating the tool management functions.

= 03H

Bit 0 Magazine management active.

Bit 1 Monitoring functions of tool management active.

MD17530 $MN_TOOL_DATA_CHANGE_COUNTER Marking the changed tool data for HMI.

= 1FH

Bit 0 Tool status change.

Bit 1 Tool remaining unit quantity change.

Bit 2 Tool data change service.

Bit 3 Magazine data in the change service.

Bit 4 ISO data in the change service.

MD28450 $MC_MM_TOOL_DATA_CHG_BUFF_SIZE Buffer for changing tool data (DRAM).

= 400 Number of entries in the buffer for the OPI change service for tool data. Dynamic memory

is used. This buffer is only created if either bit 2 or bit 3 is set in MD17530 $MN_TOOL_DA‐

TA_CHANGE_COUNTER.

MD19320 $ON_TECHNO_FUNCTION_MASK

= 10H

Bit 4 Enables the tool monitoring function with magazine management.

12.1.2 Configuring the access levels of the tool management

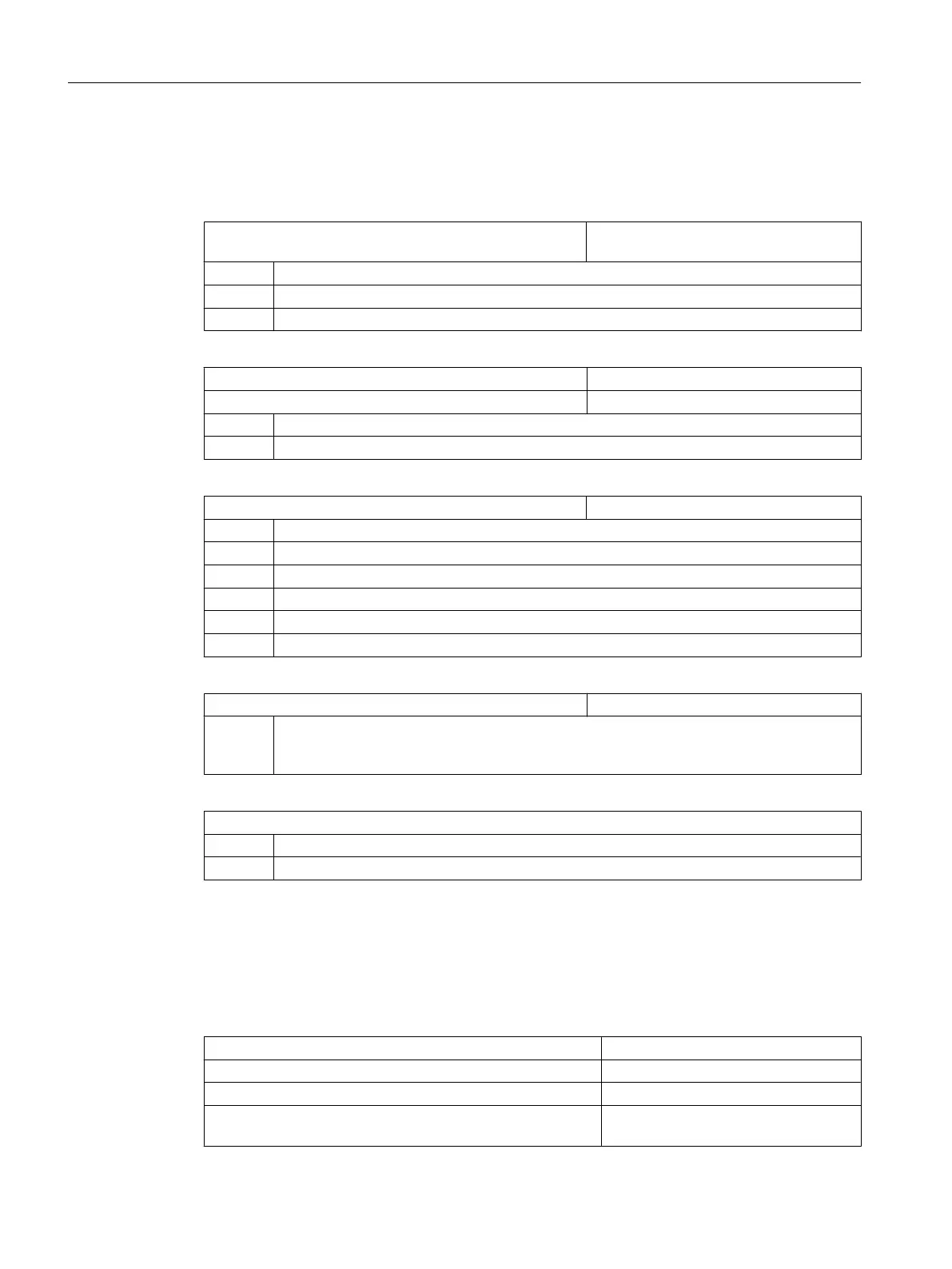

Access levels for selected parameters

MD51199 $MNS_ACCESS_WRITE_TM_GRIND Access level, write TM grinding data.

MD51200 $MNS_ACCESS_WRITE_TM_GEO Access level, write TM geometry data.

MD51201 $MNS_ACCESS_WRITE_TM_WEAR Access level, write TM wear data.

MD51202 $MNS_ACCESS_WRITE_TM_WEAR_DELTA Access level, restricted writing of tool

wear values.

Tool management

12.1 Machine data for tool management

SINUMERIK Operate (IM9)

164 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...