21.4.2 Technology cycles for milling

Milling function screen

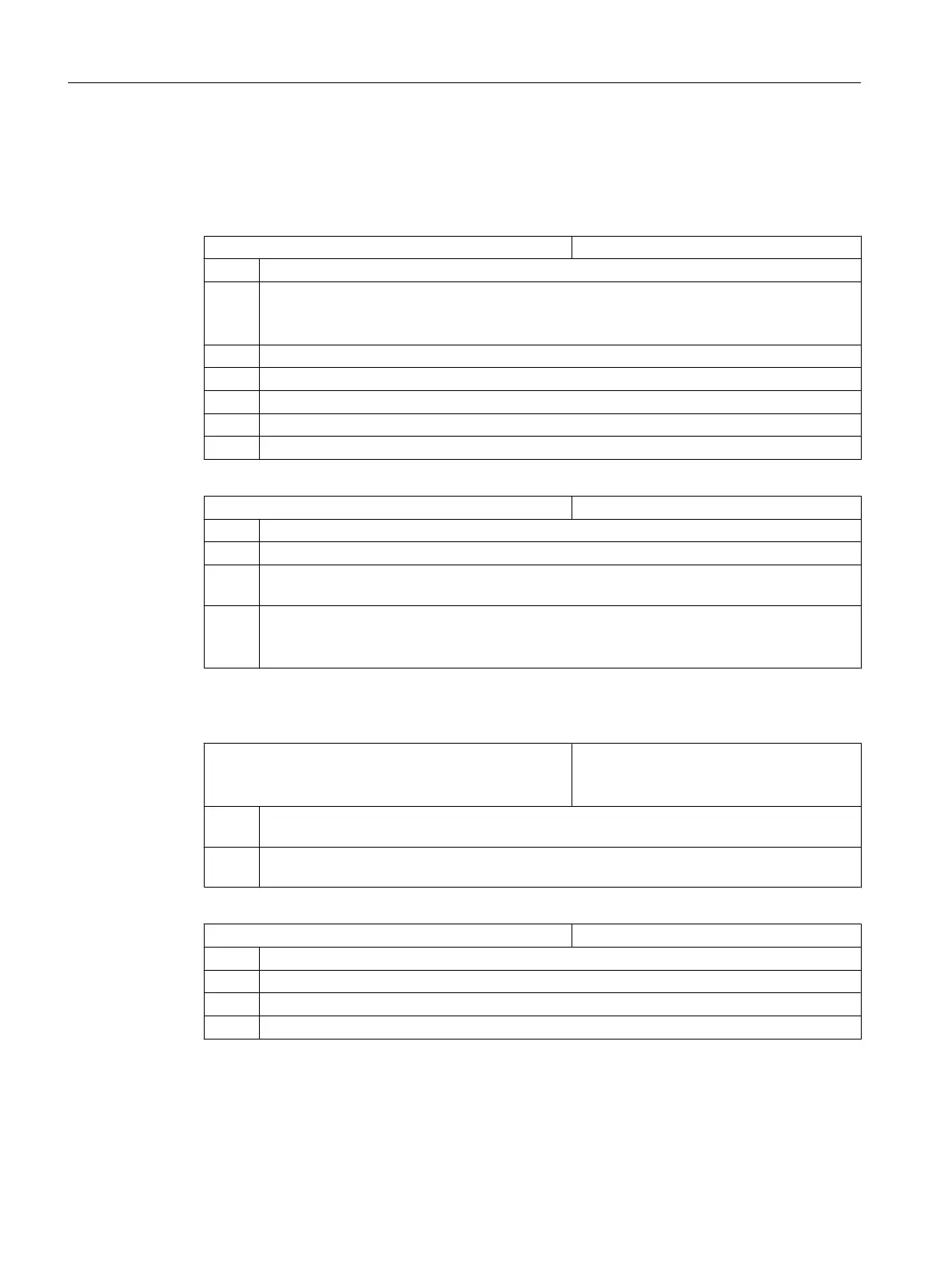

SD52214 $SCS_function_MASK_MILL Milling function screen

Bit 0 Enable cylinder surface transformation (ShopMill)

Bit 1 List table to accept blank (on milling machines)

(This bit only has to be set, if the machine has a rotary axis and a fixed table for accepting the

blank.)

