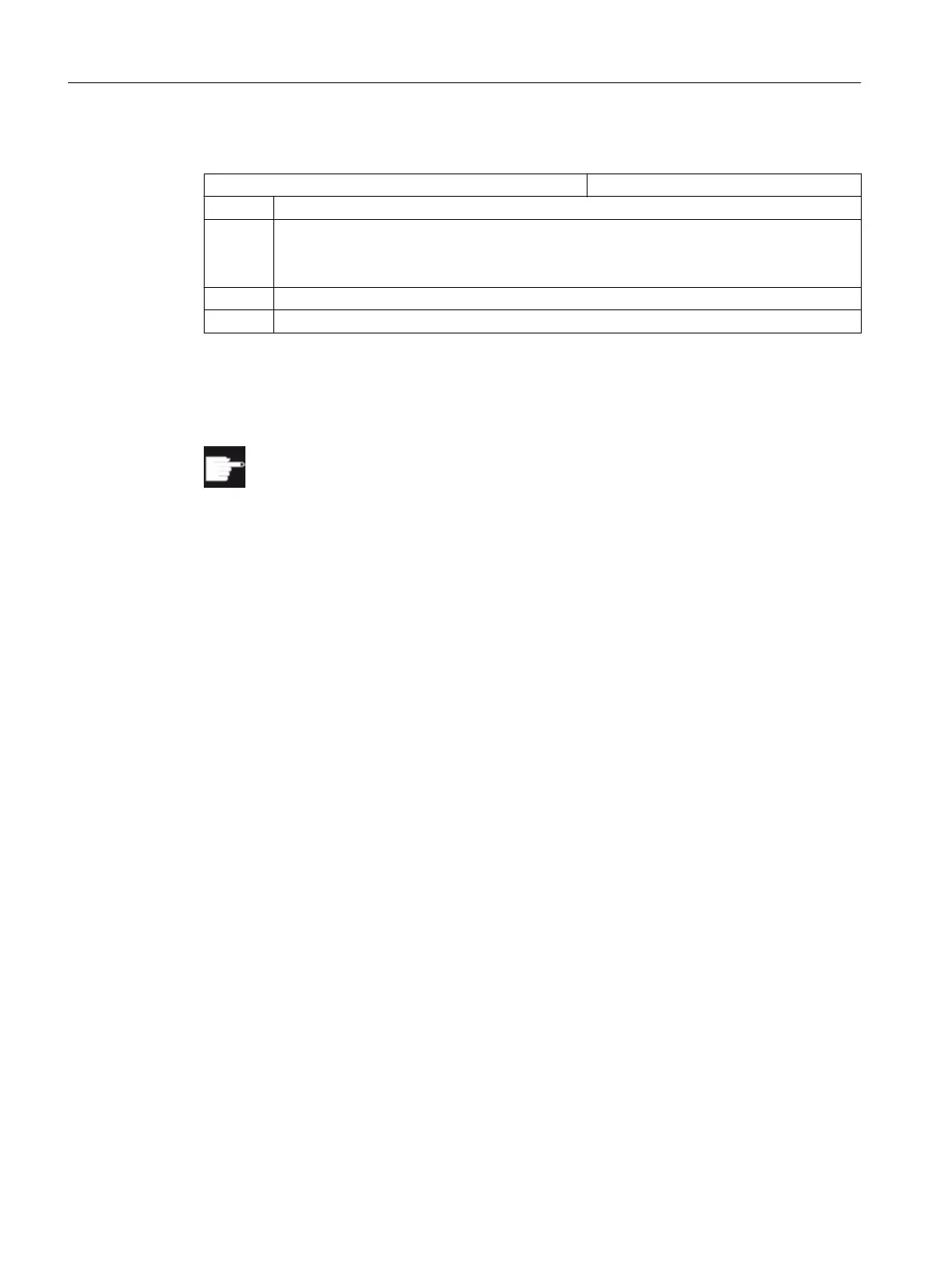

Channel-specific cycle setting data

SD55212 $SCS_FUNCTION_MASK_TECH_SET Cross-technology function screen

= 6

Bit 0 Tool preselection active.

The next tool is prepared directly after a tool change.

Note: For a revolver, the setting data must be set to "0".

Bit 1 Automatic calculation of the thread depth for metric threads.

Bit 2 Take the thread diameter and thread depth from the table.

21.4.4 Cylinder surface transformation (TRACYL)

Software option

You require the following software option in order to use this function:

"Transmit and peripheral surface transformation".

Precondition

● There must be at least one rotary axis at the machine.

● The milling tool must be radially oriented to the cylinder to be machined.

Function

The following groove machining operations can be performed with the Cylinder surface

transformation functions:

● Longitudinal grooves on cylindrical bodies

● Transverse grooves on cylindrical objects

● Grooves with any path on cylindrical bodies

The path of the grooves is programmed with reference to the unwrapped, level surface of the

cylinder. Programming can be realized using straight line/circle, drilling or milling cycles or

contour milling (free contour programming).

Technologies and cycles

21.4 Milling

SINUMERIK Operate (IM9)

522 Commissioning Manual, 12/2017, 6FC5397-1DP40-6BA1

Loading...

Loading...