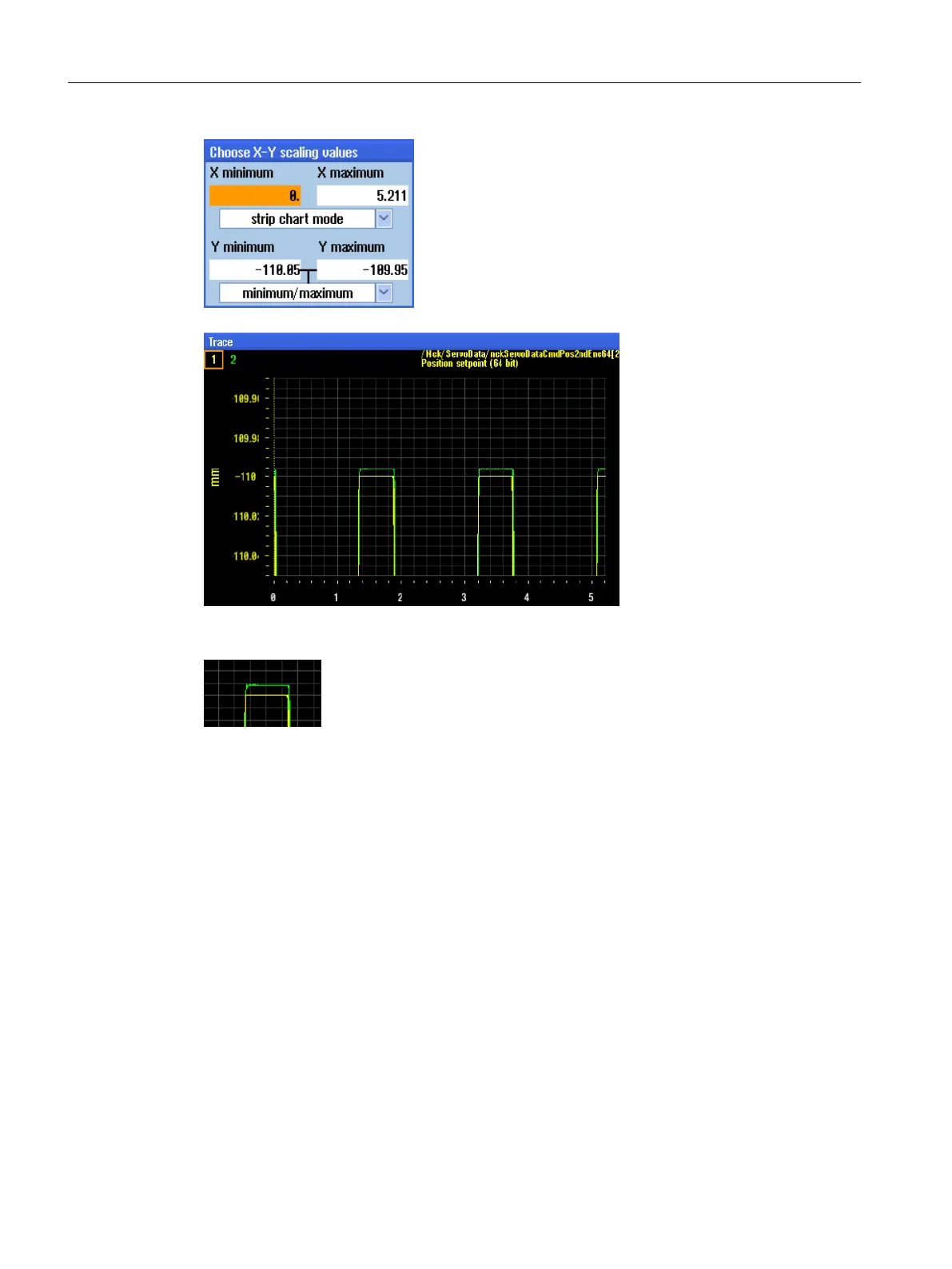

View in detail:

Position setpoint (yellow) and actual position (green) do not match because the position

controller is not active.

6.3.4 Optimizing the jerk setting

Tuning objective

The jerk must

be set so that the actual position is not exceeded. This is done by setting a jerk

value that is too high.

A jerk value that is too low can also be disadvantageous for the machine because it affects

the time required for positioning an axis. Without the position controller, the axis is positioned

without overshooting.

The remaining positioning error results from the position controller being deactivated and the

axis moves only with feedrate signals. An overshooting on reaching the position that results

from the mechanical system can be prevented by using a jerk limitation.

Tuning

6.3 Optimizing the axis jerk

CNC commissioning

188 Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3

Loading...

Loading...