8.2 Configuration in the PLC user program

Loading configurations

The configurations created are transferred to the manufacturer directory of the control, with

the script and text file. Additionally, the corresponding PLC user program should be loaded.

Programming the equipment

Communication between the operator component and the PLC takes place in the PLC user

program via data block DB9905, in which 128 words are reserved to manage a maximum of

64 devices.

Four bytes with the following meanings are used for each device:

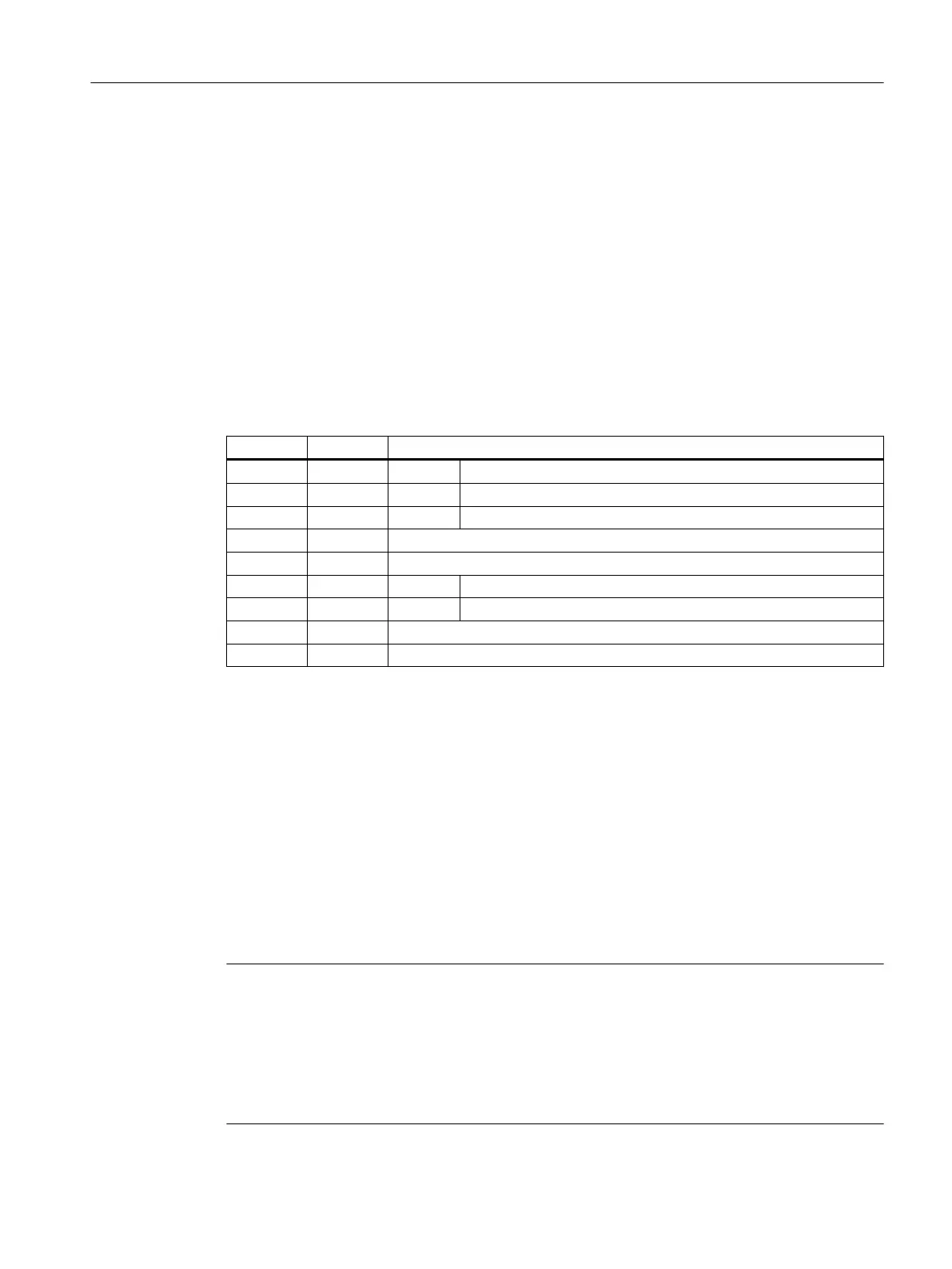

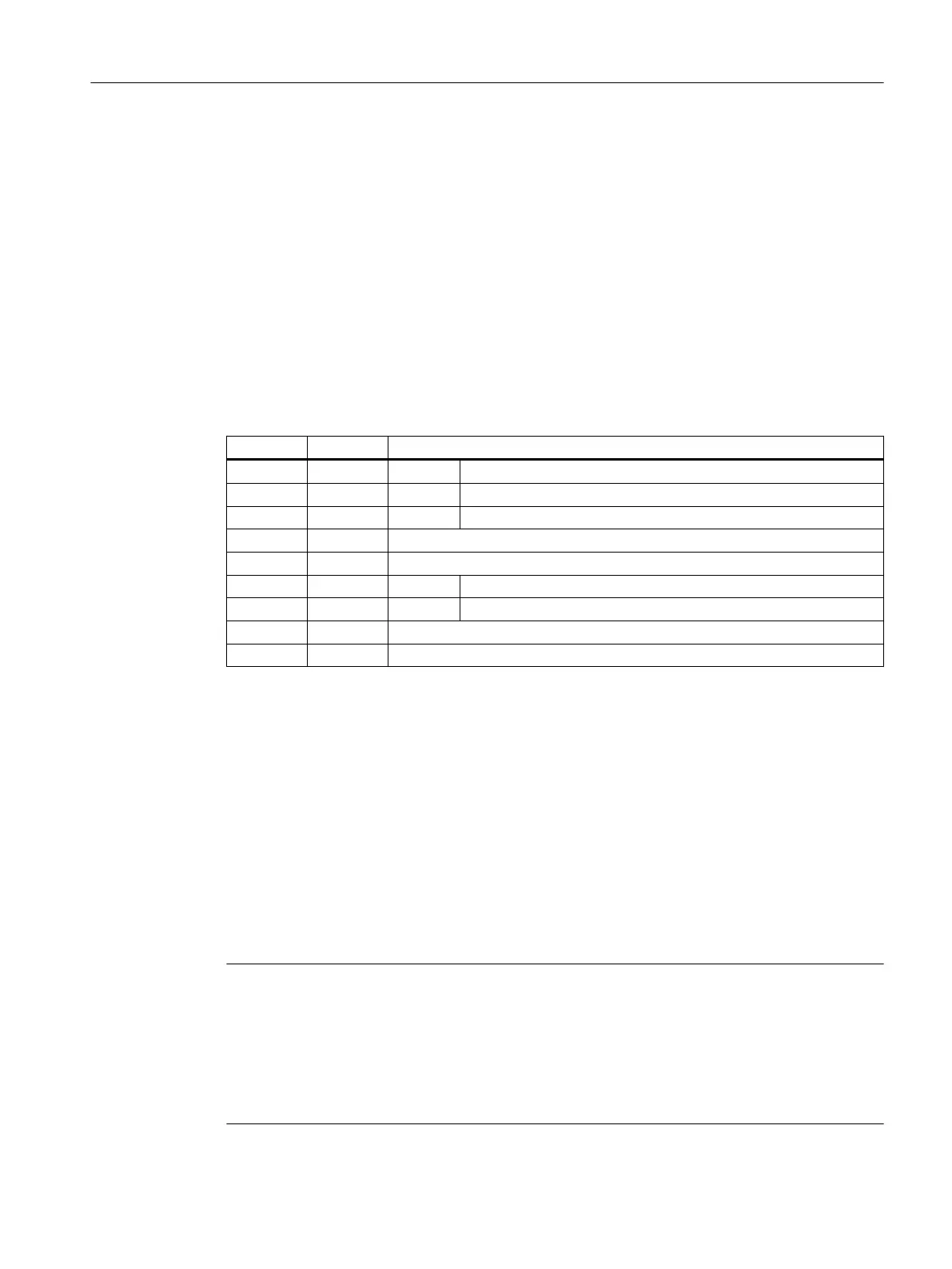

Byte Bit Description

0 0 == 1 Device has been started up (HMI acknowledgment)

1 == 1 Device is to be activated (HMI request)

2 == 1 Device is to be deactivated (HMI request)

3-7 Reserved

1 0-7 Reserved

2 0 == 1 Device is active (PLC acknowledgment)

1 == 1 Device has an error

2-7 Reserved

3 0-7 Unique identifier for the device

Adding axes

If the machine is extended with machine axes, it is important to install the drive objects (DO)

in a fixed sequence because the start-up archive contains the constellation of the machine

manufacturer's reference machine and cannot be applied if the sequence is changed.

It is recommended that the following settings be selected for the "control components":

● NC data

● PLC data

● Drive data

–

ACX format (binary)

Note

Commissioning archive

● In order to be

able to use a commissioning archive in the Easy Extend script, these archives

must be created without HMI data!

Changing the machine configuration

● Should there be any need to edit the drive machine data, this should be adapted in the

control first. This procedure should be repeated for all devices and constellations.

Easy Extend

8.2 Configuration in the PLC user program

CNC commissioning

Commissioning Manual, 10/2015, 6FC5397-3DP40-5BA3 239

Loading...

Loading...