Bit 2 reserved

Bit 3 Enable machining inside/outside

Bit 4 Enable spindle clamping (C axis)

Bit 5 Enable spindle control of the tool spindle via user interface

Bit 6 Enable spindle control of the main spindle via user interface

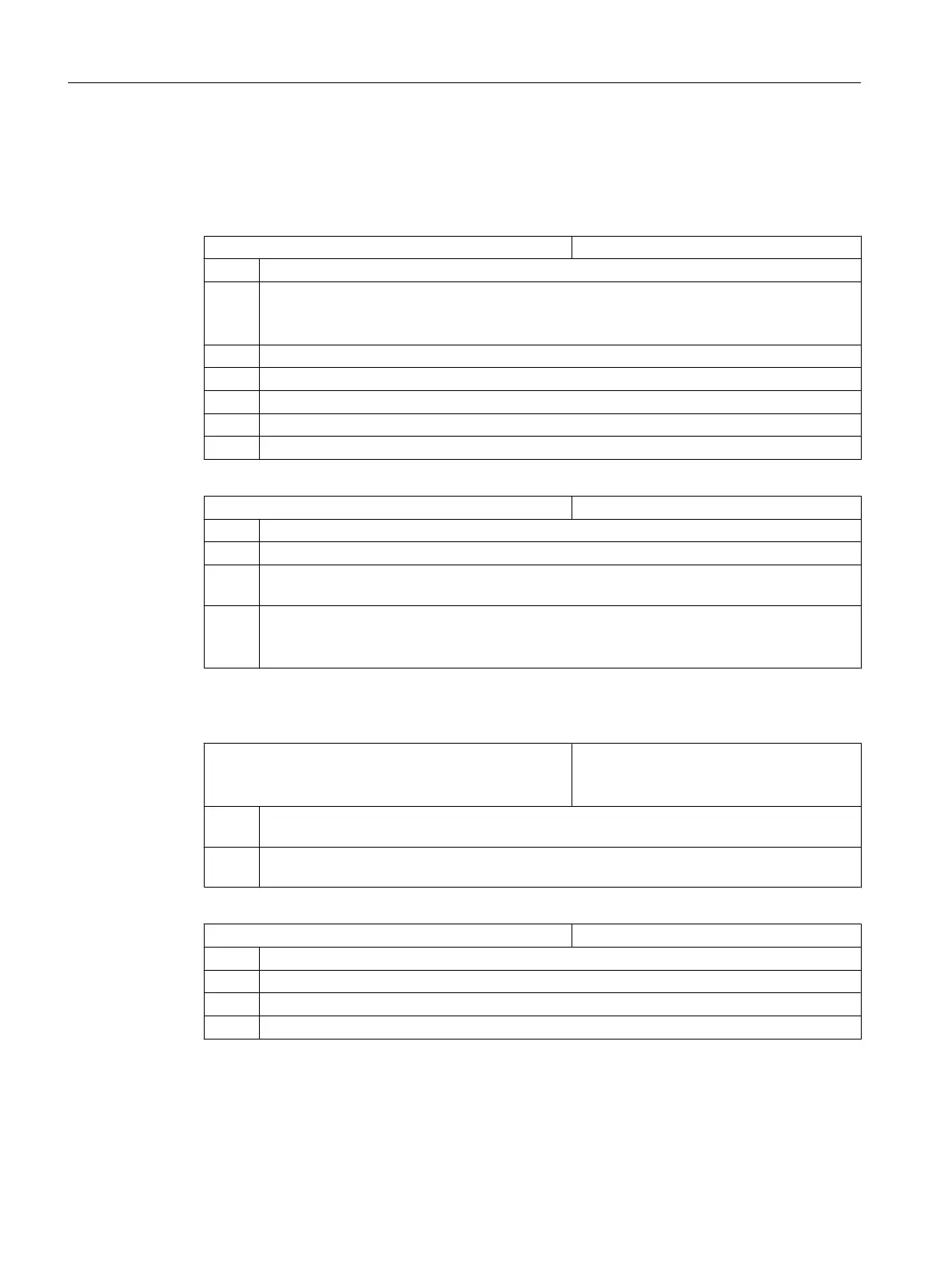

SD55214 $SCS_FUNCTION_MASK_MILL_SET Milling function screen

Bit 0 Basic setting, milling in climbing.

Bit 2 Depth calculation of the milling cycles, with or without safety clearance.

= 0 Depth calculation of the milling cycles is performed between the reference plane + safety

clearance and the depth.

= 1 Depth calculation is performed without including the safety clearance.

Bit 2 is effective in the following milling cycles: CYCLE61, CYCLE71, CYCLE76, CYCLE77,

CYCLE79, CYCLE899, LONGHOLE, SLOT1, SLOT2, POCKET3, POCKET4.

Contour milling (CYCLE63, CYCLE64)

SD55460 $SCS_MILL_CONT_INITIAL_RAD_FIN Finishing approach circle radius

The radius of the approach circle during the

finishing of contour pockets is affected.

= 0 The radius is selected so that at the starting point the safety clearance to the finishing allow‐

ance is maintained (default value).

> 0 The radius is selected so that at the starting point the value of this channel-specific setting

data to the finishing allowance is maintained.

SD55212 $SCS_FUNCTION_MASK_TECH_SET General function screen for all technologies

= 6

Bit 3 Delete programs generated by contour cycles (CYCLE63, CYCLE64, CYCLE952)

= 0 Generated programs are not deleted (compatibility as before)

= 1 Generated programs are deleted as soon as they have been executed by the calling cycle.

Technologies and cycles

21.4 Milling

SINUMERIK Operate (IM9)

518 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...