2.2 Configuration in the PLC user program

Loading configurations

The configurations created are transferred to the manufacturer directory of the control, with

the script and text file. Additionally, the corresponding PLC user program should be loaded.

Programming the equipment

Communication between the operator component and the PLC takes place in the PLC user

program via a data block defined by the programmer, in which 128 words are reserved for the

management of the devices. The description for the data block identifier is provided in Chapter

"PLC_INTERFACE (Page 192)."

The data block must be generated and loaded as a user block. The relevant block must be

declared to the EasyExtend function using the plc_interface tag in the "agm.xml" script.

Note

Compatibility

We recommend defining data block DB9905 as the PLC interface so that the scripts are also

compatible with SINUMERIK 828D.

Example:

<plc_interface name = "plc/db1000.dbb0" />

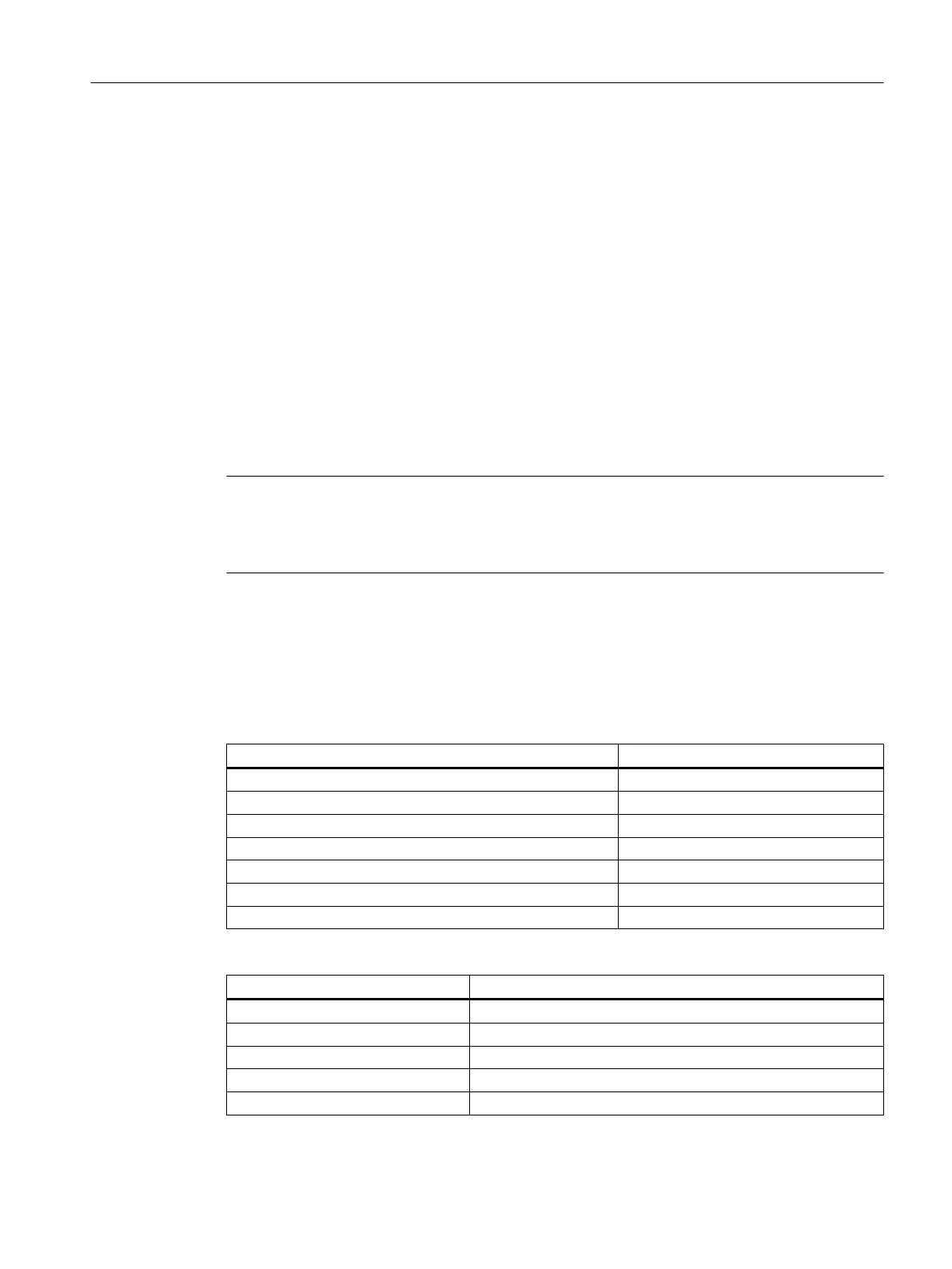

To create the block, data formats and symbolic identifiers from the following table can be used:

Data format/symbolic identifier Meaning

DBX0.0 Enable_1 BOOL Bit OFF OFF HMI → PLC Device has been started up

DBX0.1 Activate_1 BOOL Bit OFF OFF HMI → PLC Device is to be activated

DBX0.2 Deactivate_1 BOOL Bit OFF OFF HMI → PLC Device is to be deactivated

DBB1 Res_1 BYTE Unsigned 0 0 Reserved for future use

DBX2.0 IsActive_1 BOOL Bit OFF OFF PLC → HMI Device is active

DBX2.1 Error_1 BOOL Bit OFF OFF PLC → HMI Device has an error

DBB3 DeviceId_1 BYTE Unsigned 0 0 Unique device number

PLC words are assigned beginning with Device 1:

Data block Device designation

DB9905.DBB0 Device 1

DB9905.DBB4 Device 2

... ...

DB9905.DBB192 Device 49

DB9905.DBB196 Device 50

Generating commissioning dialogs

2.2 Configuration in the PLC user program

Easy XML

Programming Manual, 12/2017, 6FC5397-1DP40-6BA1 177